Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

4thtry's InDIYana 2023 theme build

Thought I'd add mine to the mix. Build thread link below. I brought these to Iowa 2021. They use Isobarik SD215A-88 woofs and golden RST28F's, crossed at 900Hz, 8th order (tweeter yoga to the max!). Backs are removable, so I have full access to all drivers and xover parts.

I re-painted the cabs since Iowa (they looked too bright!). I also re-tuned the port to eliminate the pipe sticking out the back. Next project will be re-tweaking the xovers for better sonics. I'll snap a couple photos showing the new paint job and ports and post them as soon as I get a chance.

Tagged:

Comments

Build thread link: https://diy.midwestaudio.club/discussion/1513/the-zonkers-an-isobarik-8-two-way/p1

Combo speaker paint job and snowblower repair pics. Snowblower is now running good again after rebuilding the carburator for the 2nd time. Tecumseh carburator rebuild kits are much cheaper than new snowblowers ($15 verses $1500-2000+ ouch!). I purchased this Simplicity new in 1987. It has worked well most years except that the carburator keeps gumming up over the summer. I run it dry at the end of each season, but it still keeps gumming up.

The new speaker paint job is Rustoleum metalic oil rubbed bronze, which seems to blend much better with the dark wood grain shelving panels. Port no longer sticks out the back. I added an internal port coupler, so the tuning is the same.

I had to switch to non-ethonol gas because the seals in my Tecumseh carb kept swelling and leaking on my gocart. It's sold as REC fuel at select gas stations.

Sound like a good idea. For the past 2 or 3 years, I had to shut the gas value off after snowblowing the driveway, otherwise gas would leak out all over the garage floor. I always use the cheaper gas, which contains 10% ethonol (87 octane). I just filled my 2.5 gallon container with the cheap ethonol crap, so I'll dump that in my car and refill it with the good stuff.

That snowblower is an oldie, but a goodie. Looks fairly similar to my Craftsman, but I think yours is built better. I headed the advice of my mechanic son and been running only premium in the lawn mower & snow blower for the past 4 or 5 years. Add a little Stabil before putting it to bed and it starts easier now after the long sleep. I know how fickle some carbs can be (my Yamaha 1100!) and rebuilding them in an unheated garage in the winter doesn't sound like much fun.

Premium isn't any better for small engines. They're not optimized for the higher octane and it still has ethenol in it. The Marathon I use to get REC fuel from had 89 octane, but they quit selling it. Now I get it from another place but it's 90 octane.

You can burn up small engines with high octane gasoline - be careful.

Use non-ethanol in them; regular 89 octane grade for best results.

The ethanol in the blended gas eats up the rubber float valve seats/plungers and causes all the mayhem.

Best to drain the tank and carb bowls over winter and avoid ethanol gas altogether for small engine use.

Absoutely incorrect statement.

Octane refers to detonation resistance. Using higher octane than the engine requires will not hurt it, but also won't create any more power, which is another myth.

100% fact!

It just burns through your money faster.

Around here 91 octane is what I call Premium. It's the the only grade I can find close by without Ethanol. I'm not running 93 - not even sure where to find it on our side of town.

I won't waste time arguing as I have done this with a 2 cycle engine in the past.

After reading the manual it specifically stated not to run higher octane than recommended for this very reason.

Have a nice day.

Post a picture of the page in your manual that says that. I'd like to see it.

Thanks

Weed eater from 20 years ago - no longer have either the manual or weed eater.

I wish I had kept the manual for just this discussion.

Not to throw in a wrench, but I just recently bought a Stihl chain saw and it states to use premium. The dealer even suggested pumping a bit into the car first to clean out the hose (if previous car used regular) before pumping gas into my gas can for use with the chainsaw. (maybe he is a part owner of the gas station - ha)

I liked this thread when it was about speakers.

Nah, this is a real thing. When having some finicky motocross bikes that ran ok on 93, but pinged like a can of rocks on anything less, we always ran the first ~gallon into the truck before filling the gas cans.

Craig is correct. Some off us have built enough engines to know better and are not mistaken in that octane is only an issue if you don't have enough. Period. Now back to speakers. Nice job Bill.

Thanks for all the tips. Here is a photo of carb parts that I replaced. I soaked the carb and all re-used parts in carb cleaner for a couple hours, blew everything out with air hose, then re-assembled with new parts. As you can see, lots of rubber seals and gaskets to get sticky or go bad in there. The paper clip did not come with the re-build kit, I made that to pull out the small rubber o-ring seal in the pic. The new seal is then press fit into position using the back end of an 11/64" drill bit. Regarding octane, I think I have a couple gas stations in my area that sell 89 octane non-ethanol. It is more expensive than the 87 octave 10% ethanol stuff that I normally use. Engine is running good with the new parts, maybe this, plus a little STA-BIL added, will keep this from happening again.

Yeah, let's can the gas can talk, guys.

Thanks, Nick. Going back to the speakers, my plan is to re-measure the tweeter alone, with xover included. And then measure the woofer alone, with xover included. Same 1 meter on axis mic position and vol setting for both measurements. When measuring the tweeter, I will run a long wire from the crossover to the other woofer/xover, located in another room with the door closed. In this way, I will be able to make an accurate measurement of the tweeter's SPL and phase alone with xover, without any interference from the woofer. I'll then do the same thing to measure the woofer alone, this time with a long wire running from the crossover to the tweeter/xover in another room. I can then overlay the two actual SPL/phase curves to see how good the actual phase tracking matches my modelled phase tracking.

I don't get it. What's the difference from just disconnecting the woofer from the x-o and shorting the woofer terminals?

I do listening test like this.

I have had problems trying to do what you are suggesting. Disconnecting the woofer from the xover would cause the protection circuitry on my KLH amplifier (100wpc) to start clicking in and out when only the tweeter and tweeter xover section was connected to the amp. I suppose I could just connect an 8 ohm dummy load in place of the woofer to keep this from happening. But then the load on the amp would not be the same, and this, in turn, could affect the measured frequency or phase response. Since I have two completed speakers, my solution will be to place the extra speaker in another room and, via a long cable, use that remote speaker to complete the load.

EDIT: On 2nd thought, the protection circuitry could not trip on a 2 way xover because disconnecting the woofer or tweeter would not cause a problem. I had this problem when trying to test driver/xover sections alone on some of my completed 3 way speakers.

You should probably not keep that amp if that's the case...and especially not use it for measuring speaker performance. Besides, proper use of 2channel measurement effectively removes any amplifier error from the measurement since the amp is within the feedback loop.

Disconnecting the woofer but leaving it's xo components in place can present quite poor impedance to an amplifier, the entire crossover branch for the woofer should be disconnected, leaving only the tweeter filter in place.

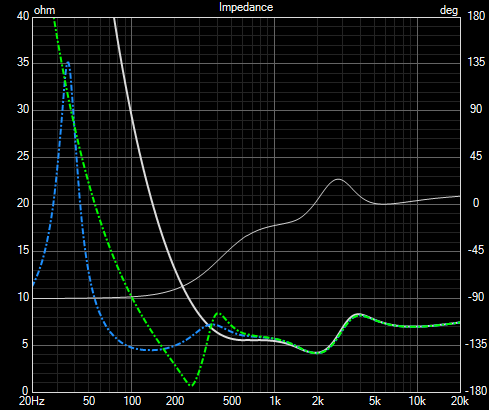

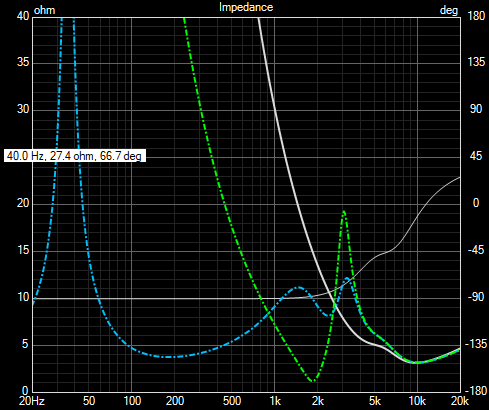

Here's impedance for a typical 3-way (blue), impedance with woofer disconnected (green), and impedance with woofer branch disconnected by removing the series inductor (white).

Same result for a 2-way, only difference is the frequencies at play.

Probably not necessary, but I replace the driver with a resistor similar to Re.

OK, so it is the inductor causing the low impedance dip on the two green curves above. That is what was tripping the protection circuit. I'll just swap an 8 ohm resistor for the woofer and I should be good to go. Thanks.

For a 2nd order filter, the inductor and cap with nothing else connected creates a resonant circuit that creates a short circuit at it's resonant frequency, shown above in the green curve. Many amps may be fine with this for a short duration of a frequency sweep, but some may not. Adding in a resistor in place of the woofer will ensure the overall impedance is kept in check.

Isobaric would fit within the rules?

I'm not sure. This concept is not mentioned specifically in the rules (unless I missed it). If excluded, I could always remove the internal woofer and try re-working the xover a bit.

It's fine.

InDIYana Event Website