Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Who's Online (0)

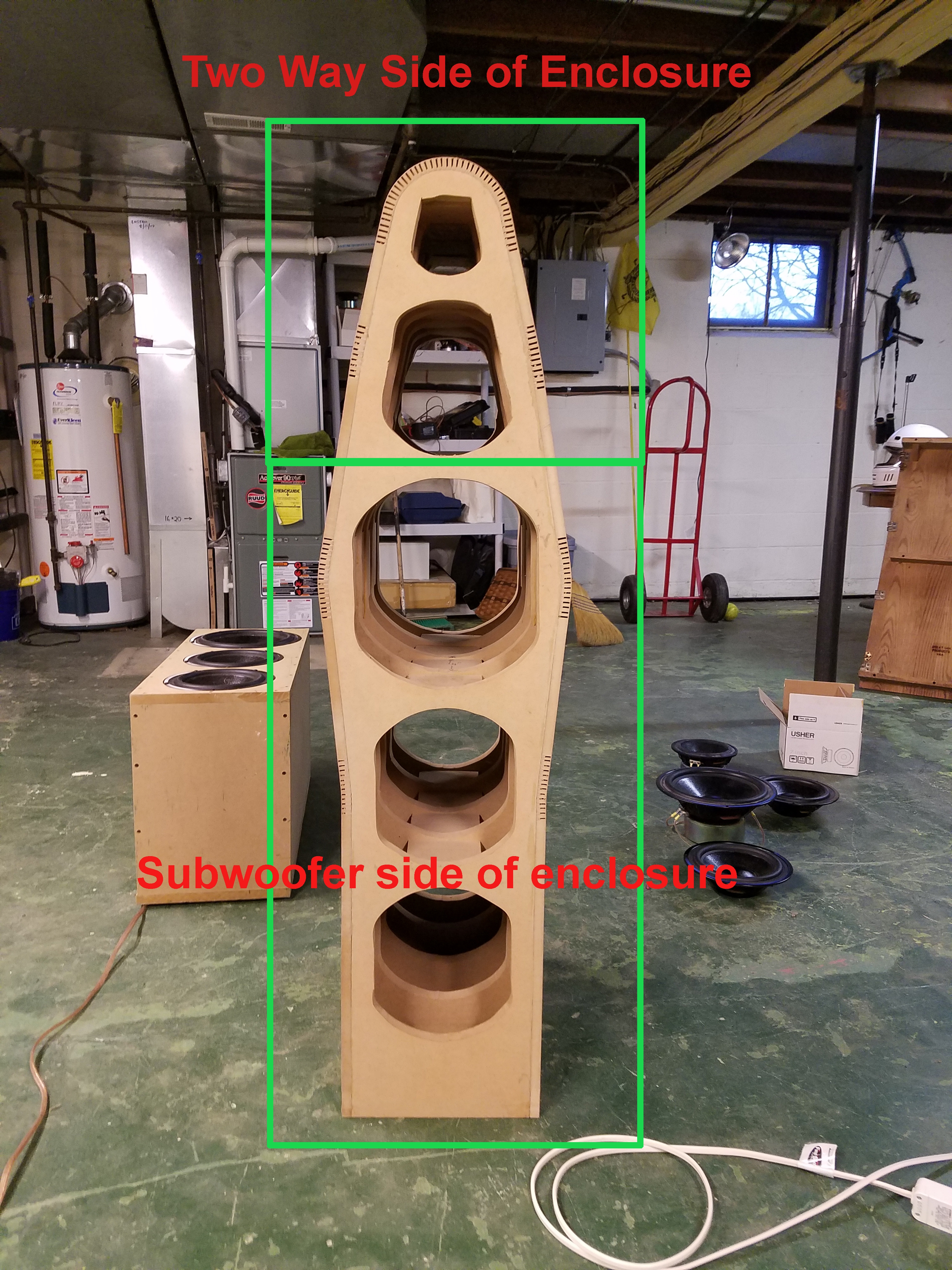

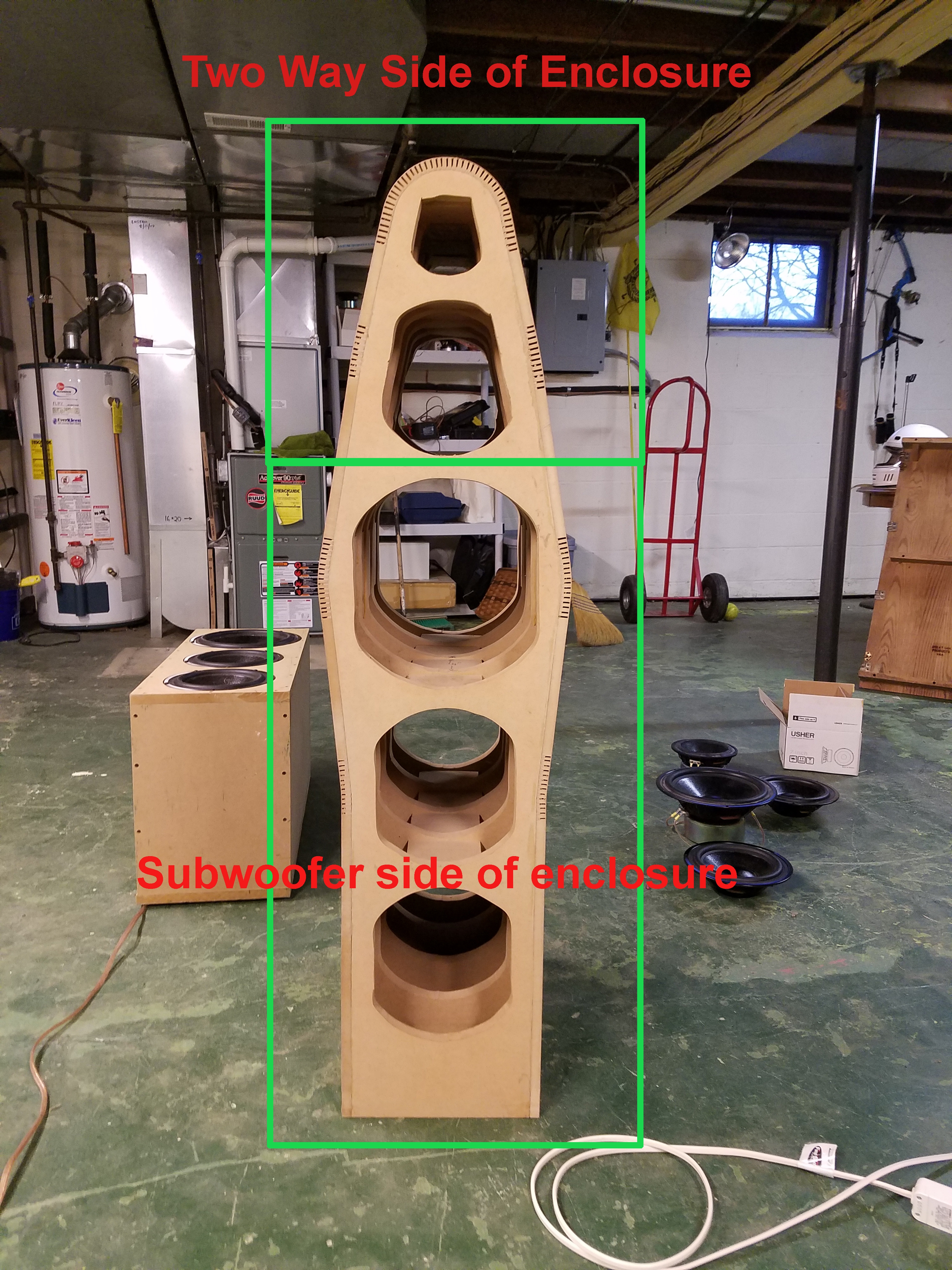

Passive radiator subwoofer and two way in one enclosure

This is my current project.

I picked up some passive radiators and a DVC driver that matched them. I did some initial testing in a test box to see how the radiators worked with the driver. Some of my findings are here.

So as i kept looking at these radiators and drivers and the shape they made. I thought this would make a good tall speaker.

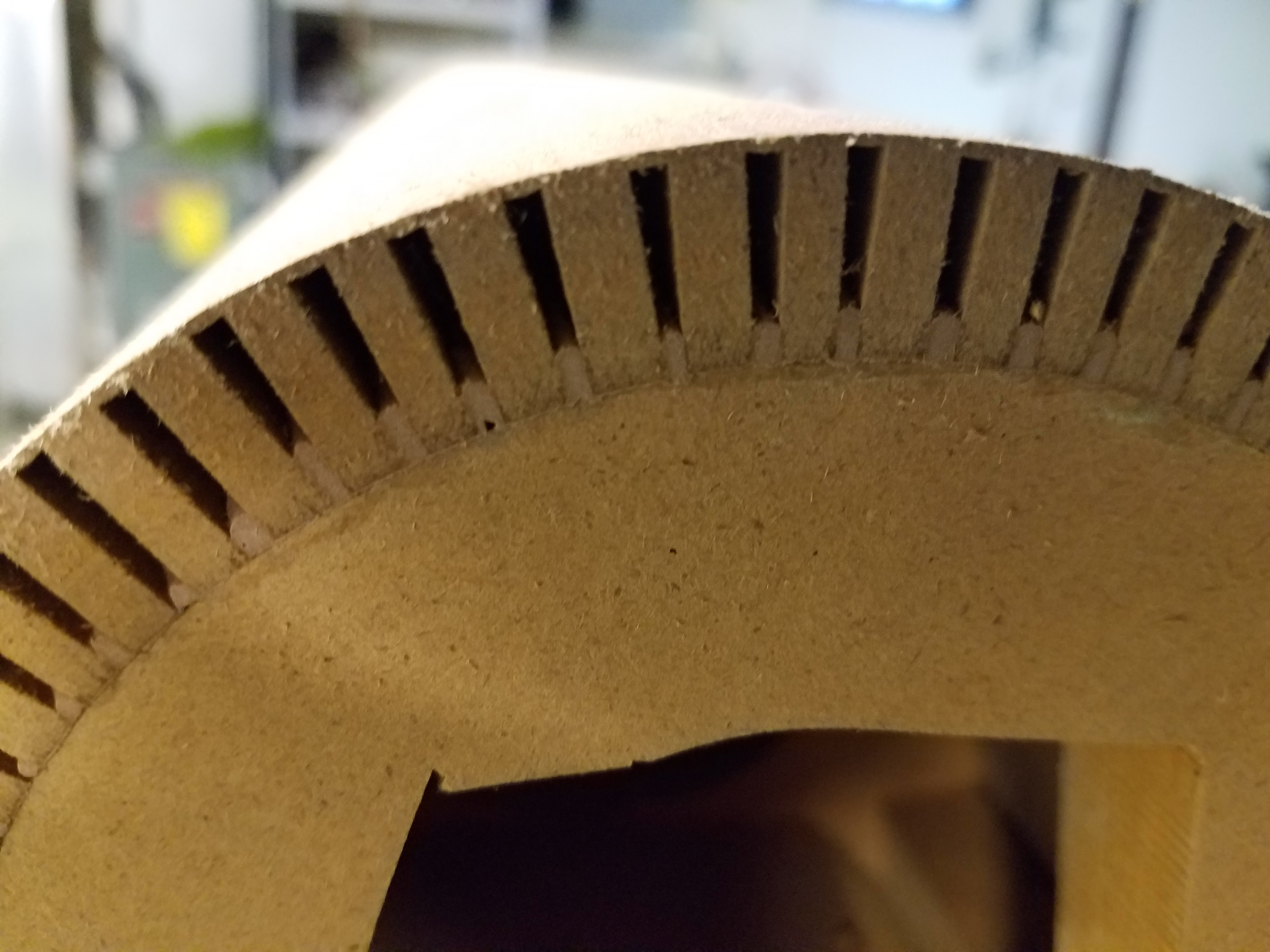

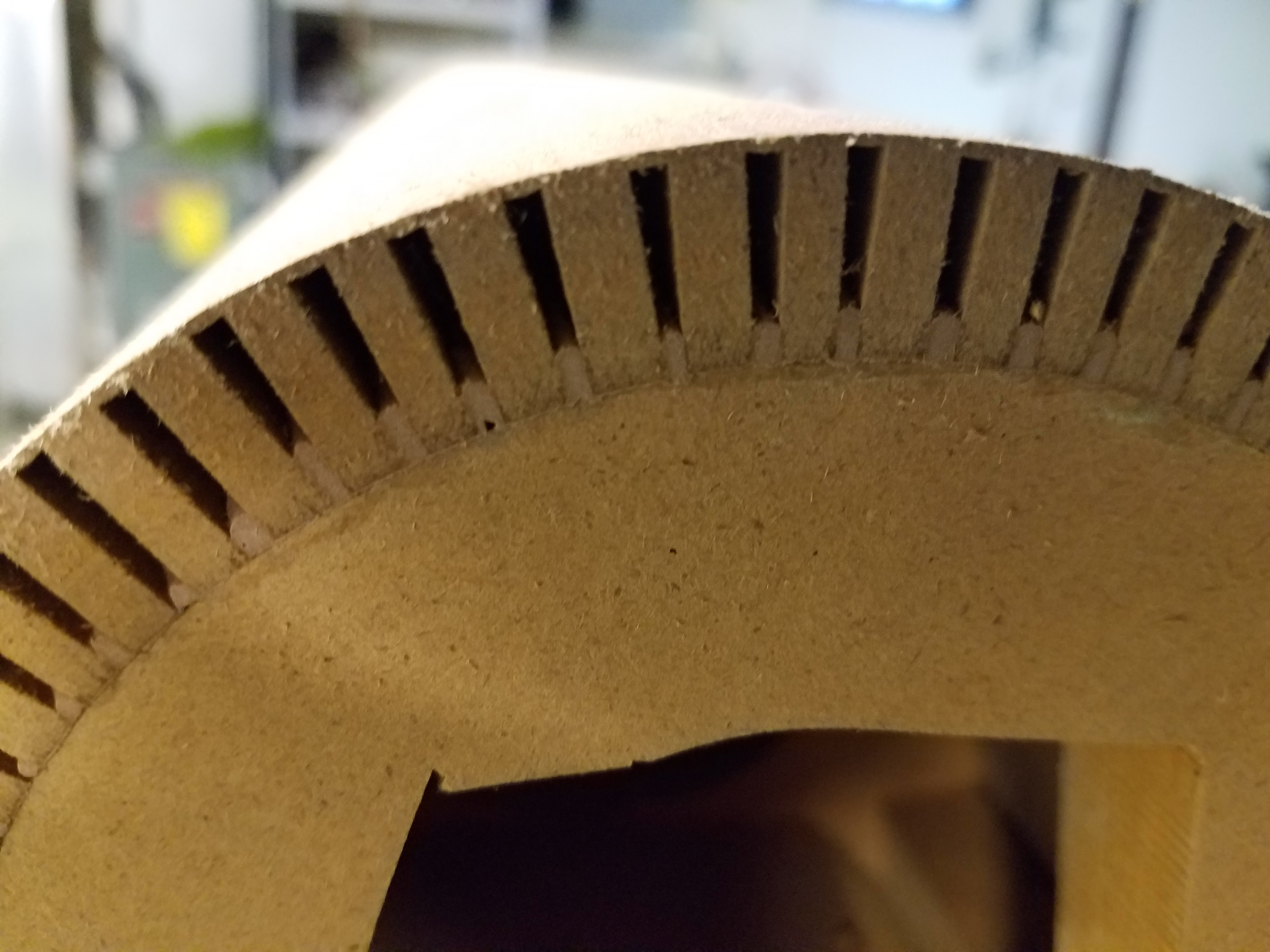

I remembered seeing someone doing kerf cuts to bend sheets of wood so i wondered if MDF would be a good candidate for it. It ended up working really well! I placed kerf cuts at the areas that needed to bend. The baffle will be hardwood of some kind. I will cover the MDF with a wood veneer or paint it.

Right now the plan is to use a plate amplifier to power the DVC driver for subwoofer. Then i need to come up with a tweeter and about a 7" driver for the two way side of it.

This box kind of came before the two way drivers. So we will see what i can find that will work well in this volume. If anyone has a two way design using about a 7" driver and tweeter let me know.

Thanks for reading!

Chad

I picked up some passive radiators and a DVC driver that matched them. I did some initial testing in a test box to see how the radiators worked with the driver. Some of my findings are here.

So as i kept looking at these radiators and drivers and the shape they made. I thought this would make a good tall speaker.

I remembered seeing someone doing kerf cuts to bend sheets of wood so i wondered if MDF would be a good candidate for it. It ended up working really well! I placed kerf cuts at the areas that needed to bend. The baffle will be hardwood of some kind. I will cover the MDF with a wood veneer or paint it.

Right now the plan is to use a plate amplifier to power the DVC driver for subwoofer. Then i need to come up with a tweeter and about a 7" driver for the two way side of it.

This box kind of came before the two way drivers. So we will see what i can find that will work well in this volume. If anyone has a two way design using about a 7" driver and tweeter let me know.

Thanks for reading!

Chad

Comments

Kerfing Plywood Jintani Speaker Project

I just did my first kerf project with 18mm Baltic Birch ply. Used Gorilla glue to fill the kerfs, and had some problems filling all the voids, but resulted in a very strong bend.

You've got to play around with some scraps to figure out spacing and depth.

If the depth is not enough, bending is really difficult - if the depth is too deep, you will get cracking or splitting.

I found that about 1 1/2 layers of Baltic Birch worked well for me. One nice aspect is that once you have your jig set up,

the cuts can go very quickly.You will need some strap clamps to make the bends on your production box.

Hope this helps.

In any case, it doesn't look like Chad did any calc to determine the bend radius, just closely spaced the cuts so he has more than he needs, and the bend radius is determined by the board it's wrapped around. This may actually have some benefit, as cuts with a wide spacing may make for a less curvy bend with points where the kerf cuts are.

Thanks dB!

When I started to look at kerfing, every example showed bends where the inner part of the cuts all touched.

I felt that the bend would be plenty strong if filled with Gorilla Glue even if the inner parts were not touching,

and allowing for "extra" bending capability gave a little more leeway when gluing up the bend.

That looks like a correct assumption.

Once i get Soundeasy i will get some real measurements.