Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

SB Acoustics SB12PFC25-04... #nofilter

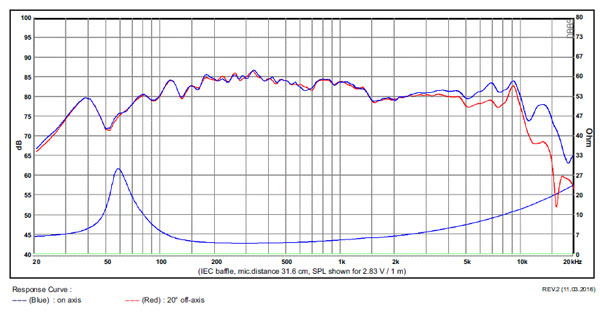

Sometimes I just feel like completing a project without all the hassle. I saw these drivers a while ago at Madisound and thought the FR was interesting in that it has a reasonable BSC shelf built right in and decent extension out to 10kHz, making them an enticing option for a full-range, no-filter project. At $23 a pop I grabbed a pair and they've been sitting on a shelf for a while.

I also wanted to try my hand at building a box with pre-veneered plywood and all edges mitered, so I grabbed a 2' x 4' panel of 3/4" oak plywood from Menards and built the biggest pair of boxes I could get out of it. They ended up being 11.25" x 8.75" x 7" with 0.22 cu ft of gross volume.

After a little box modeling, I settled on an Fb of 60Hz (with a 1.5" diameter x 5" long port) which gives a little oomph to the bass right before rolloff and gives an F3 around 56Hz. I had some 3D printed port flares for this size port hanging around and used them, mostly for a nice transition with the veneered exterior. I surface mounted the woofer because fuck that.

I still need to finish them, but per my usual, couldn't wait to get drivers in and listen. Overall, they perform as expected, with a very nice tonal balance when placed on stands - the built-in BSC worked a trick. The highs are definitely lacking as well as the deep bass, but the bass they do have is impressive. I threw a lot of watts at them with some bass heavy tracks and they kept their composure pretty well. Nothing I'd want to listen to every day, but it was nice to knock out a cheap, quick project.

Comments

Mark at Meniscus recomended that I try what you just did. He had used them on a customers project and was really impressed with how well they did. I now have 2 pair waiting for me to give them some attention. Fortunetly I have a jig made to recess them already done.

Did you take any measurements?

Great looking build!

I used the SB16pfc - same odd frame shape - and really like the sound. I also surface mounted mine, doubtless it has some effect on the tweeter response, but it's just too hard to flush mount that shape.

The frame has now been replaced by a round one but the whole PFC series still seems like excellent value.

Your cabinets look extremely good!

Geoff

I haven't taken any measurements, because I was never going to apply a filter no matter what the outcome. I'm a little curious about the final on-baffle response though. Maybe I'll throw it in front of the mic next time I'm measuring something else.

Yeah, I just saw Mad is carrying the round frames now. I can't say I'm a huge fan of the series, but they do offer a lot of bang for the buck. The cabs turned out pretty good, with less than 1mm gaps even on the worst edges. I need to run some wood filler along the edges and a couple of spots where the veneer chipped out (it was pretty cheap material overall), but once I do, they'll look pretty clean.

Sometimes you can put wood glue in the gaps and"burnish" the edges together. This will at least lessen the gaps before you finish.

I bought a digital tilt gauge and use it on my table saw all the time, really impressive how accurate they are considering how inexpensive they are.

I think my angles were dead nuts, but going from 4 mitered panels to 6 not only requires perfect angles, but perfect sizing of all panels in perfect square. If any of those three things are off on any of the panels, let alone multiple panels, a gap will result along some edge. I came up with a decent process with a sled and stop blocks so that all panels were square and cut to identical dimensions, but I think registering my fence against the flimsy knife edge of cheap veneer probably introduced some error that stacked up.

If you did want to recess those drivers I have a file that could be 3d printed into a router template. Let me know if you would like it.