Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Who's Online (0)

Kozo: A Compact High Performance Three Way

The final speaker:

A half cubic foot, F3 of 42 hz, and capable of just under 104db down to 35 hz with 60 watts of power. Boom. Headshot.

Build progress:

Clamp

Clamp Again

Box Ready to Test

Copper is ready! Are you?

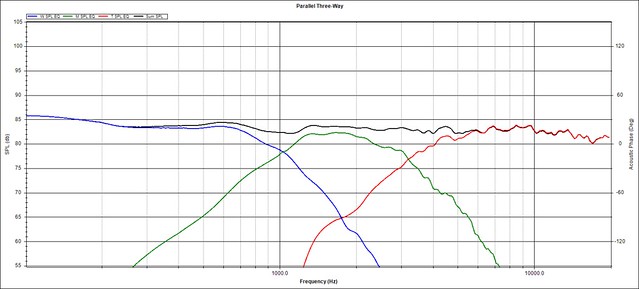

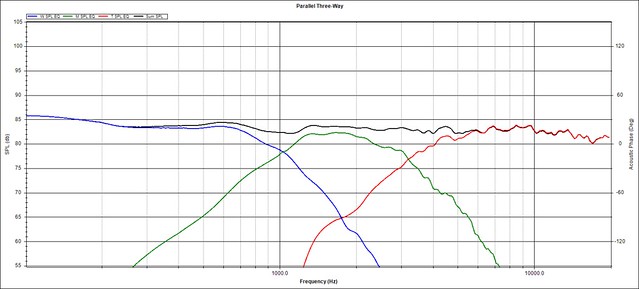

Ok, enough of that. I am going to cut and paste a bit about my design choices here from the PDF with all the build details you can nab below. First the response, the proof is in the pudding or so they say:

Let me see if I can shed light on why each driver was chosen and how it was applied. Ill start from the woofer and work up the response spectrum.

The RS180P-4 is the initial design choice. I had wanted to use this driver for a while. My first RS driver success was using the RS100P, a very nice small midrange and I wanted to explore a larger driver with more bass output. The name of the speaker takes from the paper cone of this newer woofer. Kozo is the Japanese name for the Paper Mulberry Plant, considered by most historians to be the original form of paper as used by the Chinese people long ago. The name Kozo is an homage to paper itself. I chose the 180P-4 specifically because the specs looked good for some nice bass. A lot of the new P line are very nice, but they dont model well for bass extension as compared to their aluminum cone older sisters.

The W3-315E was on sale, and at the price looked to be a knock-out midrange. I had just heard another Tang Band mid in a design by CJD that sounded amazing and wanted to try one in a design. It fit the budget of the context, and responses looked good on paper. When I tested it though, it has highish distortion below 600 hz and above 4000 hz which really limited is usefulness in all but a narrow midrange scenario. In the range I use it though, 900 hz to 3.5 khz, it is a world class performer. I really like the sound of it, and think it remains very neutral, never drawing attention to itself.

The OX20 Ive used more than once. Simply put, it doesnt do anything wrong. It has a modern neo slug motor, optimized chamber, and an amazing product consistency (every one of the eight I have used have measured spot on). I had designed the shallow curved waveguide faceplate after the CSS LD22C, and wanted to use it for a while. I jumped at the chance here to use it in this design. The guide gives the tweeter a boost from 5khz and up of about 3db, which makes the crossover harder. On the other hand, the measurements on it are the smoothest Ive ever seen for the OX20. It really minimizes the interactions of the baffle on the tweeter and removes a lot of the jaggedness youd see normally.

The finish for my pair is a reflection of my love of metal. I am working over the years on refining the perfect distressed or hammered metal look. Lucky for me very convincing Modern Masters Metallic paints exist, and I used these in this build. The process for the finish is as follows:

1) Create and apply the texturing material to the sanded box with a scraper, leaving it rough. Sand down that material when dry (wait a day).

2) Seal the texturing material with a nice oil based primer. I used Kilz Original. Sand that down with 400 grit gently when dry, clean dust off.

3) Spray a base coat of shiny black metal with Rustoleum Hammered Black spray and let that dry.

4) Use two tones (dark and light) of a Modern Masters Metallic paint (I used Antique Copper and Copper). Brush it onto a palette thinly, apply with a sponge gently to get a dry brush effect without brush marks.

The texturing material I used was a mix of Durhams Water Putty, Titebond III glue, and water in a 10:4:3 ratio by volume respectively. This creates a tough, adhesive putty to apply to the box. It begins to dry in minutes though, so you have to work with some speed.

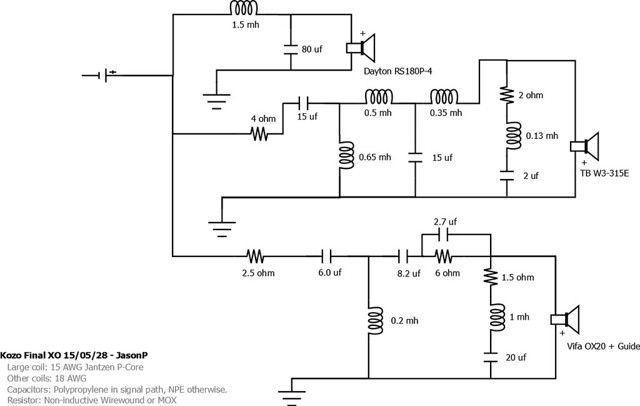

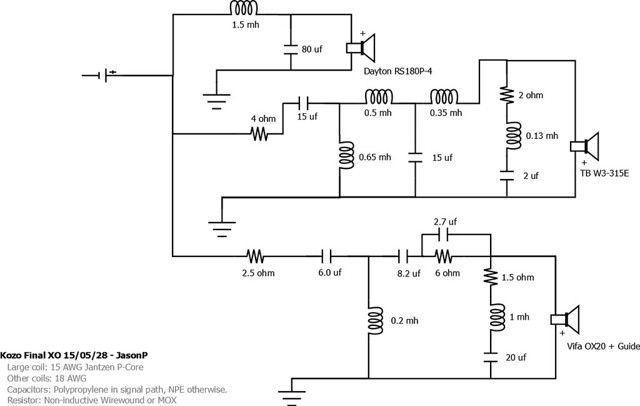

Crossover schematic:

You can get the faceplate from shapeways here: http://www.shapeways.com/product/5FQ...ceplate-3-inch

The PDF with all design details attached: KOZO, A High Performance Compact Three Way.pdf

A half cubic foot, F3 of 42 hz, and capable of just under 104db down to 35 hz with 60 watts of power. Boom. Headshot.

Build progress:

Clamp

Clamp Again

Box Ready to Test

Copper is ready! Are you?

Ok, enough of that. I am going to cut and paste a bit about my design choices here from the PDF with all the build details you can nab below. First the response, the proof is in the pudding or so they say:

Let me see if I can shed light on why each driver was chosen and how it was applied. Ill start from the woofer and work up the response spectrum.

The RS180P-4 is the initial design choice. I had wanted to use this driver for a while. My first RS driver success was using the RS100P, a very nice small midrange and I wanted to explore a larger driver with more bass output. The name of the speaker takes from the paper cone of this newer woofer. Kozo is the Japanese name for the Paper Mulberry Plant, considered by most historians to be the original form of paper as used by the Chinese people long ago. The name Kozo is an homage to paper itself. I chose the 180P-4 specifically because the specs looked good for some nice bass. A lot of the new P line are very nice, but they dont model well for bass extension as compared to their aluminum cone older sisters.

The W3-315E was on sale, and at the price looked to be a knock-out midrange. I had just heard another Tang Band mid in a design by CJD that sounded amazing and wanted to try one in a design. It fit the budget of the context, and responses looked good on paper. When I tested it though, it has highish distortion below 600 hz and above 4000 hz which really limited is usefulness in all but a narrow midrange scenario. In the range I use it though, 900 hz to 3.5 khz, it is a world class performer. I really like the sound of it, and think it remains very neutral, never drawing attention to itself.

The OX20 Ive used more than once. Simply put, it doesnt do anything wrong. It has a modern neo slug motor, optimized chamber, and an amazing product consistency (every one of the eight I have used have measured spot on). I had designed the shallow curved waveguide faceplate after the CSS LD22C, and wanted to use it for a while. I jumped at the chance here to use it in this design. The guide gives the tweeter a boost from 5khz and up of about 3db, which makes the crossover harder. On the other hand, the measurements on it are the smoothest Ive ever seen for the OX20. It really minimizes the interactions of the baffle on the tweeter and removes a lot of the jaggedness youd see normally.

The finish for my pair is a reflection of my love of metal. I am working over the years on refining the perfect distressed or hammered metal look. Lucky for me very convincing Modern Masters Metallic paints exist, and I used these in this build. The process for the finish is as follows:

1) Create and apply the texturing material to the sanded box with a scraper, leaving it rough. Sand down that material when dry (wait a day).

2) Seal the texturing material with a nice oil based primer. I used Kilz Original. Sand that down with 400 grit gently when dry, clean dust off.

3) Spray a base coat of shiny black metal with Rustoleum Hammered Black spray and let that dry.

4) Use two tones (dark and light) of a Modern Masters Metallic paint (I used Antique Copper and Copper). Brush it onto a palette thinly, apply with a sponge gently to get a dry brush effect without brush marks.

The texturing material I used was a mix of Durhams Water Putty, Titebond III glue, and water in a 10:4:3 ratio by volume respectively. This creates a tough, adhesive putty to apply to the box. It begins to dry in minutes though, so you have to work with some speed.

Crossover schematic:

You can get the faceplate from shapeways here: http://www.shapeways.com/product/5FQ...ceplate-3-inch

The PDF with all design details attached: KOZO, A High Performance Compact Three Way.pdf

= Howard Stark: "This is the key to the future. I'm limited by the technology of my time, but one day you'll figure this out."

Comments

Here they are in my home office:

I love these babies!! Thanks JP!!