Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Speaker Connections Question

Hello from Oz and Happy New Year to all

I've always used Dayton or similar binding posts on my speakers, but would be interested to hear your views on other methods.

In my COVID lockdown web surfing, I found a site and some videos which extolled the idea of a hollow copper tube into which you insert the leads from the amp and into the speaker. This supposedly 'takes a big chunk of metal out of the signal path' and makes for clearer sound. A/B testing on the video says there's a noticeable difference. That may or may not be true, of course I don't know.

However, if it is true - that removing the binding posts or cup connectors from the system is desirable - why not just connect or solder the leads together and save the rather considerable damage to the wallet? Would the direct connection fry something in the crossover?

Thanks

Geoff

Comments

Personally, I like a big chunk of metal between my amp and the speakers.

You can do that A/B comparison for yourself rather easily. Take your terminal cup and just take the binding post out and run a wire straight through, if you worry about the tiny tiny hole left over just stuff some batting in with a toothpick, or some hot glue that can easily be broken away from the plastic.

Now you have a wire directly from the crossover out to your amp, and you can A/B test the different of adding a big chunk of metal in the middle, specifically the binding post that you just removed. Make sure you have a friend randomly add or remove the block so you don't know which is which. I'll buy you a beer if you can reliably tell the difference.

Anyway, if you want to try something different than a binding post, give Speakon connectors a try. They're a bit of a pain to terminate but are a locking quick and easy connection without ever worry about leads touching if they are pulled from the speaker. Best of all - they're cheap as a standard connector in pro audio so manufactured in high volumes.

Was this a Dannie Richie or GR Research video? Meh....

Just ignore if it is.

InDIYana Event Website

Electra Cable tube connectors?

https://www.gr-research.com/store/p44/Electra_Cable_Tube_Connectors.html

Not the worst thing I've seen, but looks cheap, is cheap, and costs too much. It assumes that your wire is butted up against the end of the connector solidly, which is unlikely especially after you disconnect and reconnect a couple times. The crimp is at the end of the plug, same as any banana connector so the performance will be similar at best. If anything the connection will be worse as you don't have much spring tension against the barrel.

At $20 a set I'd say you could give it a try as that would be comparable to a pair of $5 terminal cups and a set of cheap banana plugs. Not a big loss if you don't like them. At $50 a set you're a sucker. I can't see them performing any better than a cheap banana plug, not that the connector has any effect on the result in standard home installations when terminated properly.

And they wear out, according to some testimonials.

InDIYana Event Website

I do like speakon connectors.

And there was some test that used a hanger instead of speaker cable somewhere, right?

If I remember correctly, was not detected in abx testing.

You could easily test as dcibel mentioned and even perhaps add another step by adding a brass screw to your link.

Terminal cup - - wire--screw--wire--speaker

If you can hear the difference with the added screw, you can decide to replace your bananas and terminal cups.

Arent most of these glowing reviews done by the same people that freeze speaker cables, have latters for their speaker cables and can't sleep at night worring that their cables are plugged in backwards?

If you are ever really concerned that your connections are not good enough look to the electronic testing and development industry where banana plugs and BNC connectors rule the world.

Bnc connectors can handle 316watts at 1 ghz. With almost no measurable loss. (.02db at 3ghz) Banana plugs are rated for 30A at 60V, with extremly low signal loss. Want a low mass connector just order a pannel mount banana receptical.

A good electrical connection is not as hard as they make it seem...

Thank you all for your comments: just to clarify, I wasn't so much wondering about whether my connections are OK, more whether other ideas are worth considering.

The tube connectors are indeed the GR product, and due to the $A relative to the $US, I wouldn't consider them as they would be about $80 plus post! Directly connecting the wires wouldn't cost anything except swear word output when I wanted to move the speakers around, which isn't often.

Cheers

Geoff

Yeah, don't waste your time with those silly gimmick tubes. If you want to try something different than a binding post, speakons are definitely available locally in Australia, quick search suggests Jaycar, Element 14, and some pre-made cables can be purchased from a place called Cable Chick.

http://www.farnell.com/datasheets/1731545.pdf

Thanks, I'll check them out

Geoff

Indeed it was...

Geoff

I stumbled on some of Dannie's videos earlier this year. Once I heard him blathering on about those tube connectors a few times I stopped watching. They are obviously a high-profit item. I'll bet they only cost him a buck/pair from China. As "audio jewelry" goes, these just look cheap. There are a lot better places to spend the $60 these things would cost you.

That got me thinking what would be your short list to buy for $60-$100? Can't be drivers or parts like caps and inductors.

My list would be some nice banana plugs, speaker stands, maybe some cable to make interconnects. I'd like to remake my speaker rotating platform for off axis measurements.

Maybe some nice veneer - because you know a fancy looking speaker always sounds better, right?

Oh - I do like your speaker stand idea. Mine are medium-duty at best. I really need to build a nice pair of stout stands that I could fill with sand.

I'm considering my 5th set of stands. I makes it easier to swap out speakers

I would like some nice outriggers. Haven't used them yet, but elegant outriggers not only look good but provide much needed stability to talk skinny speakers. Though I suspect the budget may not be enough...

You can buy aluminum stock and cut, sand, polish and tap threads for some really nice outriggers for that kind of money Ani.

I used painted steel bar stock and these bumpers. I think I have some some left if you want them.

https://www.mcmaster.com/9309K19/

I have not yet worked with aluminum - either for outriggers or amp boxes. what thickness works? and how fast / slow do you go? and what tools and what speeds? circular saw / table saw / router - drill - but forstner bit? spade? regular / step drill bits? dry or wet cut - that might limit tools

I have seen alu being cut using cnc, but this guy didn't really knew what he was doing, and most people at the workshop i used to go to cut most wood - so didn't find anyone who could show me the correct bit/speed/depth pass.

also, whats a good place to alu stock?

I was a production machinist in a past life but didn't have anything to do with choosing the tools or specifying the machine speeds and feeds. I have done a lot of work on aluminum chassis for DIY electronics and some tools and materials machine better than others. I looked at Google and found this guide for machining aluminum.

https://makeitfrommetal.com/how-to-machine-aluminum-all-you-need-to-know/

Ron

Ani you can buy aluminum remnants on eBay, I have purchased quite a few pieces from a seller called stoner tools. Carbide router bits work fine, but you have to take light cuts, and they make circular saws and chop saws for dry cutting metal, but I have used a radial arm saw with a carbide blade and made multiple light passes, it took me about 20 passes to cut the angles on the pointy speaker outriggers. Lubrication is aways a plus in order to minimize the aluminum sticking to the cutting edge, but let's face it, sometimes it's just not a possibility to make a mess.

For making outriggers some bar stock should work well. Mcmaster carr has 3/8 x 1 1/2 x6ft for $23.55. https://www.mcmaster.com/aluminum/shape~sheet-and-bar/thickness~3-8/width~1-1-2/

Wooden or 3d printed spikes would look nice.

As far as machining most woodworking tools will work perfectly on that thickness. A simple hacksaw and a good file could also get a lot done. Hand sanding will get you a really nice finish as well and it can be buffed out from there.

thanks for the details. Is 3/8 sufficient to hold up heavy towers? Also, finishing options, assuming that anodizing is out of the picture

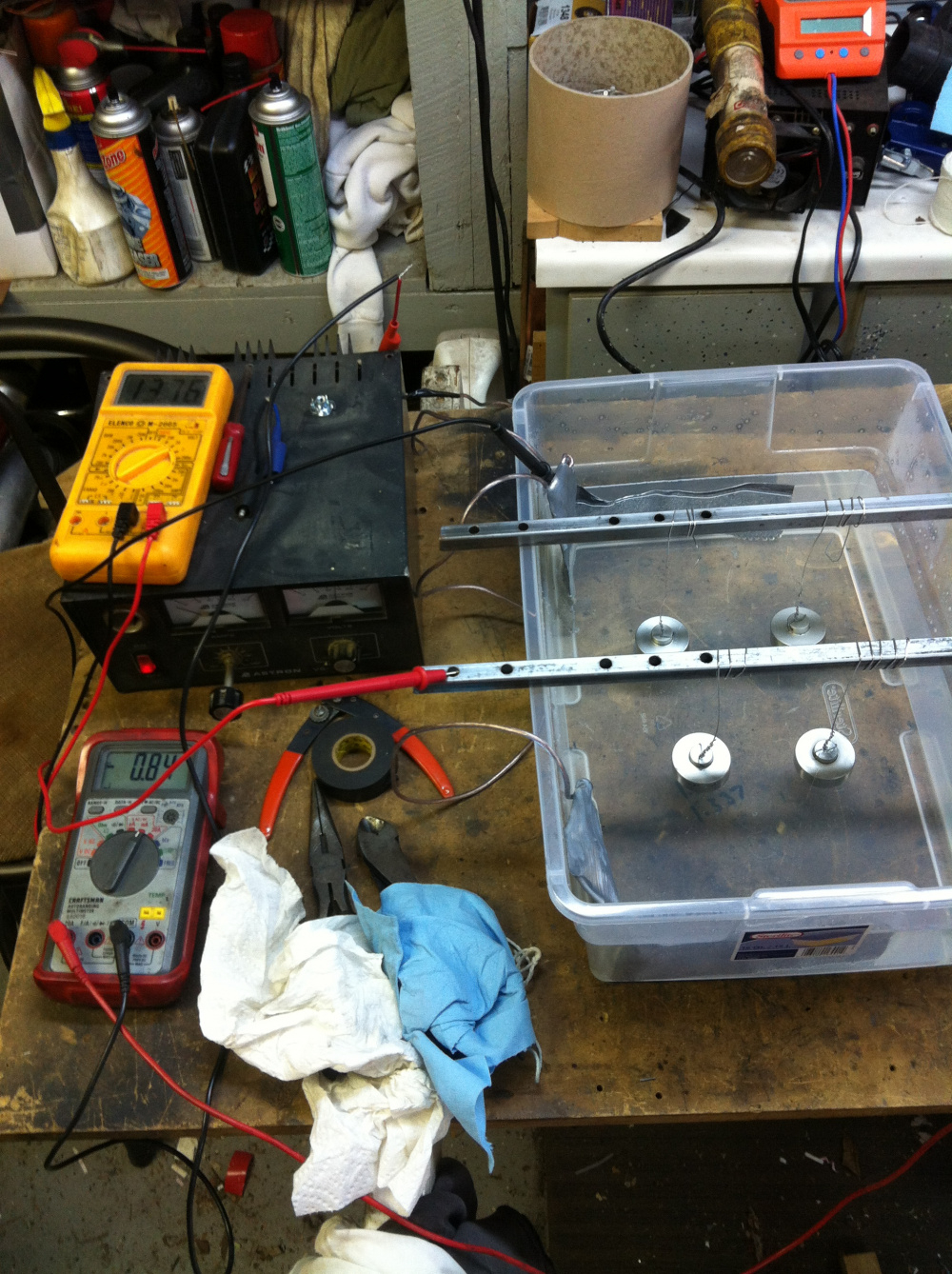

Anodizing isn't out of the question. It can be done at home. I did the phase plugs on my RSR build.

OMG, dude, that's too effing cool!

Ani, it should work for most towers as long as they don't go out too far. Most of what I have seen only goes out a few inches.

Anodized parts look great. Even a simple clear coat will look good.

Are those the phase plugs on rs drivers? How did you get them off? Did you/could you do some kind of write-up on this?

Turn driver over and support it somehow. Insert brass pin punch into rear of driver. Seat firmly against backside of phase plug. hit punch with hammer. Catch phase plug. First one I did at room temp took a harder whack than the one I did at SoDak February garage temp. That one drove out almost scary easy.

I did not reinstall so can't help you there, I did glue a copper washer on the pole piece though, as the phase plug serves dual purpose as a shorting ring and an extended pole piece. I glued a soft poly dustcap on the driver, but was less than satisfied with the results so the experiment went nowhere. I maintained more or less the inductance rise and distortion of the phase plug arrangement, but I was hoping to fix the cone breakup issues with the poly dustcap.

I rolled a piece of wax paper and inserted over the pole piece to mask things off so the glue wouldn't fuck up the voice coil.