Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Please review the site Rules, Terms of Service, and Privacy Policy at your convenience. Rules, TOS, Privacy

Get familiar with the reaction system: Introducing the Reaction System

Comments

Interesting - never seen one before.

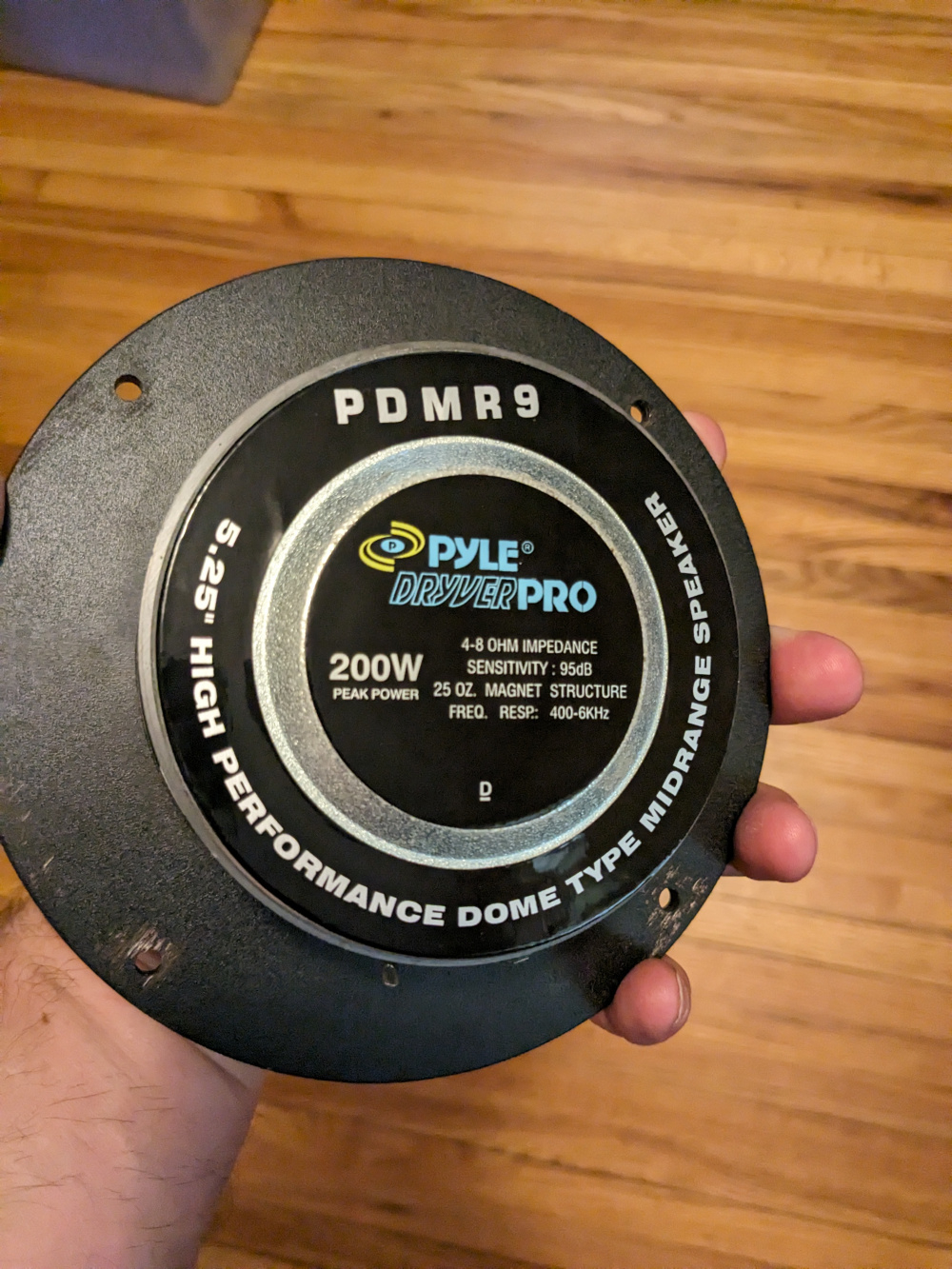

https://www.pyleaudio.com/sku/PDMR9

Can you run some FR sweeps on it?

I've read about it or seen images, and wondered about it too. It's bigger than I thought seeing you hold it.

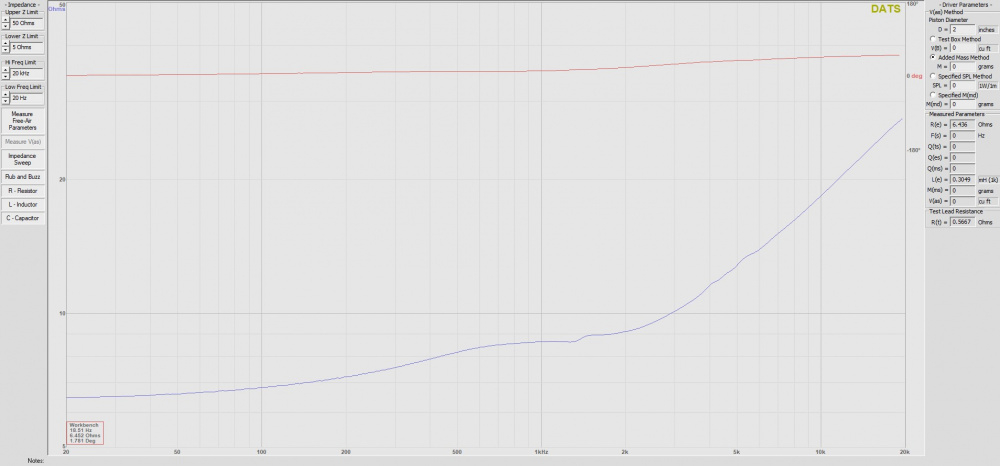

The impedance looks kinda weird...

InDIYana Event Website

It could be a trick of the camera.. shadows and the angle holding the driver, but the diaphragm looks off-center. That can really mess with the impedance sweep. Wonder if there are screw heads under that felt ring to take it apart and re-orient the diaphragm better. Depending on the design, might be able to run sweeps while nudging the diaphragm around to match a pair up better.

That felt is the surround.

InDIYana Event Website

The faceplate looks roughly similar in design style to the bullet tweeters where they put an embossed sticker ring surrounding where the horn begins. The area just inside the dark black felt(ish) ring has the same texture as the rest of the faceplate so I think it is part of the faceplate for mild horn loading. I can also see where a different surround material is adhered around the dome itself.

Looks like no real back cup on it, though I suppose there could be some hollowed out space inside the pole piece. Wonder how it stacks up to the new GRS 2" dome.

I can tell from the photo that there’s no copper in the motor 😛

Here is another angle. The felt probably does cover the screws that hold the two parts together. The face plate is cast aluminum and the dome has a rubber surround.

Lol playing off this thread I see?

https://diy.midwestaudio.club/discussion/2324/do-rs-aluminum-midbasses-actually-have-shorting-rings#latest

I'll try and get some measurements, but I'm not holding my breath based on what I read at diyaudio: I've only tested one Pyle driver myself (Pyle PDMR9) but the distortion was so bad that it was basically unusable - there was a tiny range between 1kHz and 3kHz where the non-linear distortion was borderline acceptable. The flange is so huge that to maintain a reasonable CTC distance with the tweeter you'd want to cross no higher than 2kHz so basically you end up with a driver that only works from 1-2kHz, useless! After seeing my distortion measurements I had to double check that the coil wasn't rubbing - nope, just an extremely poorly designed motor system. Pyle claim "400Hz to 6kHz", yet anything under 1kHz at any acceptable volume (>80dB @ 1meter) drove it into bulk distortion. As such, I don't hold high hopes for any of their other dome drivers. Too bad, because the build quality actually is quite nice - big magnet, heavy cast face plate etc. Too bad they put zero effort into the actual acoustic engineering.

They are no longer available from what I can tell and that might be a good thing . . .

I agree. Too much faceplate, not enough dome.

Sehlin Sound Solutions

Well then they couldn't call it a "5.25" High performance Dome type midrange speaker"

Yeesh that is quite the gap between the face plate and dome.

I miss when Pyle actually had good products.