I'm using this but if I had my time back I would use a different finish type, maybe Tung Oil or something similar. The veneer is much too beautiful to cover it in plastic looking stuff.

@Gowa I really disliked the Polycrylic when I tried it. Even when dry it still had a bit of haze to it. The Minwax water based poly is much better IMO if you want water based stuff, it has much better clarity, can look like a thin epoxy coat if that's what you're after.

I'm a big fan of tung oil, I use the Circa 1850 stuff. It's super easy to apply, smells somewhat nice (IMO) and always looks great. Downside is the finishing time and cure time as you need a full 24hrs between coats and then a couple weeks to fully cure. My first coat is real heavy so I let it sit 2 days before applying a second. scuff with super fine steel wool between coats, and it can takes 4-6 coats until the wood stops soaking it up and you get an even sheen.

Also, I used the contact cement method on one cab and the iron on wood glue method on the other. Contact cement has no issues but the wood glue had issues. When I put the first light coat of finish on the wood glue cab the veneer lifted from the substrate. I've had a heck of a time getting it in order.

@Gowa said:

Also, I used the contact cement method on one cab and the iron on wood glue method on the other. Contact cement has no issues but the wood glue had issues. When I put the first light coat of finish on the wood glue cab the veneer lifted from the substrate. I've had a heck of a time getting it in order.

I only use contact cement for my veneer work - it stinks but it works!

@Gowa said:

Ya, the Polycrylic was a bad decision.

Used it on one project long ago, very plastic coating.

Now I love Tried and True oil finishes.

You can mix their Danish Oil 50/50 with poly for a more durable finish, or just use the their oil and use your favorite poly over the top. https://www.triedandtruewoodfinish.com/

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

@R-Carpenter said:

Use catalyzed glues that are made for veneer and there will be no issues.. ever.

Could you please provide a name / link for a specific one? As someone who has struggled with wood glue, you definitely have my interest. The problem I always have with the wood glue iron-on method is bubbles where the glue didn't adhere.

@R-Carpenter said:

Use catalyzed glues that are made for veneer and there will be no issues.. ever.

Could you please provide a name / link for a specific one? As someone who has struggled with wood glue, you definitely have my interest. The problem I always have with the wood glue iron-on method is bubbles where the glue didn't adhere.

note: I use paper backed veneer exclusively.

I was not happy with using Titebond II for iron on veneer - had a couple of corner and edge problems. Went back to my standard Heatlock glue, and had no problems. I almost always use 2 applications to each surface, with possibly a 3rd layer touchup aound the edges. Have not had one problem with bubbles, edges or corners in many projects. Worth the cost!

I can't use contact cement, since my workshop is in the basement.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

As a relative veneering novice I've also had good success with HeatLock glue. I also recommend their veneer glue roller. Tom Zarbo has a few good Youtube videos about veneering using HeatLock.

I've yet to see Better Bond products in Canada, so I'll be using contact cement for my next veneer adventure. I didn't have good luck with iron in method, had splitting problems with maple, the heat stress and rapid dehydration isn't a good combination for raw veneer, you'd need paper backed at the very least for iron on method I've determined.

@dcibel said:

I've yet to see Better Bond products in Canada, so I'll be using contact cement for my next veneer adventure. I didn't have good luck with iron in method, had splitting problems with maple, the heat stress and rapid dehydration isn't a good combination for raw veneer, you'd need paper backed at the very least for iron on method I've determined.

Yeah, that's what I've heard about raw veneer. Gotta use contact cement or a cold press method.

My local hard wood shop has offered to do a cold press workup with some raw bubinga they have in

stock. Going to try that one of these days.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

@R-Carpenter said:

Use catalyzed glues that are made for veneer and there will be no issues.. ever.

Could you please provide a name / link for a specific one? As someone who has struggled with wood glue, you definitely have my interest. The problem I always have with the wood glue iron-on method is bubbles where the glue didn't adhere.

Well, after some disappointment in the quality of finish, I've decided to strip (sand) the Polycrylic from the cab and apply another type of finish. To further my disappointment, the Polycrylic doesn't sand like other finishes. It balls up in small plastic balls and clogs the sandpaper. This stuff is pure crap. It looks like crap and the workability is awful.

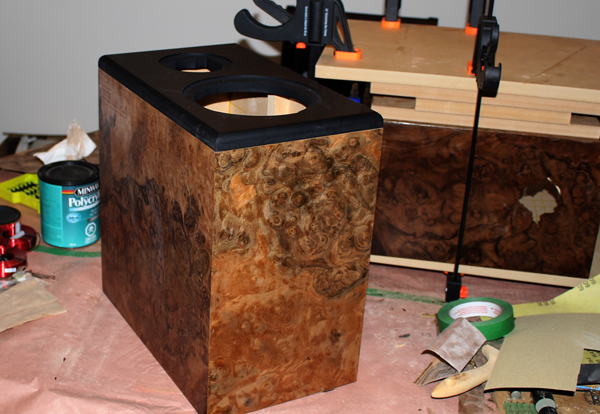

As you can see in the picture, the residue from the Polycrylic stays white even when wiped with a cloth or coated with another coat of Polycrylic.

Minwax needs to go back to the drawing board on this one.

This is not my first rodeo. In the past, I always used contact cement and Verathane or oiled. I will continue this in future projects.

It will be a heavy job to remove all the Minwack, but I'm determined to bring out this stellar veneer the best I can.

If you have some extra test material I suggest you try Dave Fred's technique. I have been using it now for a year or two and love the results. It's the 1:1:1 mix of boiled linseed oil, turpentine, and either gloss or satin oil based poly. Downside is that the turpentine makes the mixture stink! Upside is the fool-proof-ness and most importantly the final results!

I'm kinda stuck in this now and I will follow it through. Here's hoping my patience holds out.

By the way, that flat black paint is amazing. I like it a lot.

Comments

Pretty.

You've got an email from me

Working on the Safiniea.

I"m thinking about a black baffle also. What paint did you use?

Matte black

...and he never touched them again...

Strangely, I've been handling them to ensure matte stability and all is good so far. The look is fantastic. Very deep black.

SOLD

You beat me to it!

The people need more pictures!

I'll post a bunch when they are finished.

I'm using this but if I had my time back I would use a different finish type, maybe Tung Oil or something similar. The veneer is much too beautiful to cover it in plastic looking stuff.

Danish oil then oil-poly would work well.

InDIYana Event Website

@Gowa I really disliked the Polycrylic when I tried it. Even when dry it still had a bit of haze to it. The Minwax water based poly is much better IMO if you want water based stuff, it has much better clarity, can look like a thin epoxy coat if that's what you're after.

I'm a big fan of tung oil, I use the Circa 1850 stuff. It's super easy to apply, smells somewhat nice (IMO) and always looks great. Downside is the finishing time and cure time as you need a full 24hrs between coats and then a couple weeks to fully cure. My first coat is real heavy so I let it sit 2 days before applying a second. scuff with super fine steel wool between coats, and it can takes 4-6 coats until the wood stops soaking it up and you get an even sheen.

Ya, the Polycrylic was a bad decision.

Also, I used the contact cement method on one cab and the iron on wood glue method on the other. Contact cement has no issues but the wood glue had issues. When I put the first light coat of finish on the wood glue cab the veneer lifted from the substrate. I've had a heck of a time getting it in order.

I only use contact cement for my veneer work - it stinks but it works!

I agree

Use catalyzed glues that are made for veneer and there will be no issues.. ever.

Used it on one project long ago, very plastic coating.

Now I love Tried and True oil finishes.

You can mix their Danish Oil 50/50 with poly for a more durable finish, or just use the their oil and use your favorite poly over the top.

https://www.triedandtruewoodfinish.com/

Could you please provide a name / link for a specific one? As someone who has struggled with wood glue, you definitely have my interest. The problem I always have with the wood glue iron-on method is bubbles where the glue didn't adhere.

note: I use paper backed veneer exclusively.

I was not happy with using Titebond II for iron on veneer - had a couple of corner and edge problems. Went back to my standard Heatlock glue, and had no problems. I almost always use 2 applications to each surface, with possibly a 3rd layer touchup aound the edges. Have not had one problem with bubbles, edges or corners in many projects. Worth the cost!

I can't use contact cement, since my workshop is in the basement.

As a relative veneering novice I've also had good success with HeatLock glue. I also recommend their veneer glue roller. Tom Zarbo has a few good Youtube videos about veneering using HeatLock.

https://veneersupplies.com/products/Better-Bond-Heat-Lock-Veneer-Glue.html

I've yet to see Better Bond products in Canada, so I'll be using contact cement for my next veneer adventure. I didn't have good luck with iron in method, had splitting problems with maple, the heat stress and rapid dehydration isn't a good combination for raw veneer, you'd need paper backed at the very least for iron on method I've determined.

Yeah, that's what I've heard about raw veneer. Gotta use contact cement or a cold press method.

My local hard wood shop has offered to do a cold press workup with some raw bubinga they have in

stock. Going to try that one of these days.

FYI look at the reactivation temperatures. I use the Tite bond original yellow for iron on and vacuum bagging

http://www.webherrera.com/blog/2009/04/19/titebonds-franklin-internationals-iron-on-instructions/

https://www.vacupress.com/product/unibond-800-1-gallon-liquid-resin/

Unibond 800 for any sort of burls and veneers that are prone to movement.

https://www.vacupress.com/product/unibond-one-1-gallon/

1 is good for easy straight grain veneers that move less. I use both.

https://www.qualityvak.com/glue.html?gclid=CjwKCAjw_Y_8BRBiEiwA5MCBJoj717LVi-Ko-KrZTOI_8P4C7ZrSD-iB71e2ktsLyv92jm32ZdzMehoCRcwQAvD_BwE

This one is sort of industry standard. Very rigid glue line. Mixed with water by weight.

Well, after some disappointment in the quality of finish, I've decided to strip (sand) the Polycrylic from the cab and apply another type of finish. To further my disappointment, the Polycrylic doesn't sand like other finishes. It balls up in small plastic balls and clogs the sandpaper. This stuff is pure crap. It looks like crap and the workability is awful.

As you can see in the picture, the residue from the Polycrylic stays white even when wiped with a cloth or coated with another coat of Polycrylic.

Minwax needs to go back to the drawing board on this one.

This is not my first rodeo. In the past, I always used contact cement and Verathane or oiled. I will continue this in future projects.

It will be a heavy job to remove all the Minwack, but I'm determined to bring out this stellar veneer the best I can.

If you have some extra test material I suggest you try Dave Fred's technique. I have been using it now for a year or two and love the results. It's the 1:1:1 mix of boiled linseed oil, turpentine, and either gloss or satin oil based poly. Downside is that the turpentine makes the mixture stink! Upside is the fool-proof-ness and most importantly the final results!

I'm kinda stuck in this now and I will follow it through. Here's hoping my patience holds out.

By the way, that flat black paint is amazing. I like it a lot.