Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

woodworking question

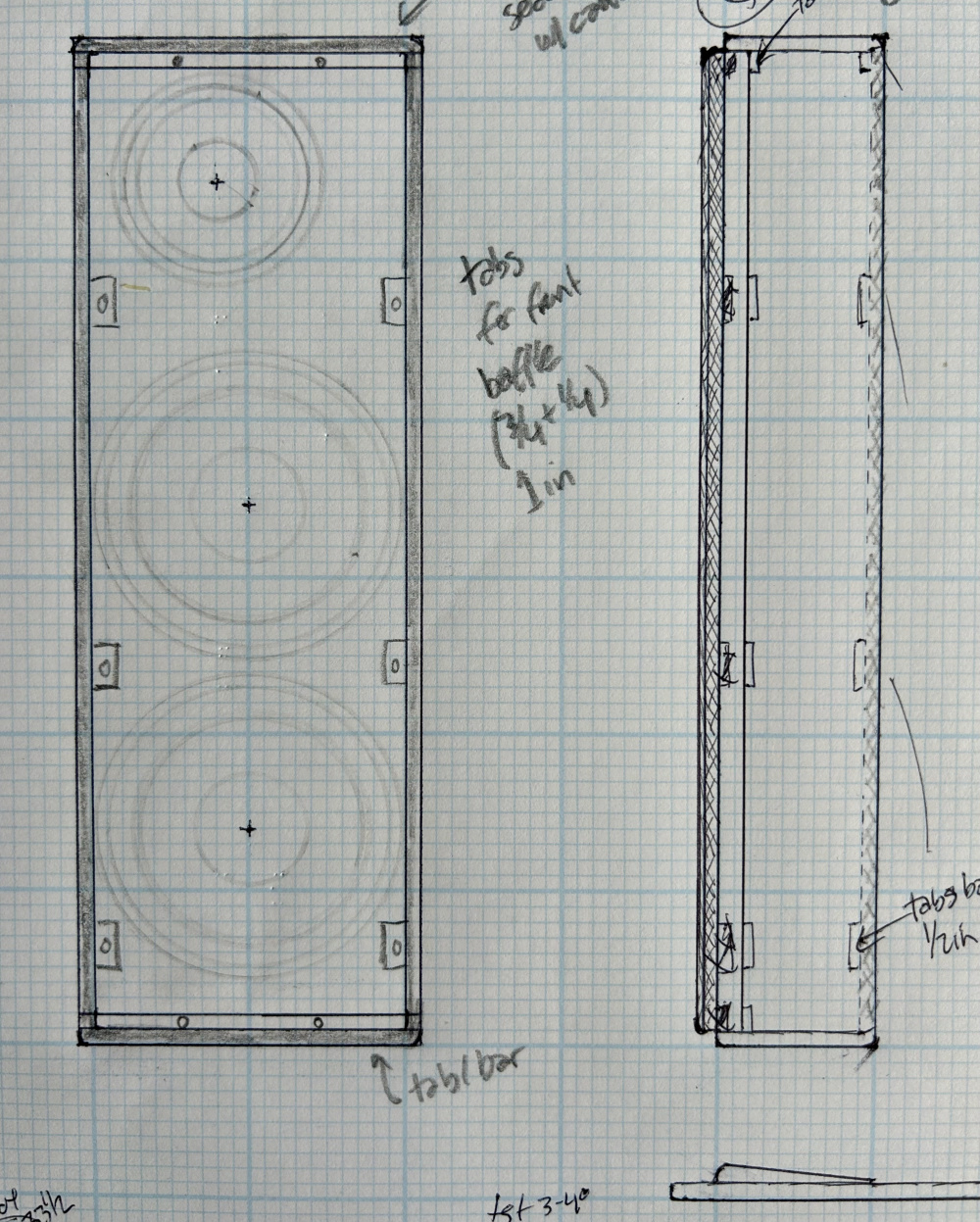

My next project I'm considering revisiting another open back / baffle project. I'd be building an internal frame using ¾ baltic birch ply attached to the baffle (also ply) as the internal bracing, and I would like to then finish with ⅜ in. solid wood extending about ¾ in. to the front and back of the internal frame for front and back grill insets, possibly using a nice walnut.

My question is, will glueing the solid wood to the internal plywood frame cause issues over time? I.e. being less stable than ply, would the solid wood tend to split / separate over time? Small leakage is not an issue here with an open baffle project as would be with a box. I'm purely concerned about appearance and durability. I don't want to do a veneer as I'm wanting a picture framed look.

Comments

I don't see a problem as your frame is not strong enough to resist the solid baffle wood movement except for the top and bottom wood strips. Look at how people attach table tops to bases for ideas. I would be more concerned about the box resonance, but that's me.

Total movement from full shrink in winter to full swell in humid summer is a % of the total width of the glue joint/board. So the narrower the section the less overall movement that joint will see. Below a certain amound the glue should be able to handle. General consensus I've heard is 8" wide or less gives the best chances for no issues.

This also depends on when you are constructing it. Idealy you would do the glue up at the middle of the average humidity swing so full swell to full shrink is only half way out from static rest compared to if you were to build it in the middle of winter or summer.

John,

For clarification: The baffle and the internal frame (glued as one piece) would be baltic birch ply, surrounded by a solid wood 'frame'. With a solid baffle, probably 4 to 5 in. depth for sides, top, and bottom internal frame and no back I'd expect it to be fairly solid. I can always put in a few side-to-side dowel braces just in case- thx.

Thx for comments and suggestions. I'm thinking the solid wood outside frame is purely cosmetic. The internal frame / baffle structure is all ply and should be fine. I'm just concerned if the ⅜ walnut stays put when glued to the ply construction. If the solid wood joint to itself in the corners moves a bit- no structural issues.

Maybe I’d be better off using a rubber caulk (vs. wood glue) and some dowel plugs at the ends of the boards to ‘attach ’ the solid wood outside frame to the ply construction.

Thoughts ?

So you are laminating 3/8 walnut to BB? That would be a no go for me. I would expect splitting of the walnut

Thx, good to know.

Heads me down the route of top and bottom wood caps over a socked speaker - as per Vandersteen.

I brought a speaker to Grinnell once that had edge glued 3/4" walnut scraps glued to 1/2" MDF. It was going to be a nod to the Sonus Faber look. As you can imagine, the walnut shrunk up and split as the humidity dropped. You could hear the wood snap across the house.

Even if not "structural" it is still a joint (one thing glued to another). Everything I said still applies. If the walnut shrinks too much while the plywood doesn't, it could crack the walnut. However if the width across the grain is small enough the total amount of shrinkage could be small enough the glue is able to deform to comply before the wood splits.