Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Routers and Dust collection for the anal shop operator . . .

Looking for feedback on the best dust controlled routers on the market and dust collection systems to handle the mess those love/hate devices create.

Right now I have a Craftsman 2-1/4 HP router that does a fair job of collection while connected to a shop-vac (6.5HP) going through an Oneida Dust Deputy 2.5 cyclone separator. --> https://www.oneida-air.com/dust-deputy-2-5-inch-deluxe-cyclone-separator-kit

It's just OK and the hose connection is clumsy as it exits at 90* from the base with an overly restricted air flow at the pick-up-point- its a PITA and I have to hang the hose from the ceiling while getting tangled up in the power cord as I side-step around the little routing table/bench but still fine dust seems to show up on my shelves and PC gear - I can't live with this in my conditioned shop space.

This 2-1/4 HP Triton seems to have much better airflow configuration through and OUT of the motor (90* to the bit axis) https://www.amazon.com/Triton-MOF001-Precision-Plunge-Router/dp/B00779NCPM/ref=asc_df_B00779NCPM?tag=bngsmtphsnus-20&linkCode=df0&hvadid=80676783972125&hvnetw=s&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4584276310319910&psc=1

Now, concerning dust collection systems, what I have done is to get rid of the need for recycling the shop air and just blow the dust out the side of the building and this keeps the pressure drop to zero but I can only use it that way with the Miter saw and table saw when the weather is good/dry and not too cold or hot outside with a screened/filtered window open. But most of the time the weather doesn't cooperate while living here in the deep South.

So, I have my eyes on this --> https://www.oneida-air.com/dust-collectors/personal-shops/supercell-high-pressure-wall-mounted-hepa-cyclone-dust-collector-230v

Now, what are your thoughts on the hand-held router with the best dust collection/control design? (I think this is the critical device to focus upon right now).

Comments

You need to manage/ confine the particles to a particular sized space then ensure that open area has a velocity greater than 100 feet per minute. Nothing is going to capture particles coming off a 20,000 RPM router before you can slow them down physically. I designed several dust collection systems for composite aircraft part trimming.

I bought a Dewalt router in 2020 and like it. The dust collection comes straight out of the top and I just hook it up to a small shop vac. Having the dust collection hose coming out the top works really well with Jasper jigs.

https://dewalt.com/product/dw618pk/2-14-hp-maximum-motor-hp-evs-fixed-baseplunge-router-combo-kit-soft-start?tid=577361

Ron

This is the router I have as well and I've always been impressed with the dust collection features. Works well with a 1.25" hose suspended from "above" connected to a regular ol' shop vacuum.

Jhollander - I used to do a lot of Level-3 Bio-laboratory commissioning and aircraft [F22 program] paint booth mechanical control systems and understand the air-flow/pressure differential requirements of directing particulate matter but I don't have the funds that the NIH or Lockheed have at their disposal within my 24x36 mobile classroom building, now shop on the other end of my little 20 acres in the sticks.

I have focused/located the dust producing/collection-equipment tools to a corner of the space but without creating some sort of air curtain/drapes around the routing area with filter and return ductwork all the way to the other end of the shop I need to move outside for hand-held routing but there is no suitable space out there in the grass for this work.

Maybe I am just complaining but I am still looking for solutions.

Triton has figured out what I have been trying do with router airflow modifications in that they now eject the exhaust air from the router motor at 90* from the cutter axis which is a huge move in the right direction and the shielding they placed upon it is another plus - just wondering if you guys have that [Triton] router and what your findings-are in a confined space with a shop vac connected to it while cutting MDF and natural wood material, Sir.

Thanks for posting that little bit of your background here for us as it makes directing questions to those with knowledge we seek much easier.

Best!

I have the big Triton in the table, and feel the dust collection is superb just being extracted by a HD Buckethead vac.

InDIYana Event Website

Wolf - are you using just the 1-1/2 hose connection to the dust port on the Triton to the vac in your table set-up or something more?

I ask because I bought and assembled a new table with the 3-1/2 HP Triton router recently but have yet to cut any material with it.

Mother nature provides all the dust collection I need.

Probably have a nice concrete driveway and a garage . . . and nice Northern low humidity weather . . . im on grass/gravel in the deep South . . .

There is no such thing as low humidity weather in the Midwest.

Then we are equals concerning the weather except that it has been raining here constantly for over 2 f'n years.

+1

Bah!

Being well grounded in wet grass as I eye storm clouds daily doesn't motivate me . . . Lucky bastages . . .

If it's just an open table, consider building a closed cabinet. I'd guess 75% of the dust from mine (Triton) ends up in the cabinet, making it easier for my dust collector to collect what's left.

I have a shop vac and Harbor Freight dust collector, each with an Oneida Cyclone, but right now my breakers are weak in the garage so I can't run them both at the same time.

I did get the dust collection enclosure for the router table but also got the direct hose kit to the router base because I can't recycle shop dust air - it all goes outside and sucks the conditioned space out - I need to test it soon with the hose kit to the shop vac/cyclone.

Aside --> Finally got my new bandsaw up and running and trimmed/cleaned up a pile of 100+ YO rough sawn walnut my dad gave me about 40 years ago . . . got more up in the tractor implement shed yet to dry indoors . . .

Breakers are cheap, man - just make time to replace them - I keep spares around for the ones that don't have wall switches for the loads (Dust collector).

Thanks for the post.

I use the Festool dustless system for hand routing and sanding the plus is that it’s portable so I can do indoor house work and create less mess to clean up. The downside is it’s very expensive.

https://www.jfcomponents.com/

Got a link, Sir?

I'll look but may not buy but I love seeing designs . . .

If you have your eye on a $2700 dust collector, your in Festool territory.

There was a second half of my post that got lost, I'll post pictures this weekend.

I use a sink drop 1.5" tube into the vac.

InDIYana Event Website

I have a Bosch router table with a Triton router. It has a big vacuum hose fitting that draws air through the opening in the fence that works well for keeping the dust down. I don't use the hose fitting on the Triton and have a little dust under the table that I vacuum up by hand.

Ron

The dust collection attachment on my Bosch router is ok for when i'm cutting circles in baffles etc - I would say it catches 80-90% of the dust using a shop vac. My router table has the dust port on the fence and the router is enclosed in a box - with the dust collector hooked up to the fence and the box it captures almost all the dust that the router makes.

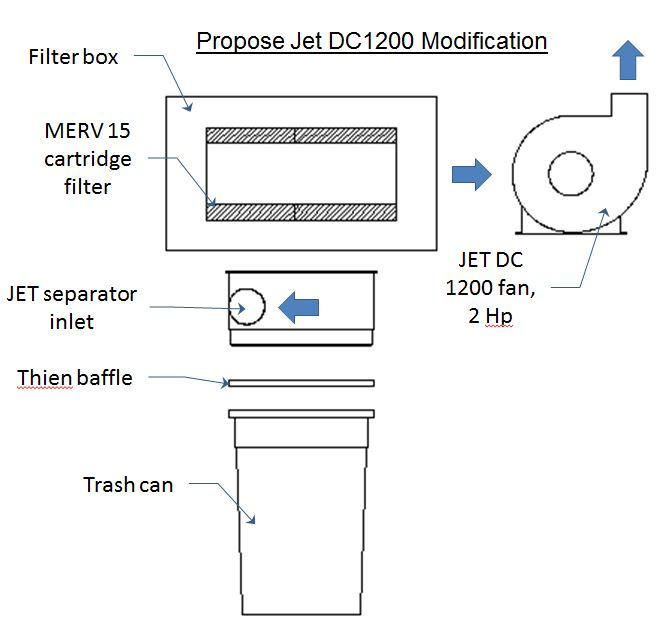

I use a combination of HEPA Shop vacuum or House vacuum with a 2 hp modified Jet Dust collector with a 95% efficient MERV 15 filter. I modified several cardboard boxes to capture the router or sander particles. My shop is inside my house so I have to control the dust so nothing escapes

Nice setup John.

Love the Magnehelic Static Pressure Gauge, man!

The cardboard shrouds/experiments are awesome as well.

Where in that Dust Collection (DC) system is that final filter located - I don't see it your pics.

(I have a rather large filter like yours languishing in a storage room but the pressure drop across it and the cyclone separator combined just reduce the airflow too much unless I run (2) 2 HP blowers in parallel and that takes too much amperage/room to handle it all. (Which is why I just stopped trying to recycle/filter conditioned shop space air).

Cool setup John 👍

First time seeing the garbage can collector. I like that! The bags on the cnc fill up quick that would be much nicer.

https://www.jfcomponents.com/

The final filter is in the box on top of the round part of the dust collector. The fan was moved to pull through the filter. The Jet circular section was modified with a Thien separator and a plywood ring was added to the bottom for the trash can. I crushed the plastic trash can in my first design.

From 2015