A little more information. This is a project that I've wanted to build for years now. It is a mini line array using the very efficient buyout Peerless 835004 woofers. I bought 4 before they went NLA. Years later Tom S. gave me 4 more he said were just sitting around and he would never use. Thanks Tom! So there will be four 6.5" woofers on a 32" tall baffle. What has stopped me from building these for so long is finding the right tweeter. Not wanting to use cheap sounding mylar domes or piezos, but also not wanting to spend a ton of money for 2 rows of small format tweeters , like the ND16FA. A week ago I was looking at stuff on Brad's website and noticed the small format tweeters he has for sale with 2" round faceplates. I PM'd him about the possibility of a discount for a large quantity order. Brad hooked me up. Thanks Brad! Here are the 25 little buggers:

I measured all 25 of them with DATS last night and their impedance curves are all exactly the same. So there will be a row of 12 on each speaker. Not much more to say at this point other than these will be super sensitive, and easily get stupid loud, but definitely need subs because their F3 is only 58 Hz. Time to start making some holes, lot's of holes LOL!

Since they are Daleks, do you have plungers picked out for each channel? Exterminate! :^)

Jokes aside, line Arrays are interesting and take some time to build. Holey moley...

Literally - need to invest in some hole saws and rabbiting router bits . . . I'm interested in what you think of those tweeters as I have a pair looking for a project, sir.

Going "full lazy" on this one. 1-3/8" spade bit in the drill press for the tweeter through hole. Surface mounted tweeters and woofers. Diffraction can kiss my grits!

Took me almost 2 hours to precisely lay out the driver locations, all 32 of them! Time to start making some particle board dust. Need to employ my Son to do the ShopVac thing while I bore 24 tweeter through holes.

That went way better and quicker than I expected. The 24 tweeter holes are done! My Son helped by doing the ShopVac thing and it really made a big difference. It's cold outside here today, 32°F, but I want to move forward with this project so stocking cap and gloves on... router dust will be flying!

@PWRRYD said:

That went way better and quicker than I expected. The 24 tweeter holes are done! My Son helped by doing the ShopVac thing and it really made a big difference. It's cold outside here today, 32°F, but I want to move forward with this project so stocking cap and gloves on... router dust will be flying!

So, ? Sounds like you should have had you son lay out the driver locations as well... jk

@PWRRYD said:

That went way better and quicker than I expected. The 24 tweeter holes are done! My Son helped by doing the ShopVac thing and it really made

So, ? Sounds like you should have had you son lay out the driver locations as well... jk

I bet he could. He's way smarter than I am. He got his brains from my Dad! Dad could do or figure out ANYTHING! Wish he was still around to see my Son and Daughter do so well.

For a moment I thought you might be making a cabinet like this:

Maybe with a tweeter at the end of the Dalek's gun?!

Seriously, there was a Bang and Olufsen speaker which looked rather like a Dalek, at least in outline. It was a three way with the usual high price tag.

Started gluing up the first couple of panels. As much as I hate routering driver rebates I still enjoy cutting panels and gluing them up. Reminds me of working on projects with my Dad. He was always building something and I was always his helper. He taught me so much.... wish he was still here to see my kids grow up and go to college.

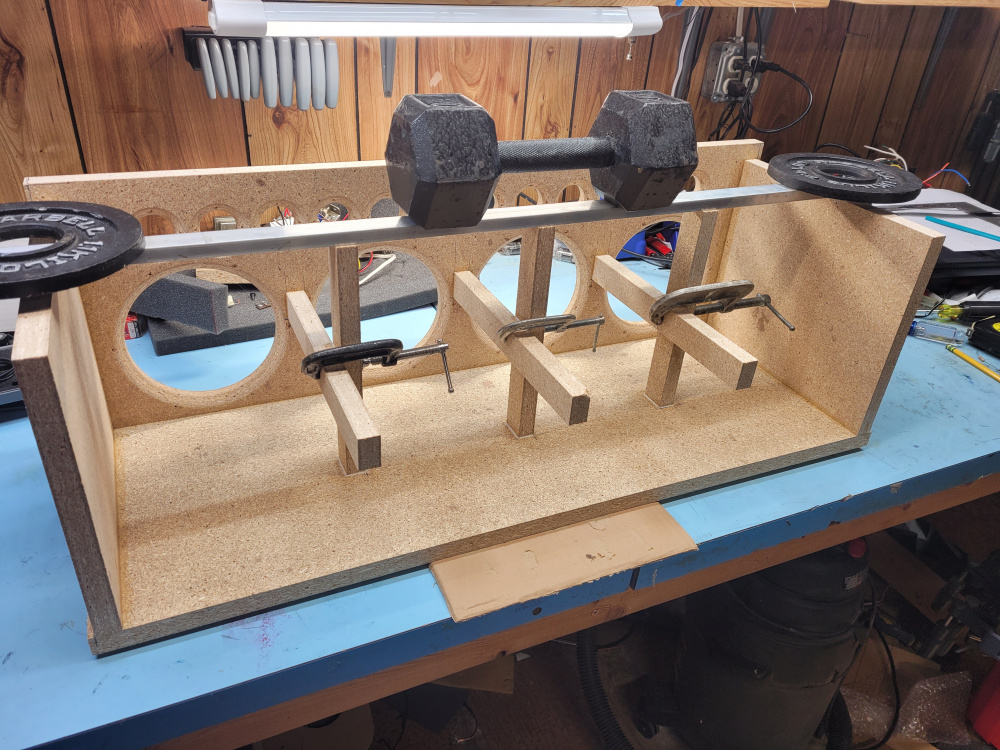

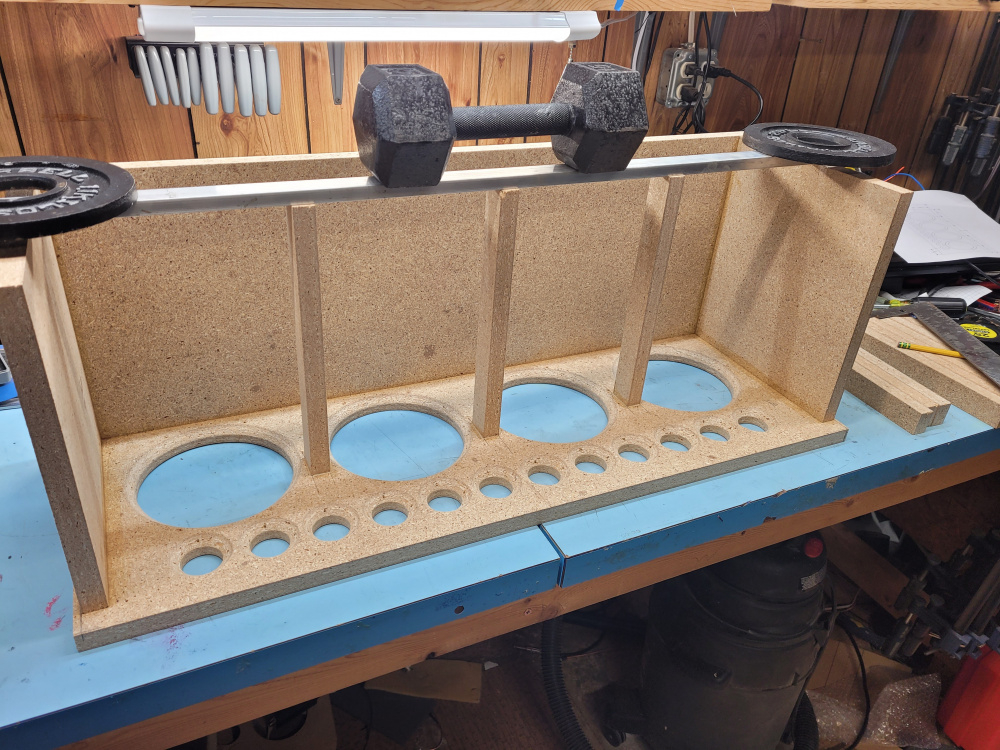

Got the front to back braces glued in after work tonight. They are really needed because these baffles are like Swiss cheese LOL. Next up are the side to side braces. Then I can glue on the last sides. A couple more braces to tie in the top and bottom panels then I can finish up by gluing on the back panels:

So sort of a side note: I need 96 screws to mount all these 24 tweeters. They are small so they need #4 screws. I only had 100 zinc plated #4 screws. Luckily I work at an aerospace plating/metal finishing company.

For several of my projects, I used the Peerless BC25SC06-04 tweeter. I cut all of holes and recesses for that tweeter using a forstner bit and rabbeting bit. The fit was good enough that the tweeters snapped into the recess with a little force by hand. I know I brought some of those designs (Lithium for example) to events without any screws or glue.

Keep an open mind, but don't let your brain fall out.

Almost ready to glue up the last two side panels. This is how I do my bracing. I like to just use the leftover, already cut to perfect width pieces instead of making window braces. Are the window braces better? For sure they are. But I'm lazy and like to use cutoff scraps and a few dabs of wood glue instead. Maybe if these were Purify woofers and RAAAAAL tweeters, then I would make window braces. But they're $10 buyout woofers and <$5 tweeters. That's how I'm rollin on this project.

Comments

won’t have to sweep off the driveway 😁

Anyone notice the missing silver maple tree? That was only a couple thou

federal tax deductions for forest management…

OMG you turned your trees into speakers?

Windy here too. I'm surprised your smaller pieces didn't end up across the street.

Sorry about your tree. It sure isn't something you usually expect and can make big dent in the bank account.

A little more information. This is a project that I've wanted to build for years now. It is a mini line array using the very efficient buyout Peerless 835004 woofers. I bought 4 before they went NLA. Years later Tom S. gave me 4 more he said were just sitting around and he would never use. Thanks Tom! So there will be four 6.5" woofers on a 32" tall baffle. What has stopped me from building these for so long is finding the right tweeter. Not wanting to use cheap sounding mylar domes or piezos, but also not wanting to spend a ton of money for 2 rows of small format tweeters , like the ND16FA. A week ago I was looking at stuff on Brad's website and noticed the small format tweeters he has for sale with 2" round faceplates. I PM'd him about the possibility of a discount for a large quantity order. Brad hooked me up. Thanks Brad! Here are the 25 little buggers:

I measured all 25 of them with DATS last night and their impedance curves are all exactly the same. So there will be a row of 12 on each speaker. Not much more to say at this point other than these will be super sensitive, and easily get stupid loud, but definitely need subs because their F3 is only 58 Hz. Time to start making some holes, lot's of holes LOL!

Since they are Daleks, do you have plungers picked out for each channel? Exterminate! :^)

Jokes aside, line Arrays are interesting and take some time to build. Holey moley...

InDIYana Event Website

Literally - need to invest in some hole saws and rabbiting router bits . . . I'm interested in what you think of those tweeters as I have a pair looking for a project, sir.

Going "full lazy" on this one. 1-3/8" spade bit in the drill press for the tweeter through hole. Surface mounted tweeters and woofers. Diffraction can kiss my grits!

Took me almost 2 hours to precisely lay out the driver locations, all 32 of them! Time to start making some particle board dust. Need to employ my Son to do the ShopVac thing while I bore 24 tweeter through holes.

That went way better and quicker than I expected. The 24 tweeter holes are done! My Son helped by doing the ShopVac thing and it really made a big difference. It's cold outside here today, 32°F, but I want to move forward with this project so stocking cap and gloves on... router dust will be flying!

The late Lou C used those woofers in his "Lecbos" MTMs and noted that they sounded pretty nice!

Geoff

So, ? Sounds like you should have had you son lay out the driver locations as well... jk

I bet he could. He's way smarter than I am. He got his brains from my Dad! Dad could do or figure out ANYTHING! Wish he was still around to see my Son and Daughter do so well.

Ok back to this project. I had a super productive day despite the cold weather:

That really looks cool.

For a moment I thought you might be making a cabinet like this:

Maybe with a tweeter at the end of the Dalek's gun?!

Seriously, there was a Bang and Olufsen speaker which looked rather like a Dalek, at least in outline. It was a three way with the usual high price tag.

Looks an awesome project!

Geoff

Wow, just got started but precisely marking and drilling 144 driver mounting holes is time consuming!

Whew! Glad that's done. Now I can start gluing up the enclosures.

Started gluing up the first couple of panels. As much as I hate routering driver rebates I still enjoy cutting panels and gluing them up. Reminds me of working on projects with my Dad. He was always building something and I was always his helper. He taught me so much.... wish he was still here to see my kids grow up and go to college.

Clamps off.... no more talk of Dad.

Got the front to back braces glued in after work tonight. They are really needed because these baffles are like Swiss cheese LOL. Next up are the side to side braces. Then I can glue on the last sides. A couple more braces to tie in the top and bottom panels then I can finish up by gluing on the back panels:

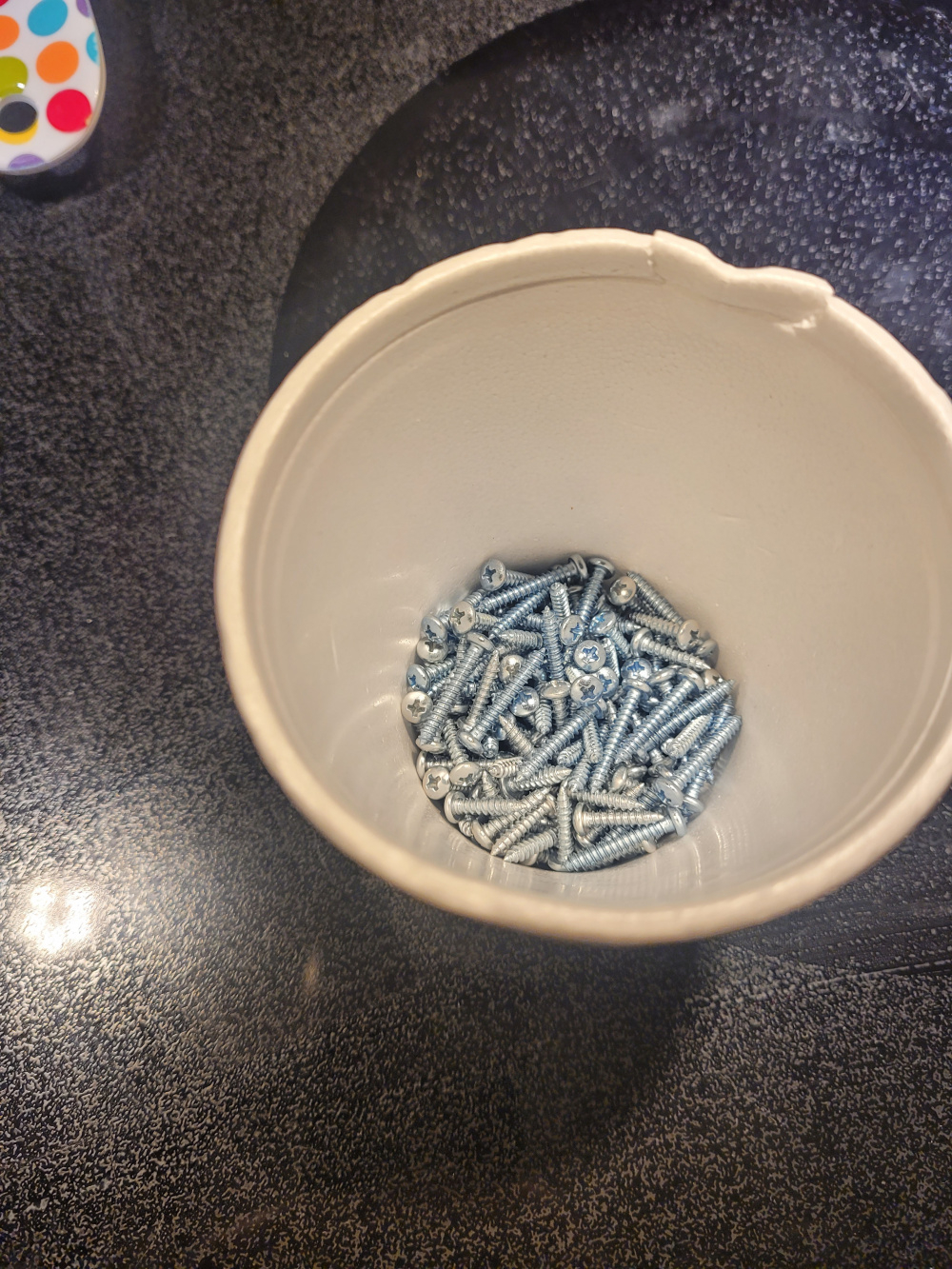

So sort of a side note: I need 96 screws to mount all these 24 tweeters. They are small so they need #4 screws. I only had 100 zinc plated #4 screws. Luckily I work at an aerospace plating/metal finishing company.

Shiny zinc plated screws from Menards (cheap):

Black zinc dichomated screws:

I'd be tempted to glue them because I'm lazy.

Glue the tweeters?

yup a dab on two spots. Maybe a combo of yellow and CA. Should be easy enough to pop off. Plus easy to align or match the openning

Your stock is dropping Number 2.

You should sell some screws on the side.

For several of my projects, I used the Peerless BC25SC06-04 tweeter. I cut all of holes and recesses for that tweeter using a forstner bit and rabbeting bit. The fit was good enough that the tweeters snapped into the recess with a little force by hand. I know I brought some of those designs (Lithium for example) to events without any screws or glue.

Sehlin Sound Solutions

Almost ready to glue up the last two side panels. This is how I do my bracing. I like to just use the leftover, already cut to perfect width pieces instead of making window braces. Are the window braces better? For sure they are. But I'm lazy and like to use cutoff scraps and a few dabs of wood glue instead. Maybe if these were Purify woofers and RAAAAAL tweeters, then I would make window braces. But they're $10 buyout woofers and <$5 tweeters. That's how I'm rollin on this project.