Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Who's Online (0)

Converting Driver Rebate Scans/Designs to CNC ready files . . .

Undaunted, I looked into this useful process and came across the following information:

https://www.scan2cad.com/blog/tips/how-to-convert-an-image-for-cnc/

More here:

https://duckduckgo.com/?q=converting+scans+into+CAD+drawings+for+CNC&atb=v357-1&ia=web

https://duckduckgo.com/?q=CNC+router+services&atb=v357-1&ia=web

Any informed/experienced opinions/direction for the members/lurkers here welcomed.

Comments

I use convertio to change files into the format I need. Then use my CAD program of choice. I find that the biggest issue is accurate drawings. A lot of dimensional photos are only accurate in the dimensions not the drawing.

Even when measuring frames of drivers in-hand I have found some significant dimensional anomalies. Getting the correct shape and then the correct amount of clearance is a bit of art.

Most driver data sheets include a basic cad drawing right? And most drivers frames are basically constructed from a circle and a square right? 5 min in CAD sketch and done. We’re not talking about complex shapes here so raster to vector software is a bit much for this task.

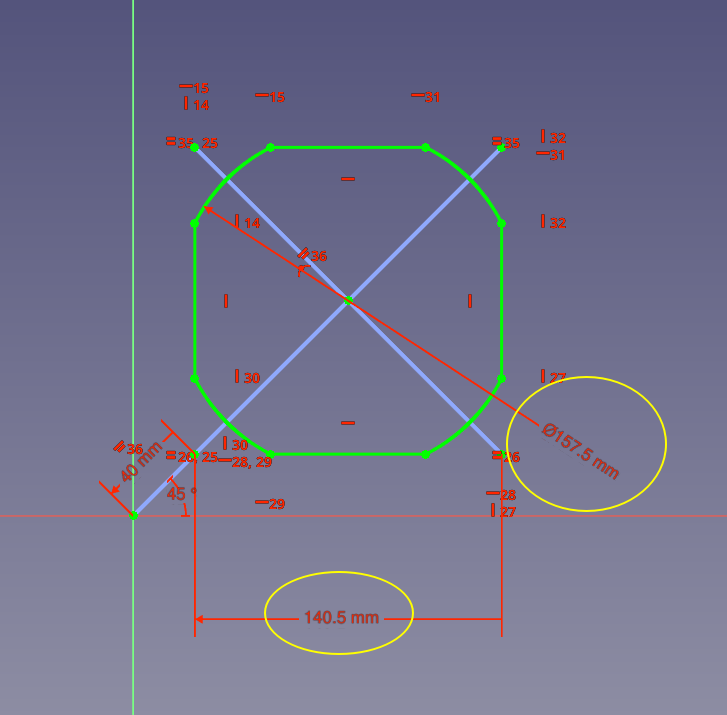

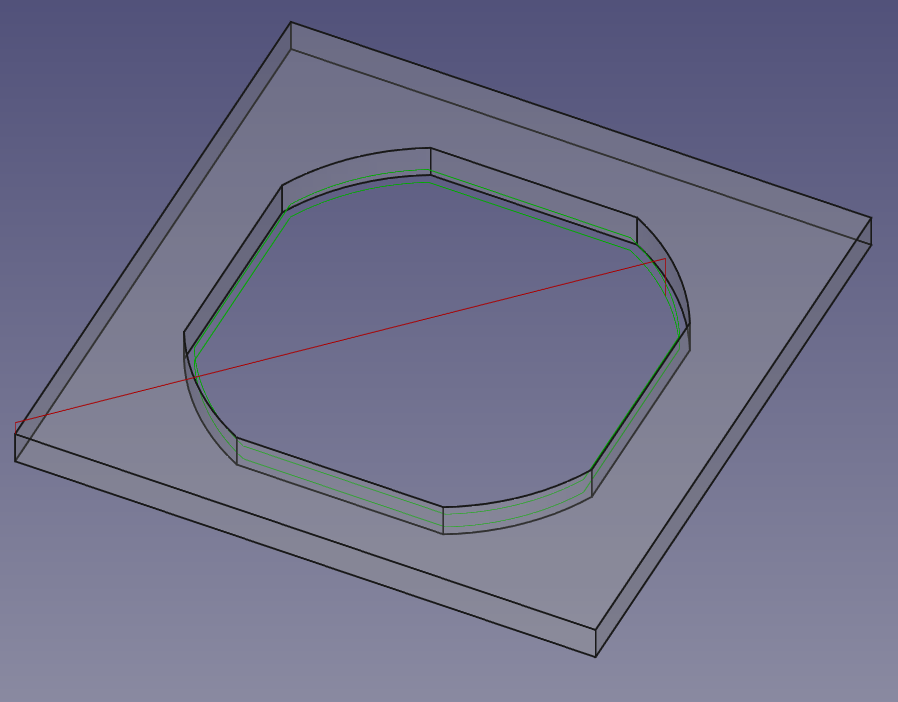

Here's a "round square" frame, just adjust 2 dimensions to customize it for any driver dimensions.

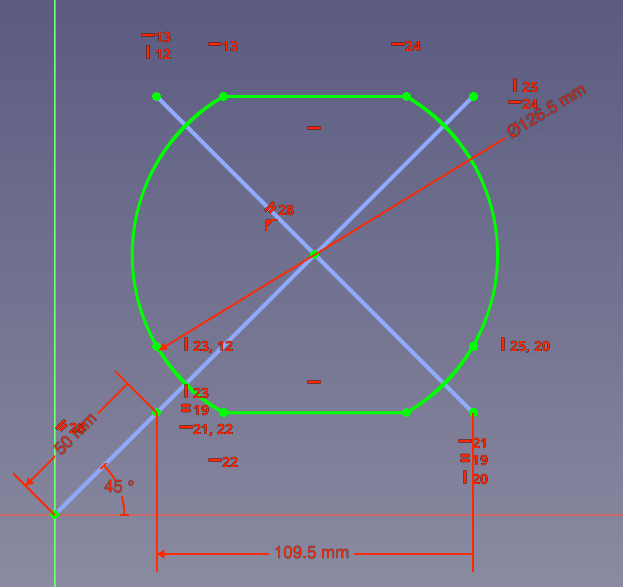

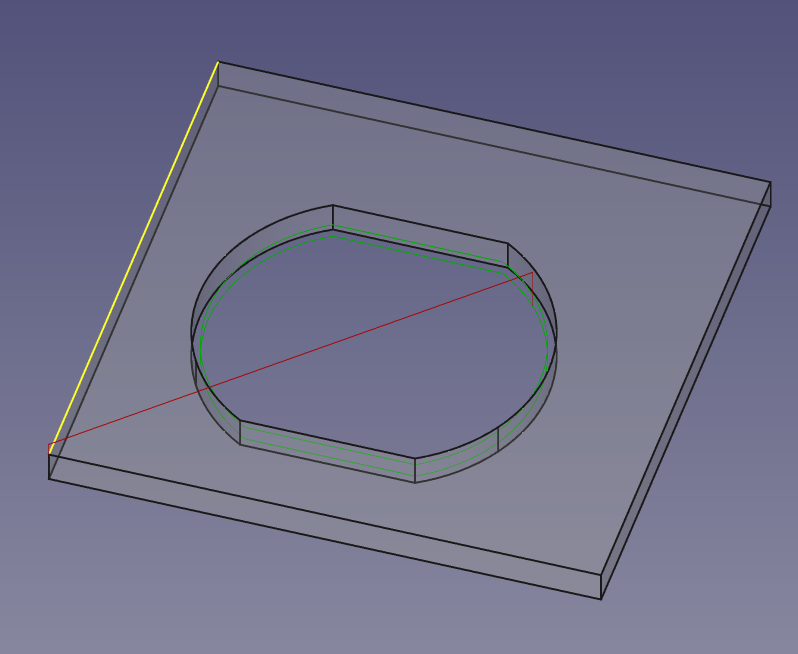

Here's a truncated frame.

FreeCAD files attached so the work is already done for you. Made with FreeCAD 0.21.1.

Tracing an image into a CAD sketch is also easily done, but you need at least one known dimension in order to scale the image. Here's 2 videos on the subject for FreeCAD 0.21:

That is so cool with the parameterization.

I could not get Freecad to run well for me, so I am trying to do the same thing in Fusion360.

the ability to export to a CNC is primary though, which I think is $$ in Fusion360.

Basic CAM toolpath stuff I though was baked into Fusion, but you pay extra for the more advanced features. I try to stay away from Fusion because I’m not a fan of the cloud based subscription platform.

FreeCAD includes some CAM toolpath functions, a bit clunky to get set up but works well once you figure it out, green lines in the above photo are the toolpath, can be exported directly to gcode.

Of course, you can always export the drawing as SVG or DXF and use with any CAM software you like.

Here's the same files as above, with a toolpath set up for 1/4" end mill.

I've tried Fusion and found it to be excruciatingly slow on anything more complex than 2D. Fusion also get pricey as you start adding module for rotary machining or various 4d machining strategies. Decided to stay away from Autodesk.

Above templates cut out today out of acrylic, about a 10min job once the machine is set up.

Something a bit more exciting, waveguide shape I designed in FreeCAD, completely parametric to adjust the shape to perfection. First test cutout on some scrap I think is a big success. This one is about 20 min because I do 2 passes. First pass is rough cut with 1/4" end mill to remove the bulk, then it is spiral cut with a 1/4" ball end for the surface. I could increase the step over or use a smaller bit for finer finish, but this will clean up smooth with 5 min of hand sanding.

Are you just antagonizing we here who were born, BC? (Before Computers).

Can I pay you to do templates in acrylic for me?

No, go find someone local. Maker spaces, Men's Sheds, local classified ad, you'd be surprised what you might nearby find that doesn't require international shipping.

I'll whip up a CAD file for you if you really want, but I'm not interested in cutting and shipping templates.

OK, thanks for your assistance where applicable and your no-BS feedback.

If you have something you need and it’s just not not to do with a router I’m here in the states. Like I said in the other post it’s mostly just a circle and square.

https://www.jfcomponents.com/

"If you have something you need and it’s just not not to do with a router I’m here in the states. Like I said in the other post it’s mostly just a circle and square."

Dude - can you tell me what this means, please? (I'm not trying to be an ass but I don't understand what you are actually offering to assist me with that I cannot eventually do myself with a hand-held-router based upon this response).

You have a programmable router, I do not and my back and shop are just not at the level that yours is . . .

Best wishes, man.

In simple terms this means that I am in the states if you need help with a template I’m here. I have a CNC machine and how to use it but I do not see that there is any reason to make a template and trying to sell them.

https://www.jfcomponents.com/

OK - thanks for the clarification and the offer of help.