Mine were swapped out for dayton pa200s in the original build i tried em in. IMO the Daytons have warmer less dry tone, meatier bottom end, and cleaner fr in crossover zone. Probably 2x the driver but 2x the $ too. So it's a wash for value per dollar I'd say.

Sitting waiting for me to do something with them. Was planning to gut a previous build and reuse the cabinets. I'll probably get to it as the weather kills off other activities.

Out come the SB20FRPC30s and beastmodes. Gonna flip the box upside down and make an extra baffle plate to seal the tweeter hole and cover the woofer gasket. I trimmed down the woofer gasket more flush with the frame so the baffle plate should fit better. The trimming was an experiment of it's own. Which was sort of a success, but isn't pretty. Good thing it'll be covered.

The rear port needs to be half the current length for this woofer. I had originally glued it in with silicone, and it shrugged off my best efforts to remove it without destroying things. I'll just get em with the dremel wheel. All the bracing inside the cabinet would make it a nightmare to get any tool in there enough to make the whole cut.

Chopped up some of the 1/2" thick shelving board for baffle plates and hit it with 3/8" roundover. Might paint it all a charcoal color. With exposed screws holding the baffle plate on I suspect it will take on an early 1900s industrial look... IE: "steampunk" but with less flair.

I was planning on repainting the cabinet charcoal too, but sounds like folks like the blue.. Not a big deal to me. If it stays blue it saves me the trouble. White baffle? hmm. Gives me retro mini fridge vibes.

Drilled screw holes in the baffle board and screwed one of the drivers in. Then a car hit a nearby power pole and probably out of power the rest of the day.

@DrewsBrews said:

... Then a car hit a nearby power pole and probably out of power the rest of the day.

Continued working with battery drill and flashlight on one of the speakers. Predrilled the screw holes and trimmed some thin hobby sheet foam as a giant gasket. Front is now buttoned up enough for testing. Just need power back to run some woops.

Some quick woops for funzies. I didn't get all the measurements I need/want so I'll remeasure later. Interesting to see that 6-7khz trough is gone and instead is a much smaller deep suckout at 6k (pre smoothing).

Probably need some off axis to see what is realing going on with the tweeter. Complete guess, but on axis looks like a ~2-2.5khz -6db point might be doable with a 2nd order electrical. Would have a big impedance peak at xo like most horn loaded passive designs end up with. That sub1k woofer hump doesn't look fun to deal with though.

Got some measurements I can start working with. Ignore below 500hz because I'm a weirdo.

Sofar just 3rd order electrical on both with some tweeter padding. But this causes impedance to go for the moon due the influence of all that horn loading from the woofer cone.. so probably not the best way to go about it. Guess I need to cross higher.

@Billet said:

I'd cross over at 7.5k, low freq driver running full range, and give it a good listen... Based on your raw data from November, that looks very doable.

My 2 cents…could bring in a 1st order LP ~8500 (maybe lower) to attenuate the 4700-7200 ish rise just a tad (almost letting it run full kilt) and then play with tw HP (trying 2nd or 3rd order) to fit. My last Celestion coax I did as per Billet suggested (with a 3rd order HP passive in tw and let the mid run full)- worked great - but then again I use an active eq over-top passive for the coax. My next build - pulling these Celestions and HP filter thinking adding LP to the mid (of the coax).

Finally got around to getting the second driver and baffle plate mounted up.. Only to find there is an obvious VC/former rub once mounted. This project might be cooked unless I can get some sand paper down to the glue in the gap as a last ditch attempt to save it. That's why I play with cheap stuff.

I found some 320 grit and cut a sliver to slide in the gap. Moved it around to where things got tight and focused on that area. Took a few rounds but I think it is OK for now, at least until the driver gets removed and re-mounted.

I tried the 2nd crossover attempt. I had all the parts on hand in spares or scrounged from old crossovers except the 5.1uf. $7 and a trip to PE I had some cheap Daytons. For once I was able to mock up both speakers at once to listen.

There was barely any acoustic offset, almost off the bottom of what WinPCD will accept (only so many decimal places). I can tell since I can move my head around and stand up without the "warble" effect. Only the HF fades. That will take some getting used to.

Sounds stage is nice, instrument locations seem more defined than I'm used to hearing.

I plopped the mic down with the speaker still in position next to the tv. Cranked it to get enough above noise floor for some distortion measurements. On FR, orange is on axis, green is off axis as if there was no toe-in.

The 800hz region is still a problem. I was ignoring the shout durring the listening sessions. Since so many 8" have that I imagine it is the gasket dimension issue (and baffle plate opening in my case). On top of that I need to figure out a crossover that has minimal resistance on the tweeter.

This might go on hold again until I decide if it is worth trying a different enclosure and baffle setup.

Anyone had experience removing these kind of gaskets entirely?

Comments

Super Glue isn't that great when it comes to bonding plastic. They are much better glues made for that application.

.

I love them GRS 8’s for the money. I built these for a local guy in a 3200 sq.ft build and they are impressive!!!!

https://www.jfcomponents.com/

I bet all of those together really get it done!

Mine were swapped out for dayton pa200s in the original build i tried em in. IMO the Daytons have warmer less dry tone, meatier bottom end, and cleaner fr in crossover zone. Probably 2x the driver but 2x the $ too. So it's a wash for value per dollar I'd say.

Curious what ever came of these?

Sitting waiting for me to do something with them. Was planning to gut a previous build and reuse the cabinets. I'll probably get to it as the weather kills off other activities.

Gosh 8pt-8 is on sale for ~$20ea right now. Trying hard to not think of goin balls out and doing a tower 888 style.

They wouldn't be the biggest speaker you've built. I say go for it.

Out come the SB20FRPC30s and beastmodes. Gonna flip the box upside down and make an extra baffle plate to seal the tweeter hole and cover the woofer gasket. I trimmed down the woofer gasket more flush with the frame so the baffle plate should fit better. The trimming was an experiment of it's own. Which was sort of a success, but isn't pretty. Good thing it'll be covered.

The rear port needs to be half the current length for this woofer. I had originally glued it in with silicone, and it shrugged off my best efforts to remove it without destroying things. I'll just get em with the dremel wheel. All the bracing inside the cabinet would make it a nightmare to get any tool in there enough to make the whole cut.

Chopped up some of the 1/2" thick shelving board for baffle plates and hit it with 3/8" roundover. Might paint it all a charcoal color. With exposed screws holding the baffle plate on I suspect it will take on an early 1900s industrial look... IE: "steampunk" but with less flair.

I DIG IT!

Looks like old Altec.

That baffle would look great in charcoal, or possibly gloss white...

I was planning on repainting the cabinet charcoal too, but sounds like folks like the blue.. Not a big deal to me. If it stays blue it saves me the trouble. White baffle? hmm. Gives me retro mini fridge vibes.

@kenrhodes what the heck are those??

I think those are altec 605. They had a lot of monitors like that in the late 50's and 60s.

Piqued my interest so I went searching. I think the drivers are 615B. Those are pretty wild looking!

https://usaudiomart.com/details/649349352-altec-615b-duplex-coaxial-pair-mint-condition/images/1519380/

Like Ken said.. In their studio monitor cabinets. Which, as far as I can tell, were commonly found with silver hammertone type paint.

Drilled screw holes in the baffle board and screwed one of the drivers in. Then a car hit a nearby power pole and probably out of power the rest of the day.

That sucks! Hope you get powered back up soon!

What?

Continued working with battery drill and flashlight on one of the speakers. Predrilled the screw holes and trimmed some thin hobby sheet foam as a giant gasket. Front is now buttoned up enough for testing. Just need power back to run some woops.

Some quick woops for funzies. I didn't get all the measurements I need/want so I'll remeasure later. Interesting to see that 6-7khz trough is gone and instead is a much smaller deep suckout at 6k (pre smoothing).

Probably need some off axis to see what is realing going on with the tweeter. Complete guess, but on axis looks like a ~2-2.5khz -6db point might be doable with a 2nd order electrical. Would have a big impedance peak at xo like most horn loaded passive designs end up with. That sub1k woofer hump doesn't look fun to deal with though.

Got some measurements I can start working with. Ignore below 500hz because I'm a weirdo.

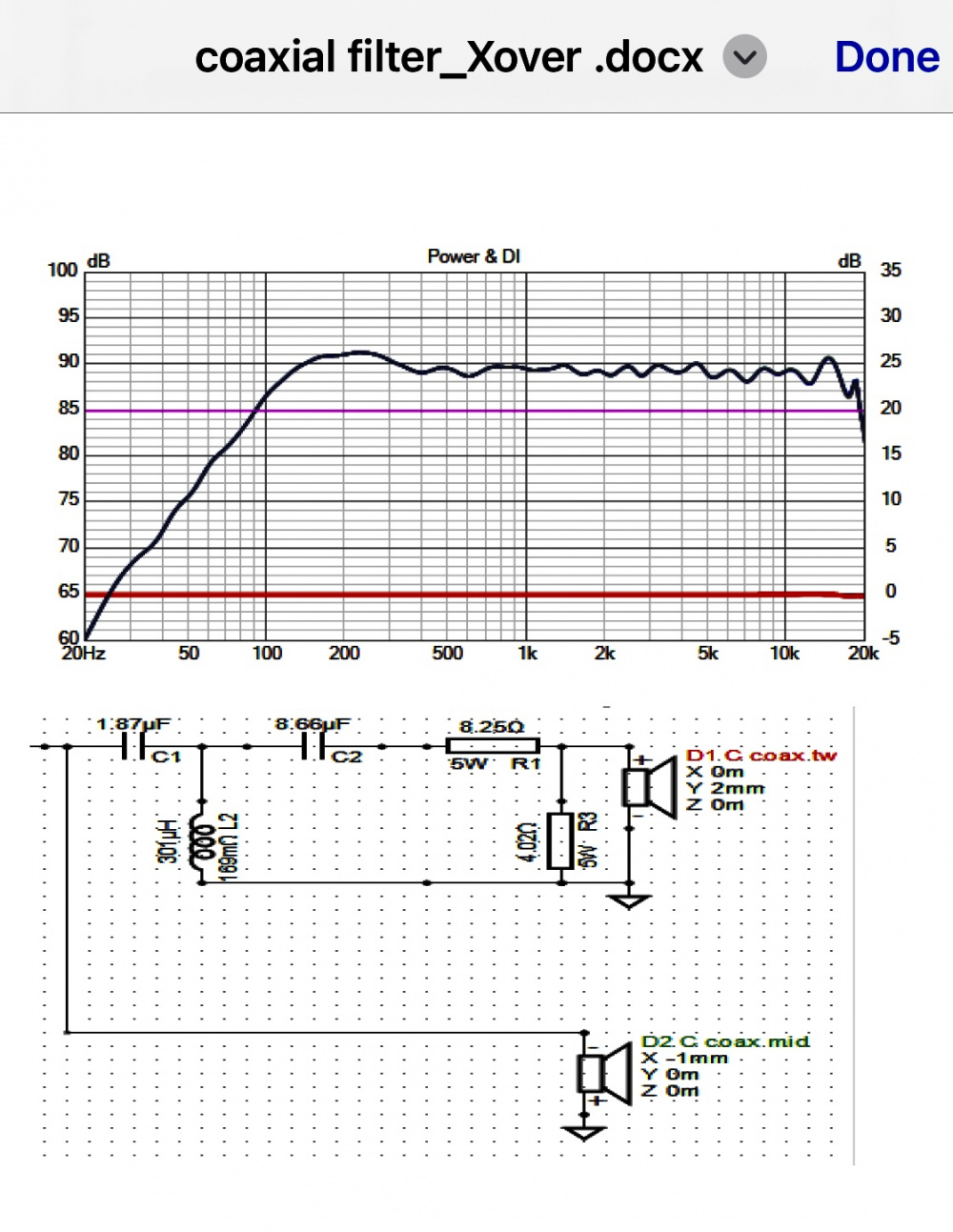

Sofar just 3rd order electrical on both with some tweeter padding. But this causes impedance to go for the moon due the influence of all that horn loading from the woofer cone.. so probably not the best way to go about it. Guess I need to cross higher.

`Lil better. Impedance only shoots up to under 45ohm this time, instead of over 60. Looking a bit less.. congested I guess.

3.5K might be the sweet spot.

All the coaxes I've messed-with over the years XO'd between 3K and 5K . . .

I'd cross over at 7.5k, low freq driver running full range, and give it a good listen... Based on your raw data from November, that looks very doable.

Sofar seems like that is about as good as it's gonna get.

My 2 cents…could bring in a 1st order LP ~8500 (maybe lower) to attenuate the 4700-7200 ish rise just a tad (almost letting it run full kilt) and then play with tw HP (trying 2nd or 3rd order) to fit. My last Celestion coax I did as per Billet suggested (with a 3rd order HP passive in tw and let the mid run full)- worked great - but then again I use an active eq over-top passive for the coax. My next build - pulling these Celestions and HP filter thinking adding LP to the mid (of the coax).

Finally got around to getting the second driver and baffle plate mounted up.. Only to find there is an obvious VC/former rub once mounted. This project might be cooked unless I can get some sand paper down to the glue in the gap as a last ditch attempt to save it. That's why I play with cheap stuff.

I found some 320 grit and cut a sliver to slide in the gap. Moved it around to where things got tight and focused on that area. Took a few rounds but I think it is OK for now, at least until the driver gets removed and re-mounted.

I tried the 2nd crossover attempt. I had all the parts on hand in spares or scrounged from old crossovers except the 5.1uf. $7 and a trip to PE I had some cheap Daytons. For once I was able to mock up both speakers at once to listen.

There was barely any acoustic offset, almost off the bottom of what WinPCD will accept (only so many decimal places). I can tell since I can move my head around and stand up without the "warble" effect. Only the HF fades. That will take some getting used to.

Sounds stage is nice, instrument locations seem more defined than I'm used to hearing.

I plopped the mic down with the speaker still in position next to the tv. Cranked it to get enough above noise floor for some distortion measurements. On FR, orange is on axis, green is off axis as if there was no toe-in.

The 800hz region is still a problem. I was ignoring the shout durring the listening sessions. Since so many 8" have that I imagine it is the gasket dimension issue (and baffle plate opening in my case). On top of that I need to figure out a crossover that has minimal resistance on the tweeter.

This might go on hold again until I decide if it is worth trying a different enclosure and baffle setup.

Anyone had experience removing these kind of gaskets entirely?