Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

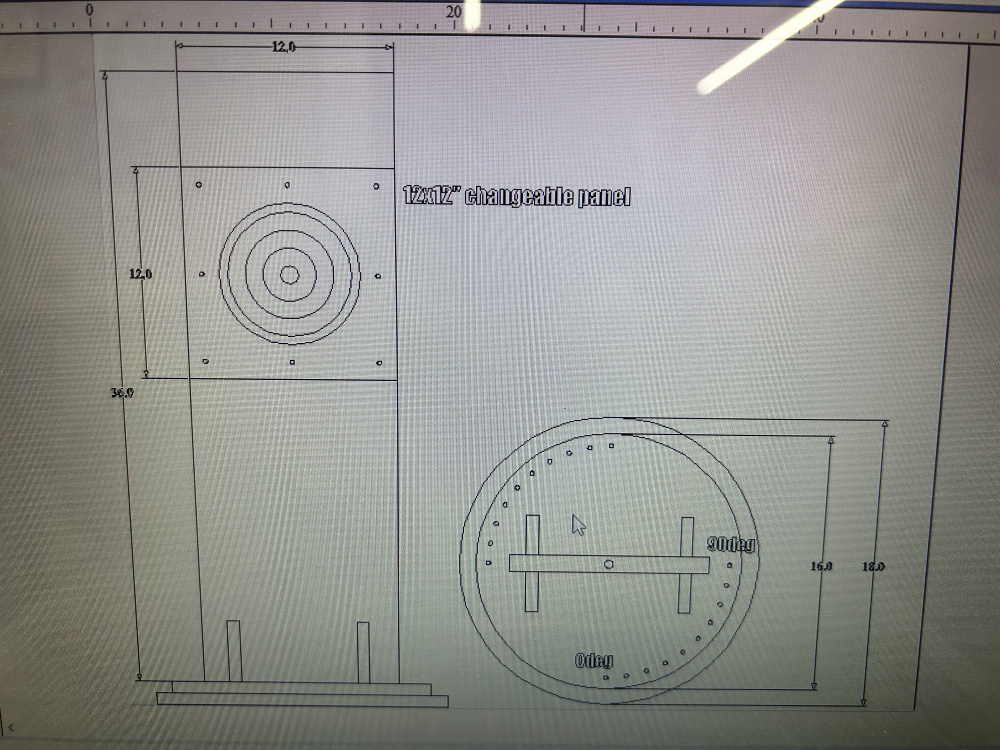

Measurement turn table

I want to build a simple measurement turn table so I can do off axis measurements Easier. What would you say would be a good baffle width. this one is a 12 inch wide.

Comments

Seems OK to me if you want baffle step, but you'll need some sides unless you want the dipole response. If you are measuring drivers for sale I'd read up on the IEC standard for measurement baffles (268-5?). Generally super wide 4 feet iirc.

Thank John. It would be for me mostly. I have a 2x3 ft one now but moving the mic sucks.

https://www.jfcomponents.com/

https://www.jfcomponents.com/

It was a lot of mic movement.

https://www.jfcomponents.com/

I showed my turntable in a thread here. I believe it was 9.5". I need to post the adapter plate that I made.

Thanks Nick

https://www.jfcomponents.com/

I built a large 52.5 x 64" IEC test baffle and mounted it directly to my DIY turntable. I can manually rotate the entire baffle 360 degrees in 7.5 degree increments. It has several 5.25 x 5.25" removable inserts for flush mounting tweeters and several 9.5 x 9" removable inserts for flush mounting mids or woofers up to 8" in diameter. My microphone stays in a fixed position about 60" above the floor and at a distance of about 1 meter or so for all measurements. The reason for going this large was because I wanted to push the diffraction ripple to lower frequencies, so that I could see clearly what the driver itself was doing in 2 Pi space. With smaller baffle dimensions, the ripple will push up into the mid and higher frequencies and mess up your measurements.

I use to have a full size IEC test baffle with removable inserts. It was very helpful when I was first starting out and almost exclusively using PE buyout drivers that had no manufacturer's FR curves available. I would capture my own IB FR curves and simulate on baffle responses with Jeff's spreadsheet before cutting any wood.

Now a days I use higher quality drivers that have published and believable data. My IEC test baffle sat in the corner for years before I finally scrapped it this last Spring.

Guess I should have read the whole thread then I would have seen the need for an IEC test baffle

I built a 4 foot wide test baffle out of cardboard. I never got around to figuring out how to attach it to my turntable. I really liked the cardboard as it was easy to cut out opening for drivers and flush mount them with packing tape. Easy to repair also.