Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Any tips on bending 1/8-inch Masonite/hardboard?

Hi All,

The thread title pretty much states the question. I want to build a curved cabinet, pretty much like the image below which I don't think are particurlarly tight curves (?). I want to use many layers of 1/8-inch Masonite/hardboard. Some hardboard is tempered on only one side and rough on the other, but the stuff I have is tempered (smooth) on both sides.

I'd like to avoid kerfs if possible, but I can cut 1/16" deep kerfs if needed. I think that would make the bending pretty easy (maybe), but then I have to make sure that I use a glue that will fill these voids. I used Gorilla Glue on my only curved speakers to date, which were layers of 1/8-inch Baltic Birch, but they were modest sized bookshelf speakers and the ones I am making now are actually bigger than those in the picture.

I saw some threads where people soaked with Windex or 409 cleaner (supposedly Ammonia is the key). Any thoughts/experience with that??

Edit: I also have a heat gun if that would be useful. (For either bending them or burning them when I get frustrated.)

@ugly_woofer - I wasn't around when you made your Peanuts, but I've seen the pictures and have to think those were some pretty tight curves, so any advice would be great.

Comments

Those ^ actually look like translam construction but I too am interested in bending masonite for this purpose - I know Tom Zarbo has some experience with this type of construction over on PETT - might ask over there too.

Yes, those are translam but mine will be curved Masonite.

I googled "curved Masonite panel speaker cabinet" and found this build.

https://htguide.com/forum/mission-possible-diy/build-stories/37117-curved-dayton-rs-tmww-speaker-build?38007-Curved-Dayton-RS-TMWW-Speaker-Build=&highlight=curved

https://www.finewoodworking.com/2019/10/07/how-to-make-a-two-part-bending-form

If you can find some bending plywood, maybe special order from woodcraft? It is typically 10mm thick. They will ask you, Barrel or post? You are wanting to make something similar to a barrel. I haven't purchased any for quite a few years and my supplier in Louisville has a 1000 dollar min. purchase. Message me if you would like me to put a sheet or two on my next order. I could even precut for you, so it would all fit in a car.

There’s bendable Plywood all over google I got some from amazon a few years ago. 20 some years ago we ordered it from Select Sale out of Florida which I believe is called mobile solutions now. Masonite tho you might need the build a steam box.

https://www.jfcomponents.com/

Thanks guys, I want to use hardboard because several layers becomes VERY stiff and dense (and unfortunately heavy). I will finish the "skeleton" tonight and I have the hardboard all cut and ready to start assembling tomorrow. Just trying to incorporate other's experience to saves myself painful learning and mistakes.

Tom used a form from both sides of the curve, and ratcheted them down into place.

What you have on the Vapor Derecho I would call fairly tight curves. I can say that was my fave of the Vapor builds I got to hear.

InDIYana Event Website

I really hate the Masonite hardboard. The cut ends are always fuzzy and the stuff explodes with screw holes. I'd use Luan underlayment or MDF over the Masonite. The Bendy plywood is is something I'd like to try. Kerfing MDF is easy for me.

I used 1/8" hardboard on my Kowaxial speakers. Bought several 4x8 foot sheets of it at Home Depot when they were selling it for about $5 a sheet. I had the store cut the big sheets into 16" wide strips. I sandwiched six layers to get a total thickness of 3/4. It was super rigid. Used lots of Titebond II and a custom clamping fixture. Be sure to put stop blocks at both ends and along the sides of your clamping fixture. The panels will float on the glue and attempt to "escape" when you apply pressure.

https://projectgallery.parts-express.com/uncategorized/kowaxial/

I tried kerfing for the first time (1/2 in Baltic Birch) for an internal bend on my latest project. Clamped in place, first brushed in a good amount of wood glue, followed by packing (into the cuts) a mixture of wood glue and sawdust, and later sanded. Worked out w/o issues.

Here is the page of the PETT thread that covers the glue up process (pages 6 and 7):

https://techtalk.parts-express.com/forum/tech-talk-forum/1340673-dayton-cx150-8-coaxial-project/page6

For my Peanuts build, I kerfed the 1/8" masonite with a Freud blade that made to vee shaped cuts per pass. I remember specifically looking at the kerf patterns of blades. I think it was a LU88, but I'm not sure. I can look when when I get home, if you're interested. I believe that I only used 3 or 4 layers, because it was so stiff at that thickness.

How deep did you make the cuts and how far apart or was it based on some calualtion for the radius of the bend?

I don't need to know the blade, but to add to Ani's questions... What glue did you use?

I'll do some experimenting tonight, but right now I think with a heat gun and a jig I'll be okay. I ordered a gallon of Titebond II Extend to be delivered tomorrow.

I've done two curve sided enclosures using 1/8" thick Masonite. One was a medium sized bookshelf (my Gormachos project) that was curved from wide at the bottom to narrow at the top. The other was a tall tower speaker (my Agendas project) curved from 10.5" wide at the baffle back to 5" wide at the rear panel. Both projects ended up only needing 4 layers total, so 1/2" thick curved walls. They are extremely stiff (strong) at that seemingly thin thickness. I just used Titebond II glue applied with a smooth foam roller to both surfaces. Spead it on thin because 90% of the glue will get squeezed out (trust me). Just make sure to rough up the smooth as glass surface of the Masonite with some 150 grit sand paper so the glue can soak in and get a bite.

I saw a video that Tom Zorbo made where he demo'd how he built a small pair of curve sided speakers (Overnight Sensations maybe?) In that video he glued up the layers (don't remeber if it was 3 or 4) all at the same time. I didn't do that. I made a clamping jig that matched the curve side profile and only did one layer at a time. The force to bend one 1/8" layer of Masonite isn't really that much. Bending 3 or 4 or maybe more layers at once... forget about it IMHO.

Anyway, I didn't need any Windex or a heat gun to get the Masonite to bend smoothly. Obviously if you do it like I did gluing on only one layer at a time x 2 sides x 2 speakers and letting each glue up dry over night you are looking at 8 days just to do the curved sides. That's my take on it all anyway

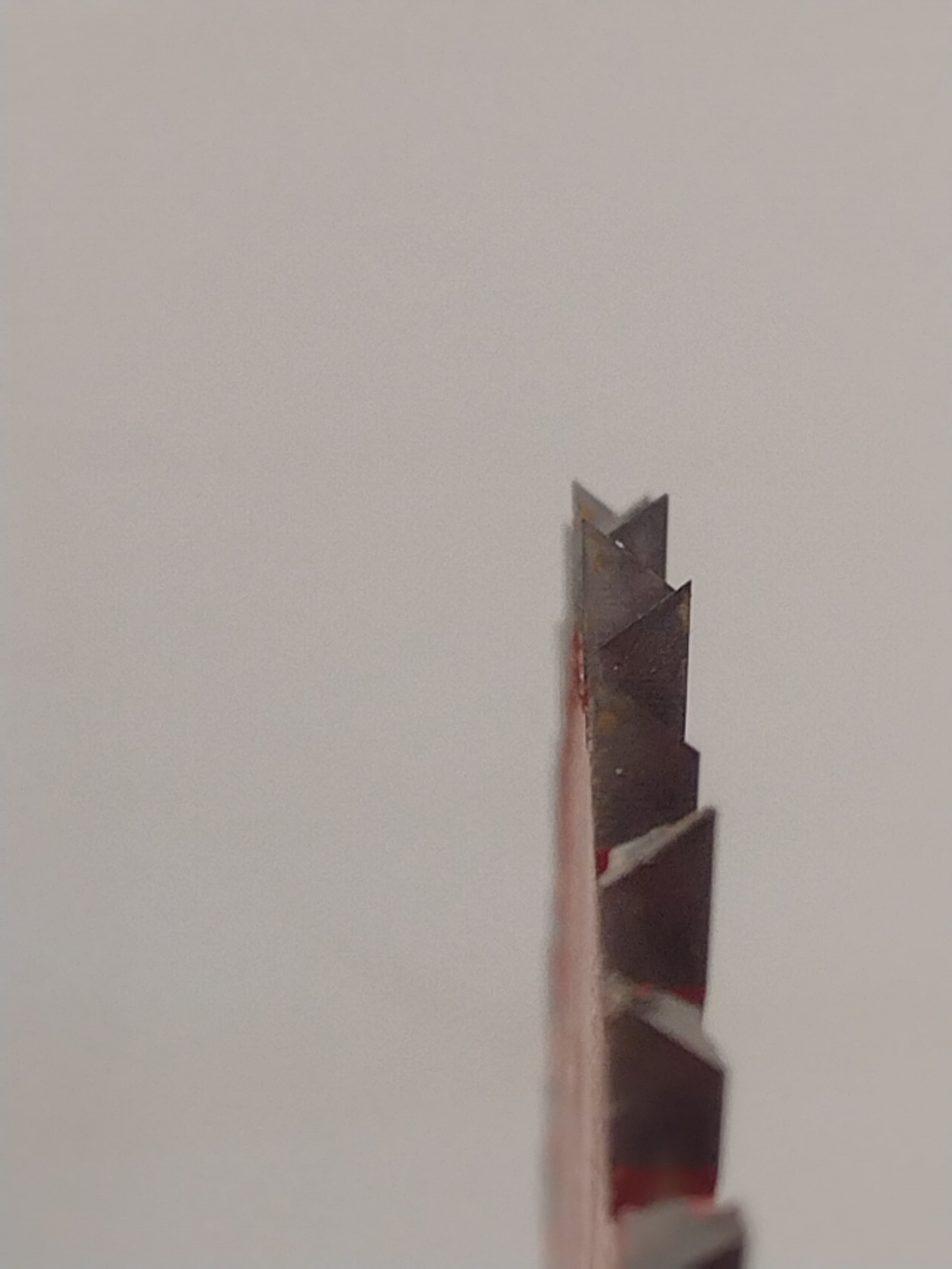

This is the blade profile, so you can see the vee shaped kerfs. I only cut about half way through, so roughly 1/16", and I spaced the cuts about 1/8" apart.

For adhesive I used epoxy and slow setting hardener.

Looks like a 40 degree ATB or High Alternate top bevel.

On a tablesaw I am guessing?

@Eggguy - he mentioned LU88 above, it is the Diablo LU88 thin kerf table saw blade.

Thanks Craig, this is pretty much my current plan. I'll mock up a test piece and see if I need heat gun or kerfs.

Egguy is correct, it's actually a Freud LU80.

I used a radial arm saw to make the cuts.

That would be the easiest way too.

InDIYana Event Website

Mine are a little bigger than the Peanuts at 47-1/2 tall x 18-1/2 deep. I'm optimistic that I can curve without kerfs, hopefully will find out tonight.