Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Who's Online (0)

Saving Private Selenium

On a stage long long ago there used to live a hella loud bass rig. It pressurized a room like no other, conveying it masters every input with crowd pleasing waves of bass guitar awesomeness. Then it stopped. Tucked away in a shed for years it waited for a day to return to it's once glory.

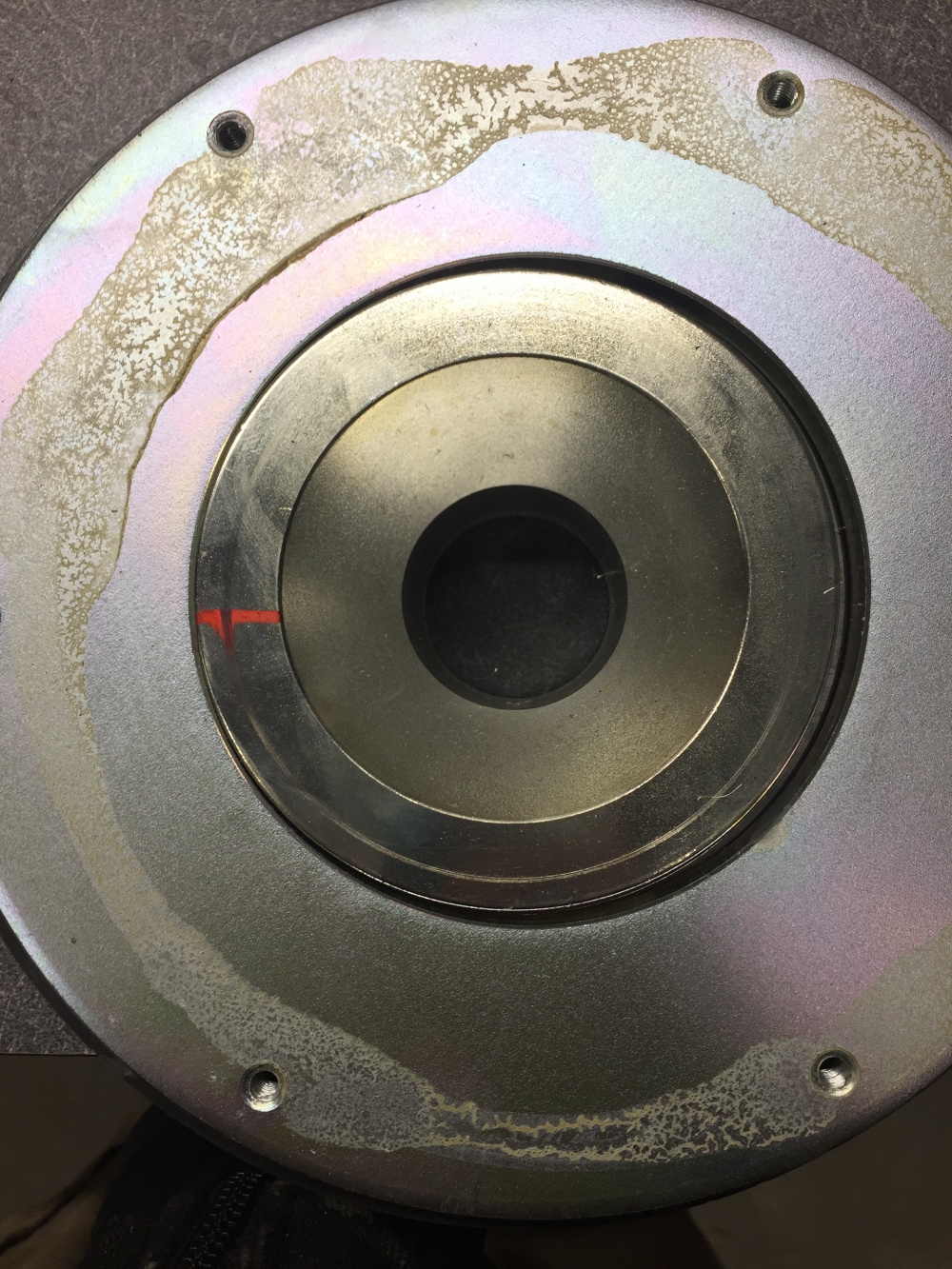

Well that day happened last January. Upon getting it here, I removed the grill to inspect the 18" unit that once supplied the low end of a biamped bass rig. I was a bit nervous as the cab was in pretty bad shape at the bottom, as if it had gotten wet several times. As I pushed on the cone, nothing. Locked up tight. At first I assumed it had corroded itself. I pushed harder....and harder....pop, it moved. Unfortunately it stayed in. Not good.

Disassembly reveled what had happened. Apparently after its last gig and now it took a drop that spelled it's demise.

Comments

I had a JBL 15” guitar speaker like that, I think it was an E140 perhaps. Rather common failure. Cost of saving it was about the same as purchasing a new driver.

Had an 18" B&C do the same thing after a drunk driver ran a red light and hit our trailer. Flipped it onto it's side, throwing gear all over the place. The corner of one 2x18 was poking out of the side when the wrecker flipped the trailer back onto it's wheels. Our bass player who owned the subs replaced the driver, but there were cracked joints in the box, so it buzzed a bit at certain frequencies.

It was easily more cost effective to buy a new one, but I can't just throw a bitchin unit like this in the trash. So off I went to a local reconer and freind to see about recone parts. This model of course wasn't available, so I asked him to source parts that would work. I had never reconed a speaker before and wanted to do it just for doings sake. Honestly didn't care if it was exactly like it was before.

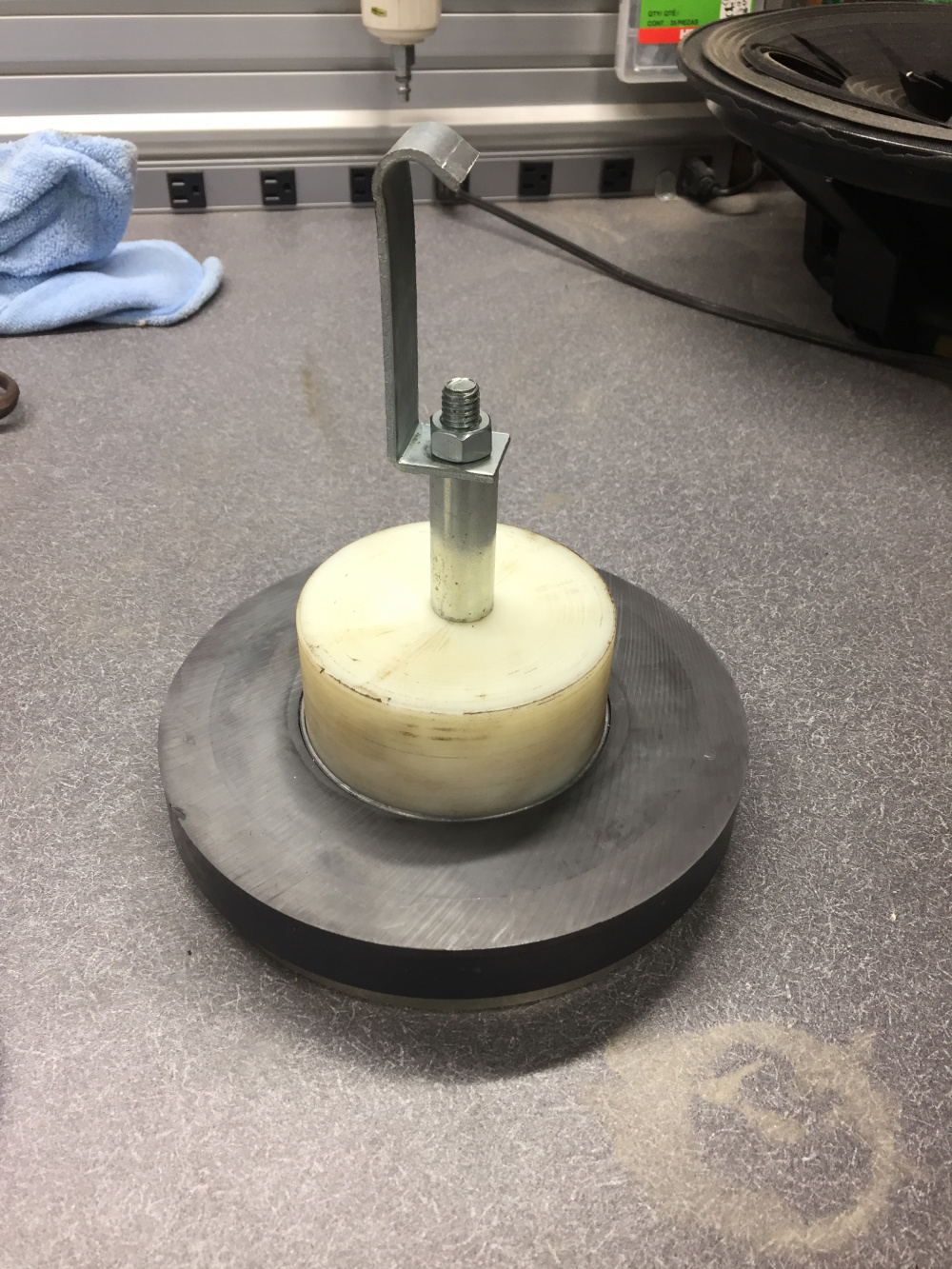

First up was fixing the top plate. I used the basket screws to jack it up off the magnet. Then used flat tip screwdrivers to pry it off. MF! A plan was devised to make a spacer that would center up the top plate on the pole piece. I enlisted a buddy and his lathe to turn the jig from UHMW round stock. We drilled a hole to use a slide hammer to remove it, if it decided not to cooperate.

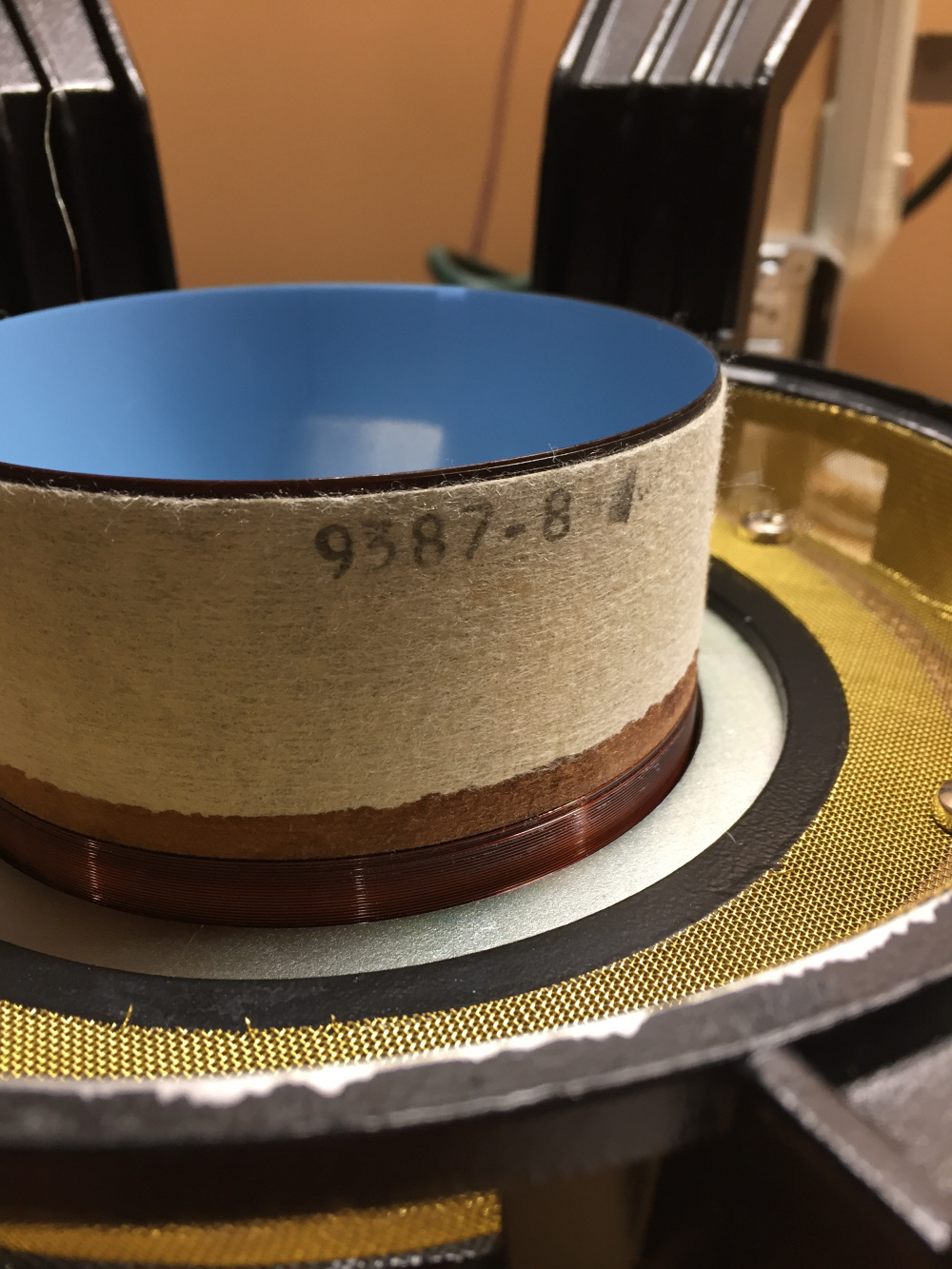

I used super glue to attach the plate. The jig did its job perfectly, with minor slide hammering for removal. Next up was parts. The guy came up with what looked like feasible stuff to put in it. Unfortunately an important measurement that he asked for, I over looked and didn't give him,.... he order a cone and VC that didn't fit this speaker. Me personally, he being a reputable reconer, doing this for a living for the better part of his life, should have never ordered these things without the cone depth measurement. Then he proceeded to tell me no one offered a replacement that would fit. 🤨 After a few minutes of research and online company had stuff for a similar Selenium driver that would fit.

I gave him the info, he magically ordered the parts. Then the shit hit the fan when he tried to charge me for the new parts. He blames me for not giving him the measurement, I called BS, you should have never ordered the first stuff without it...mr professional! Anyway I gave him the original stuff and took the correct stuff, we are no longer friends. I think he tried to blow me off because he didn't want to eat the cost of the wrong junk. Such is life.

It sounds like you may be a more competent speaker rebuilder than the "professional". Great job getting the top plate lined up and glued down again. I hope that woofer sounds close to what you remember once you have it all buttoned up.

Crappy turn of events no doubt.

After finding the rest of the junk needed, I started figuring out how to get all the parts to play nice. I ordered a glue kit and got the shims to center the VC. Keeping the VC height was the most difficult issue, but not real bad. Without all the fancy measurement stuff there's no telling how centered in the magnetic gap it ended up.

I started the glue up with the bottom spider, then once that was set the top one went on. That was another issue, the first set of spiders he got me had a 3" opening, said it's not uncommon to have to cut it open to fit. 🤨 Then he found a set of right ones. 🤦🏻♂️ .... unfortunately those had the wrong height spacing and wouldn't work. So I ordered another one to use with one of those, plus a spacer.

Awesome! Careful you might find that building woofers is kinda fun..

I like seeing your work with recentering the pole to plate. I have a pair of heavy sub motors that got dropped in shipping and knocked the plates loose. This might be the motivation I need to fix them.

Thanks👍🏻 Unfortunately I gave my centering tool to the reconer guy in case he ever came across a need for it. Figured I'd never need it again....😒

I'm sure you'll be able to pull it off for your units, good luck🤘🏼

Next up was cone fitting. The cone/surround assy. I found was very different from the OE. All I could find at the time was for a subwoofer. My original speaker was an extended low end application, but still had decent upper end response. It fit, so that's what went in. I always thought the aluminum dust cap was neato on the JBL stuff, so I threw one of those on there. Side note, never realized how thin those caps were.

As you can see by the T/S parameters, this driver likes a big ol' box. To utilize it at home this isn't an option. I'm using it as a practice rig, so very little sound volume is needed. With that in mind, I just built a quick H frame to see if that would suffice. It actually performed perfect for my needs, so I plan to make a nicer looking enclosure. It is a bit overkill, but I can't just throw it away or on a shelf never to be used again, right? There's enough EQ on my amp to make it sound good enough to jam along to some Maiden or write stuff, so what the hell🤘