Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Who's Online (0)

on the reduction of Harmonic Distortion of AMT drivers in lower frequencies

Testing out a modification to an AMT diaphragm to reduce harmonic distortion

The problem:

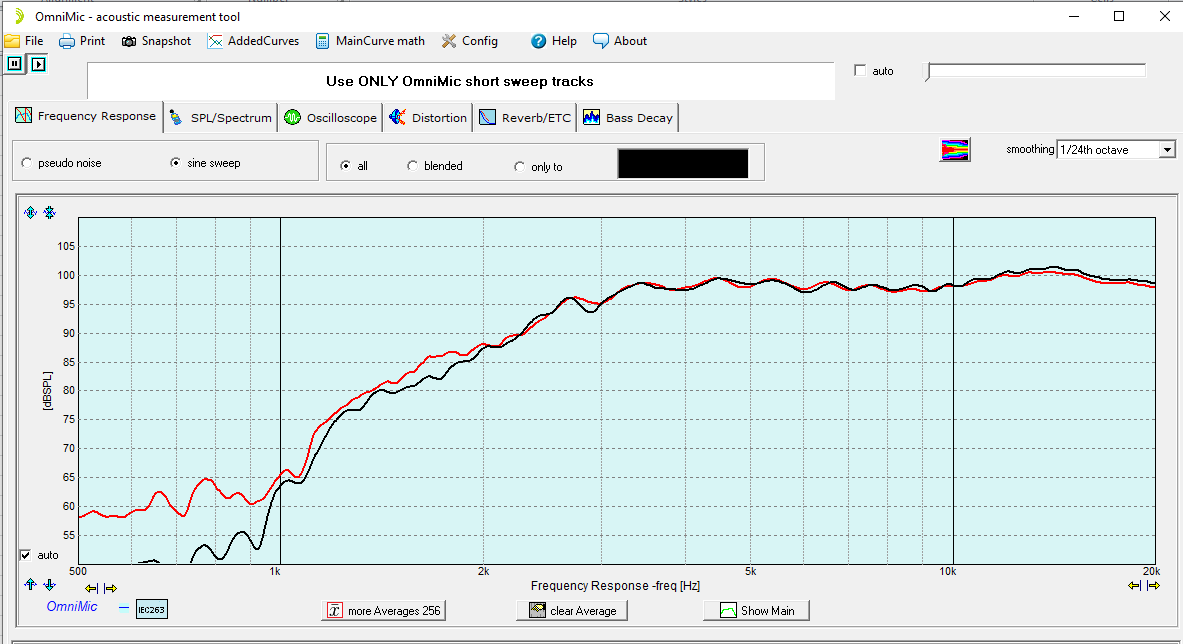

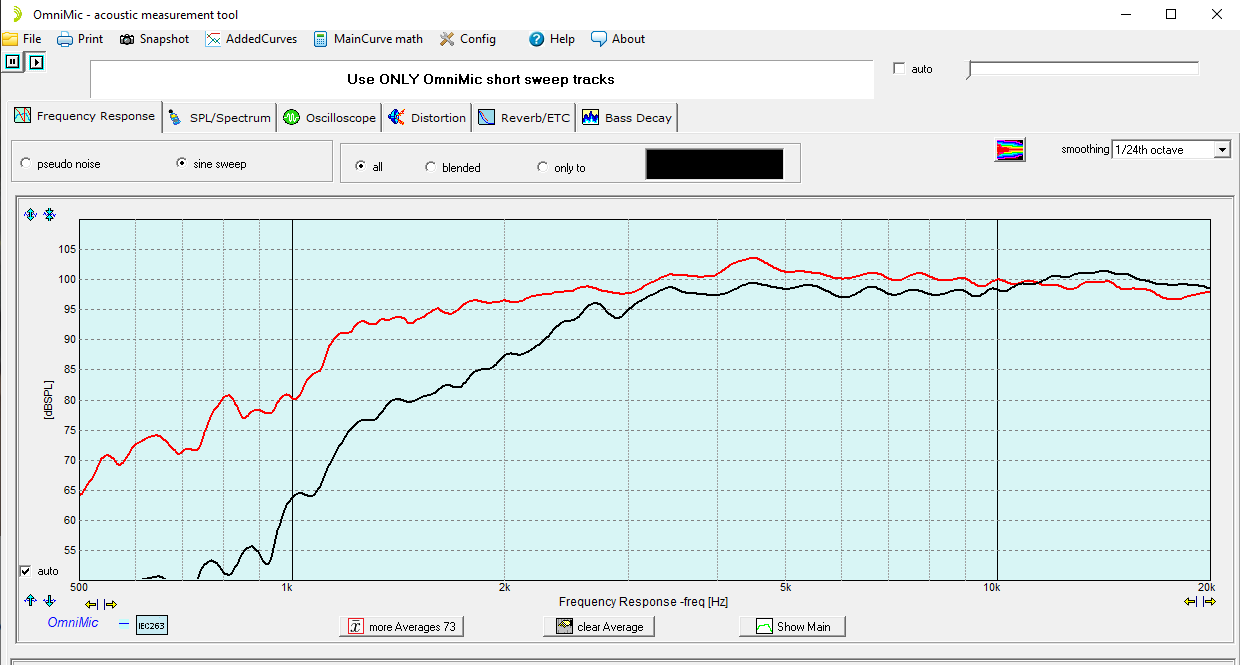

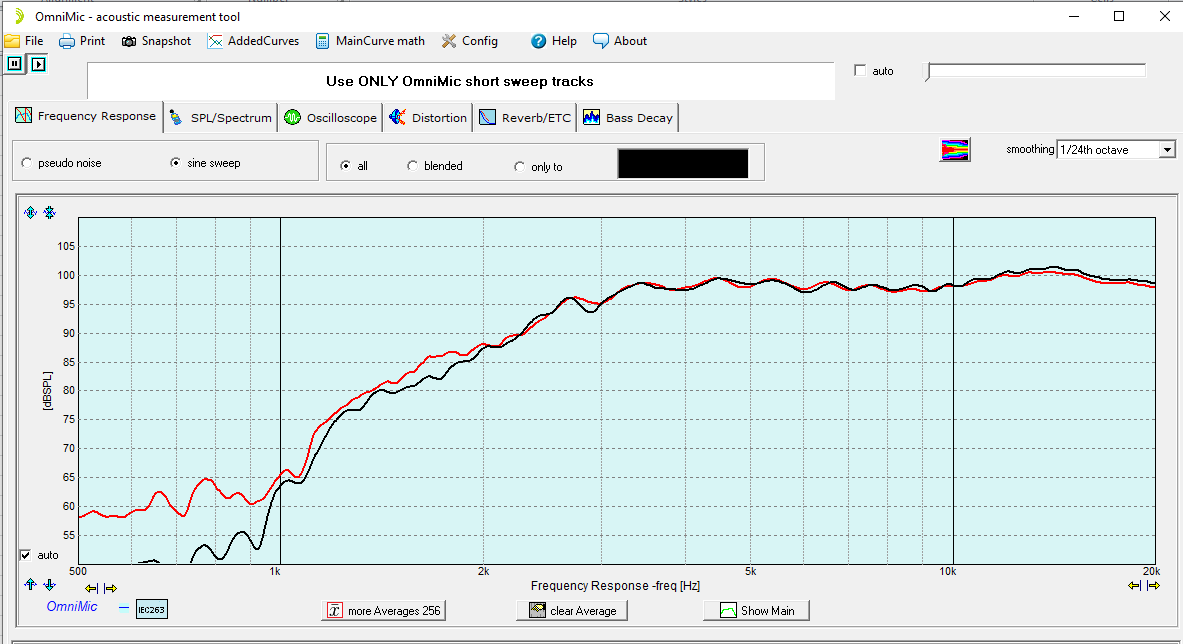

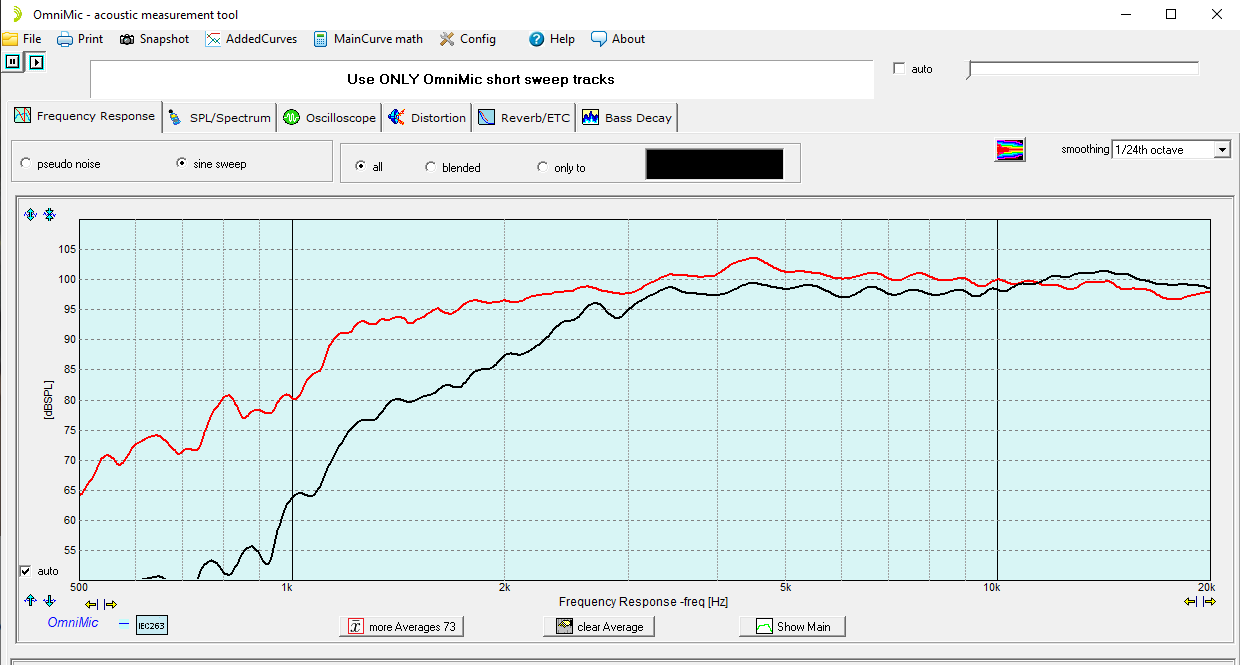

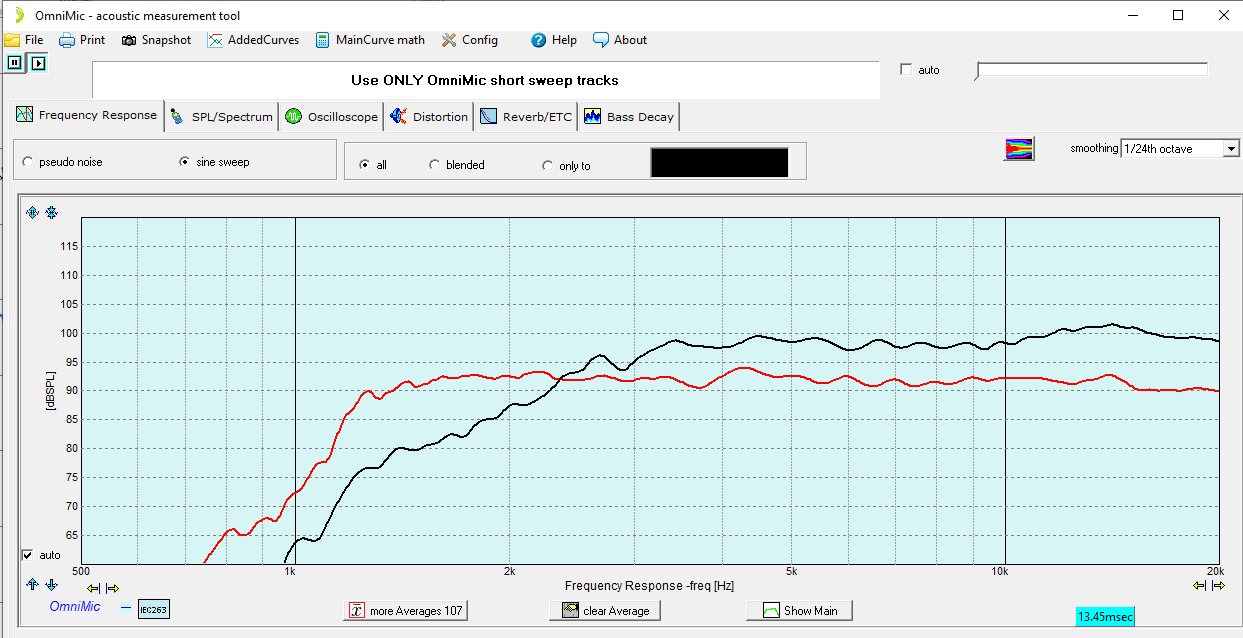

Before and after frequency response. Same drive level (approx 2.82V RMS), same setup, mic distance, location,placement. Just from one day to the next after installing the modified diaphragm into the same AMT tweeter body. Tweeter is Hygeia RT-5002. Response is pretty much identical for all practical purposes. On the after (red) I forgot to raise the HPF on the dbx 234xs to 1000Hz though. I believe that is why it is showing just a hair more output below 2k.

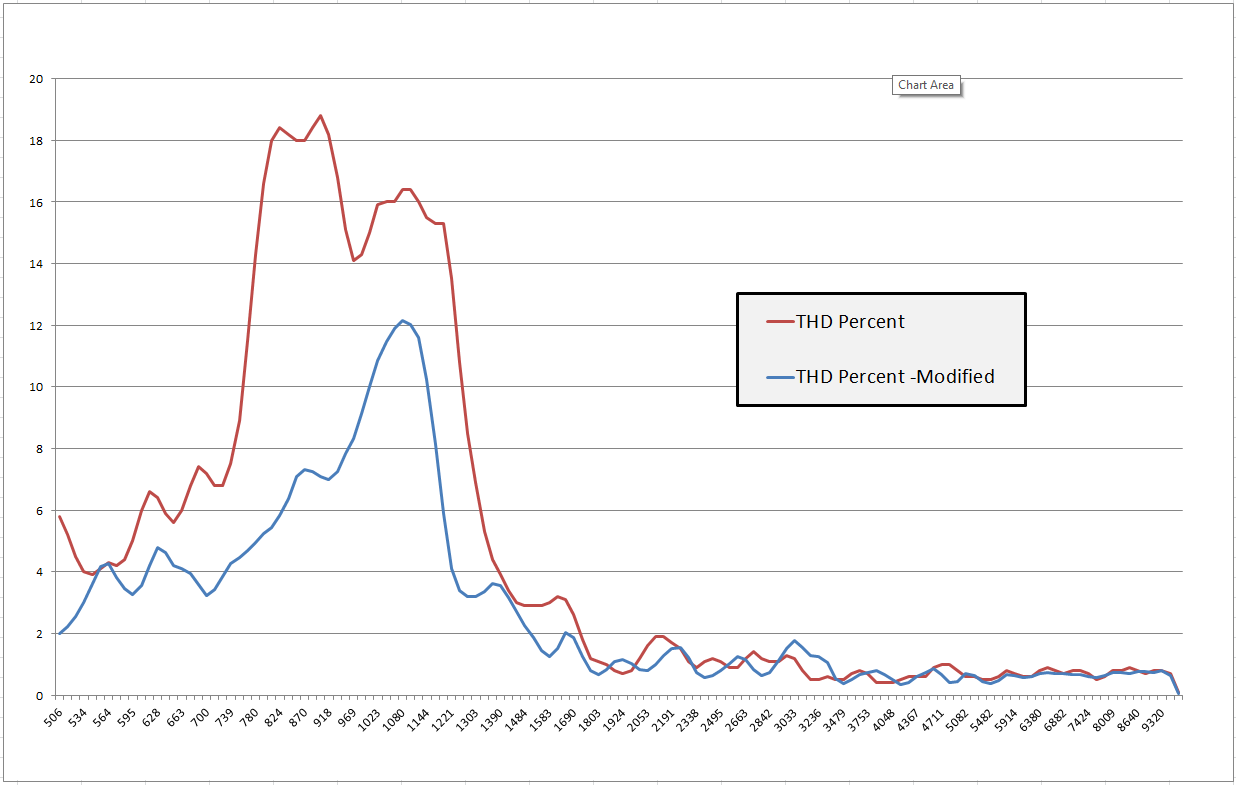

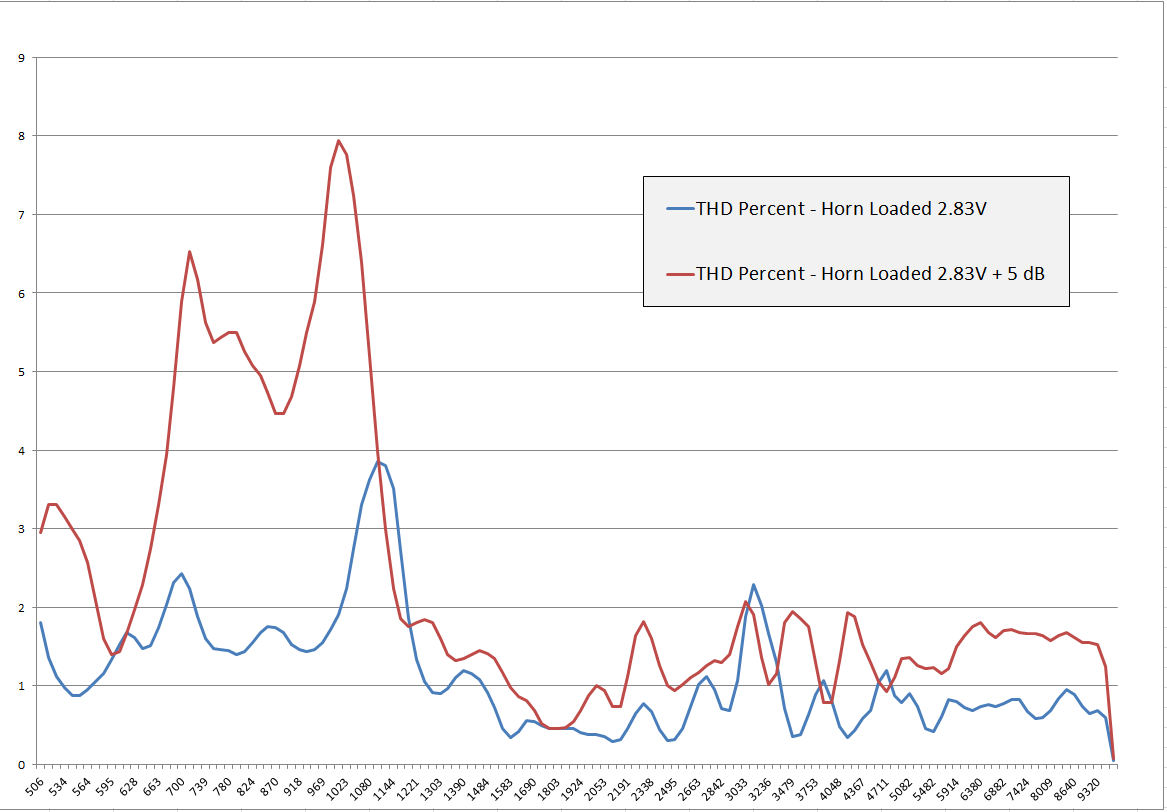

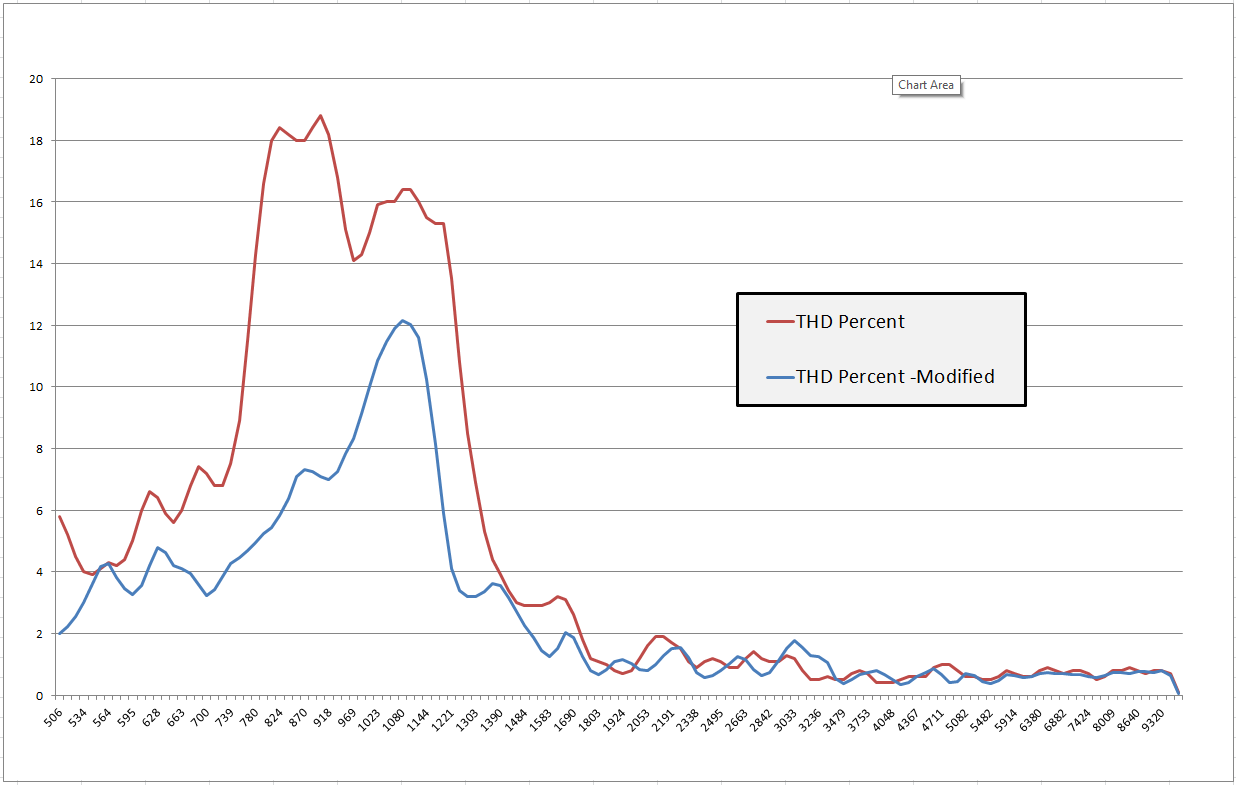

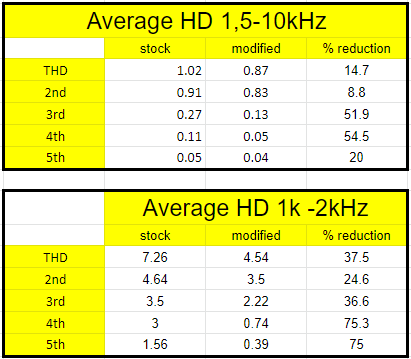

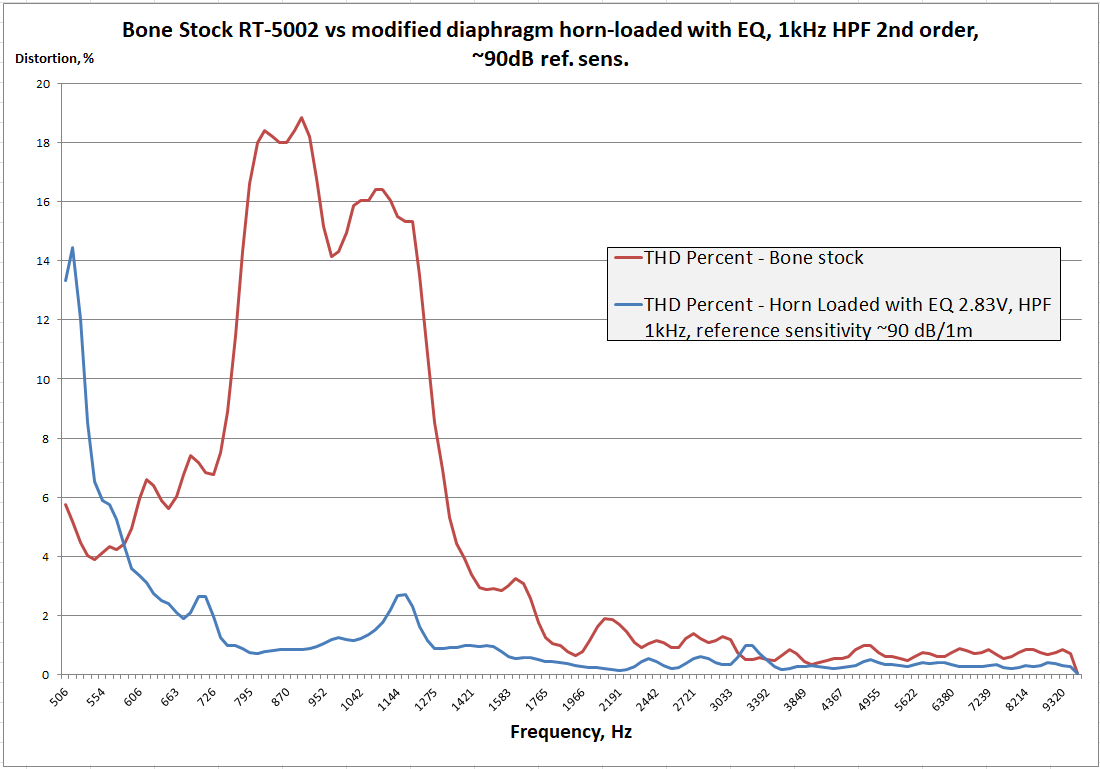

Here is the harmonic distortion data, before & after diaphragm modification. I used slightly more drive level than in the FR graphs, but the same for both HD tests.

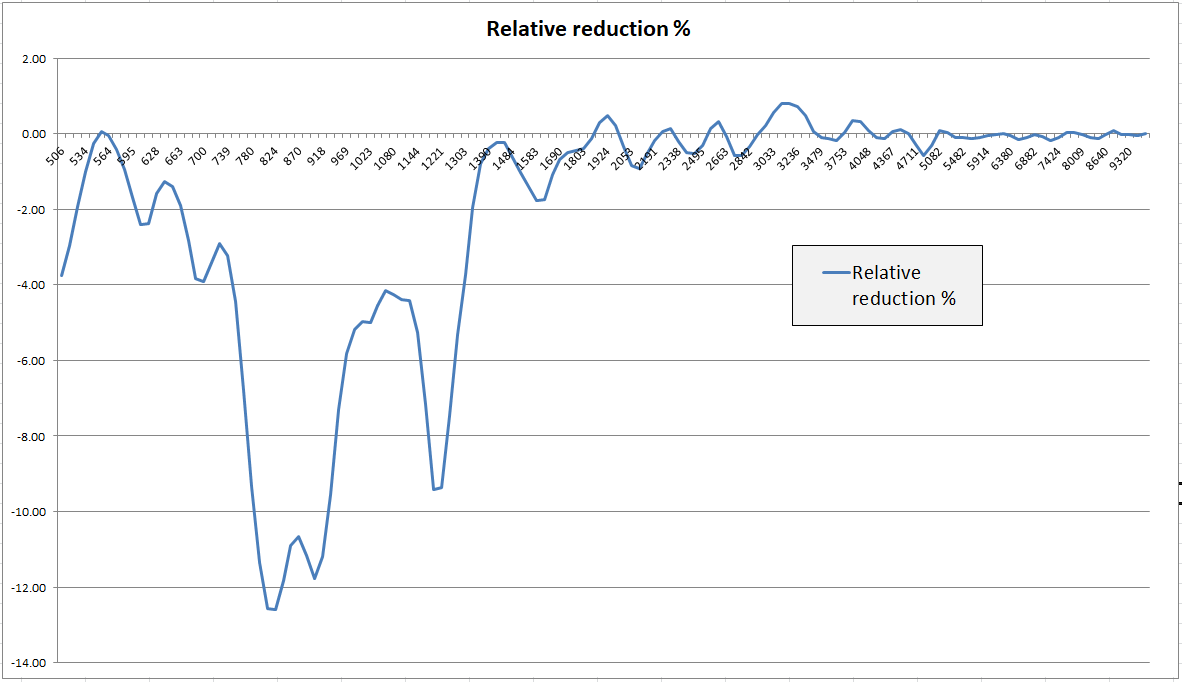

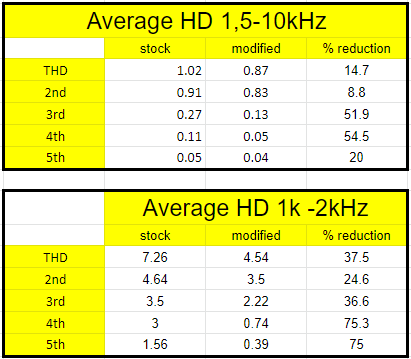

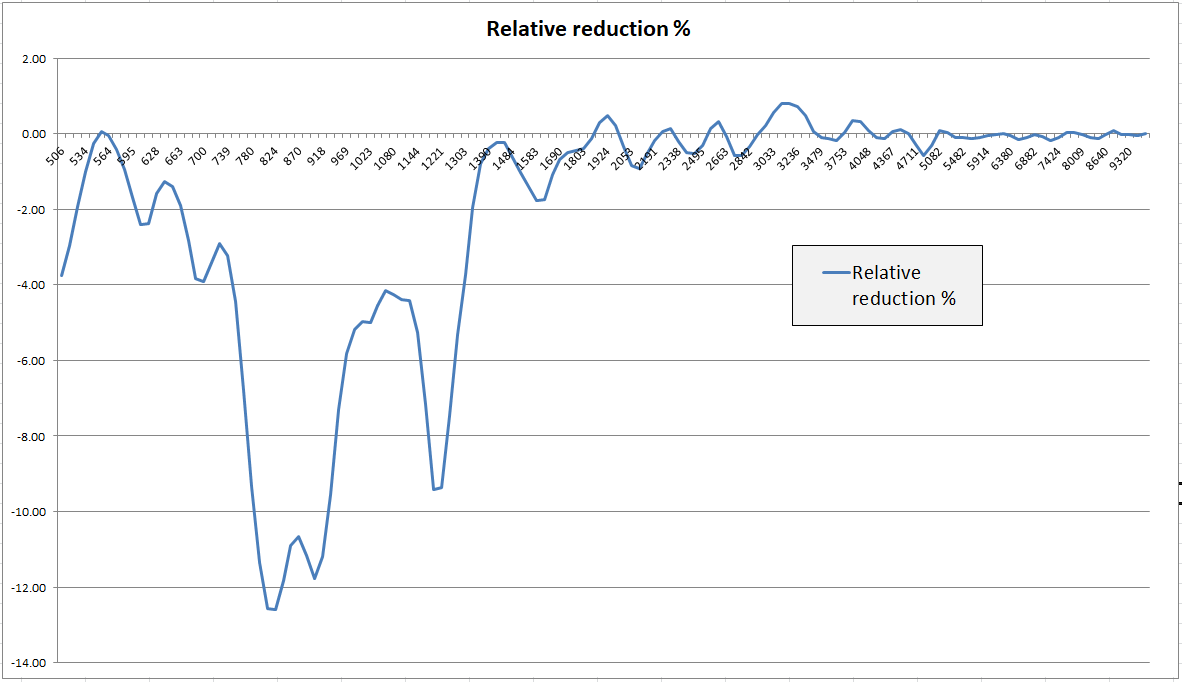

Doesn't look like much, but here is the quantitative data.

Conclusion:

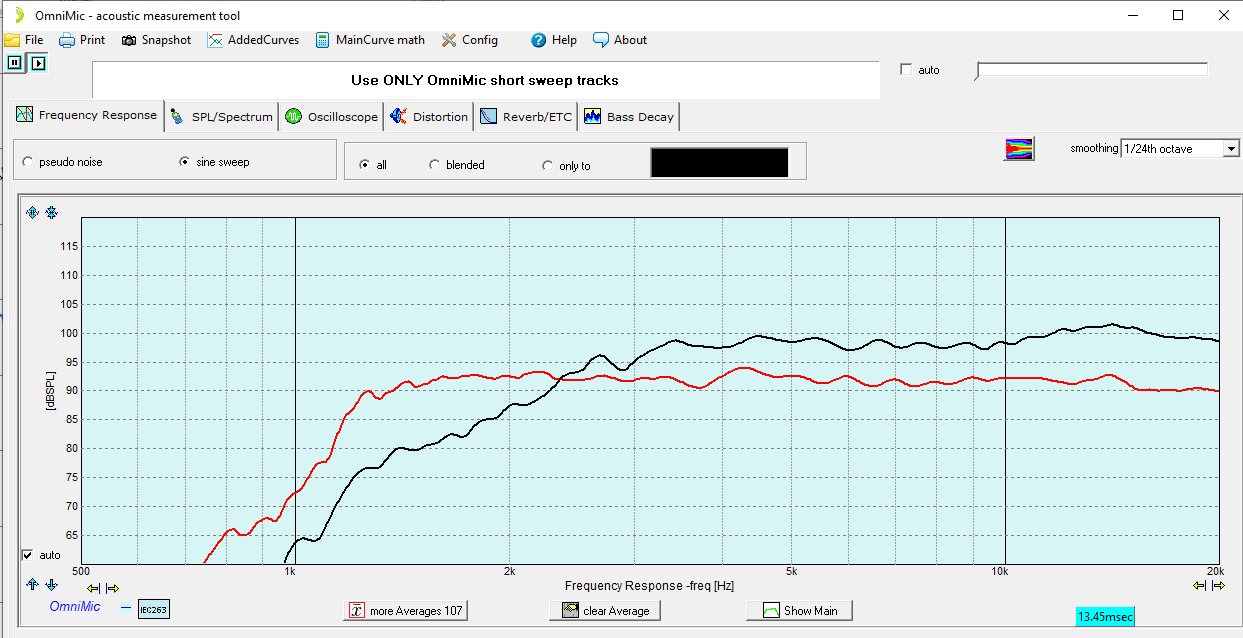

Modified RT-5002 with Dayton H110 horn.

~2.83V/1m, no EQ FR. Bone stock vs Horn loaded with modified Diaphragm.

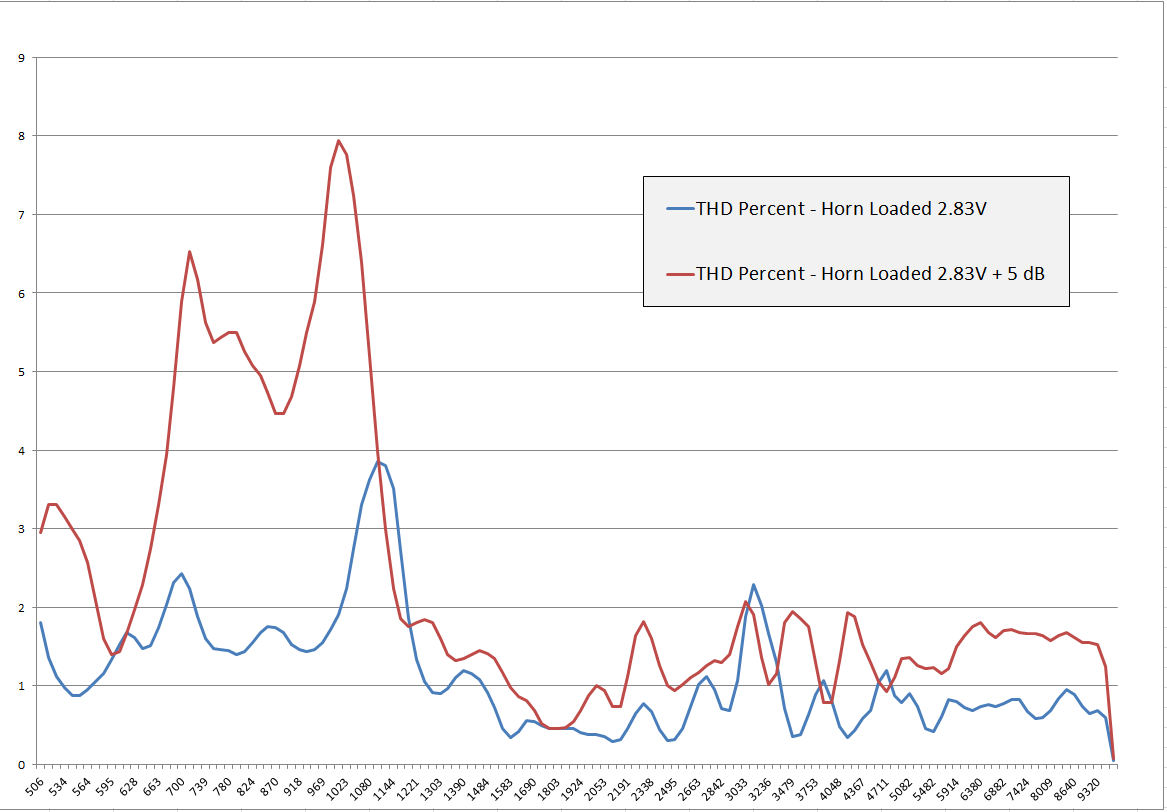

Harmonic Distortion, modified diaphragm, no EQ, 2.83V measured 10cm from horn. Also +5 dB.

Bone stock Frequency Response (black) vs modified diaphragm (red) with EQ, HPF ~1kHz.

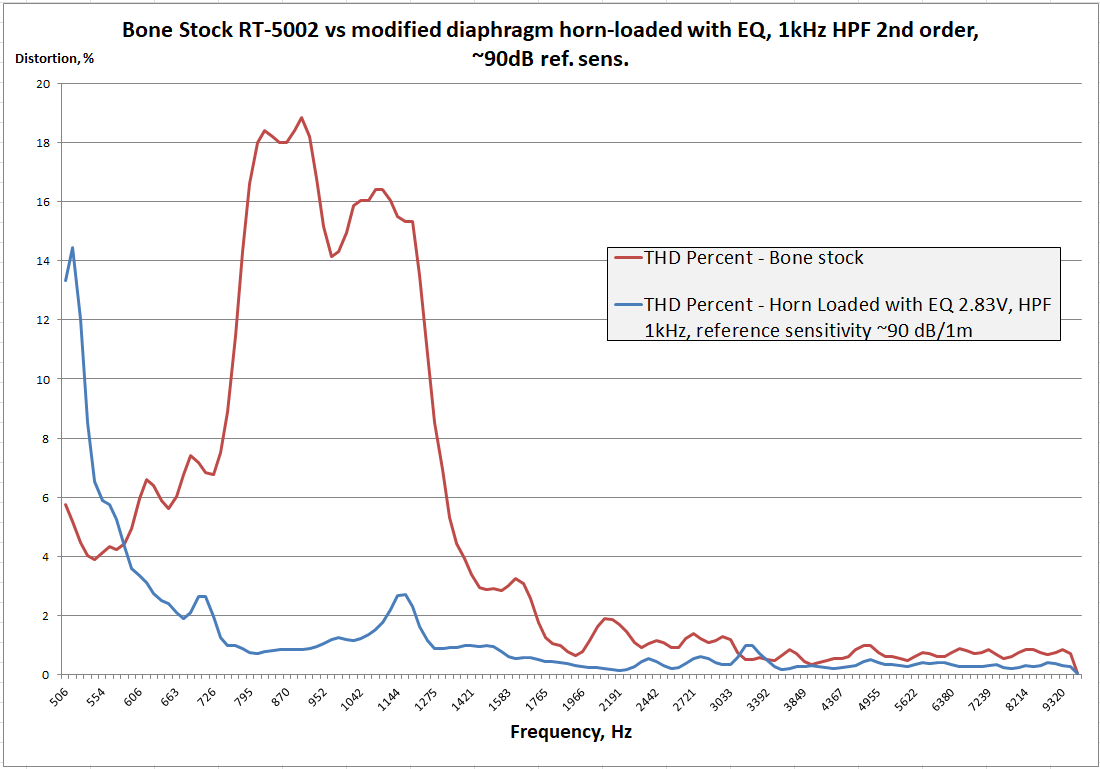

Harmonic Distortion, bone stock no EQ vs modified diaphragm horn-loaded with EQ, ~90 dB reference sensitivity.

The problem:

- The harmonic distortion (measured as a percentage to the fundamental) in one of my AMT tweeters rises as frequency goes down, hits a peak, but then lowers it's magnitude after passing the peak.

- on the lower-frequency range of the AMT driver, physical resonances end up propagating/traversing the diaphragm folds (in ways I have not yet visualized).

- To reduce the amplitude of these resonances, a viscoelastic compound could be applied to the diaphragm in small amounts, across the tops of the folds, to help absorb the energy of the resonances, thus damping them and the harmonic distortion associated with them.

- This leaves the pleats largely unaffected, and free to contract/expand normally.

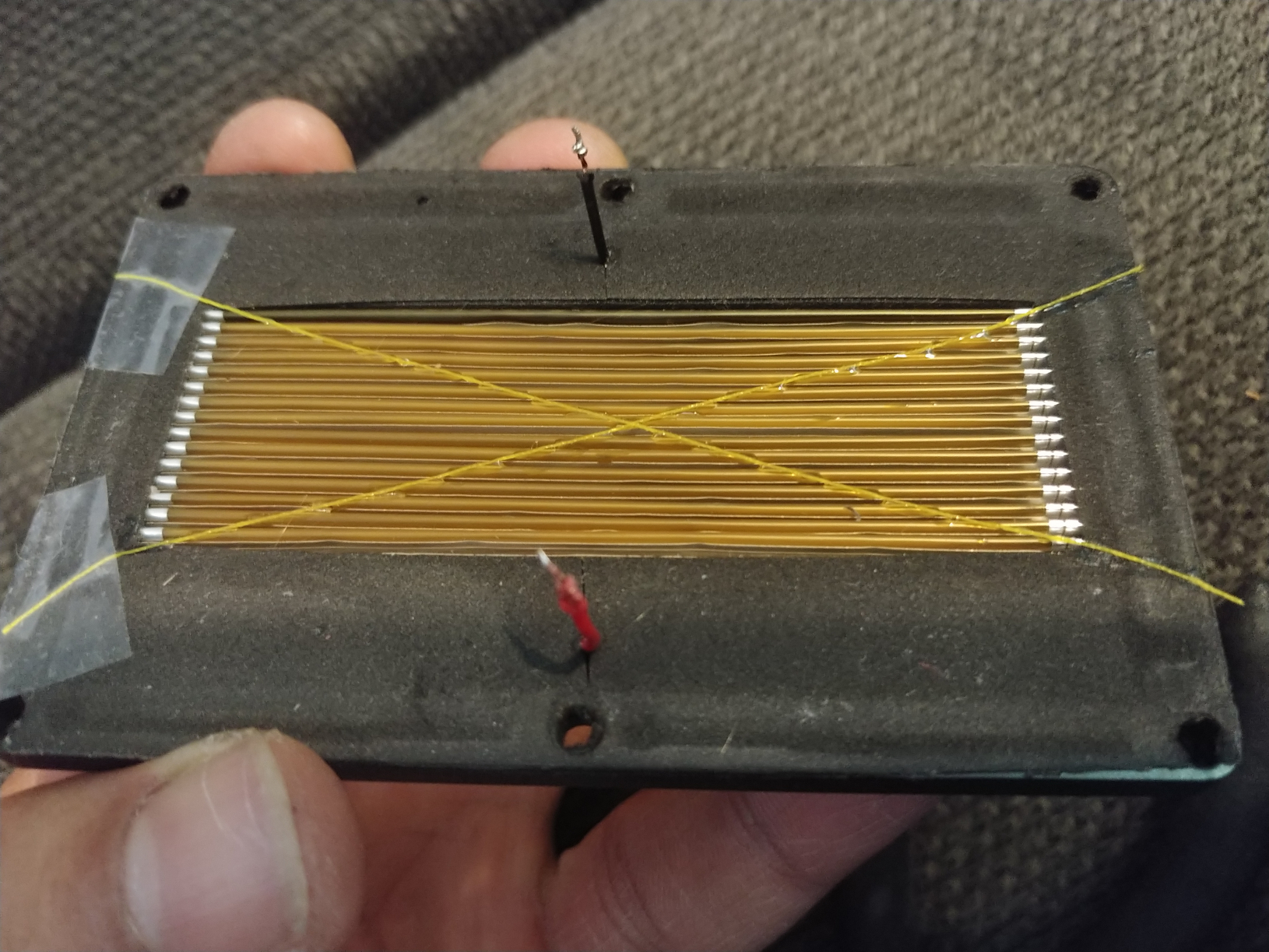

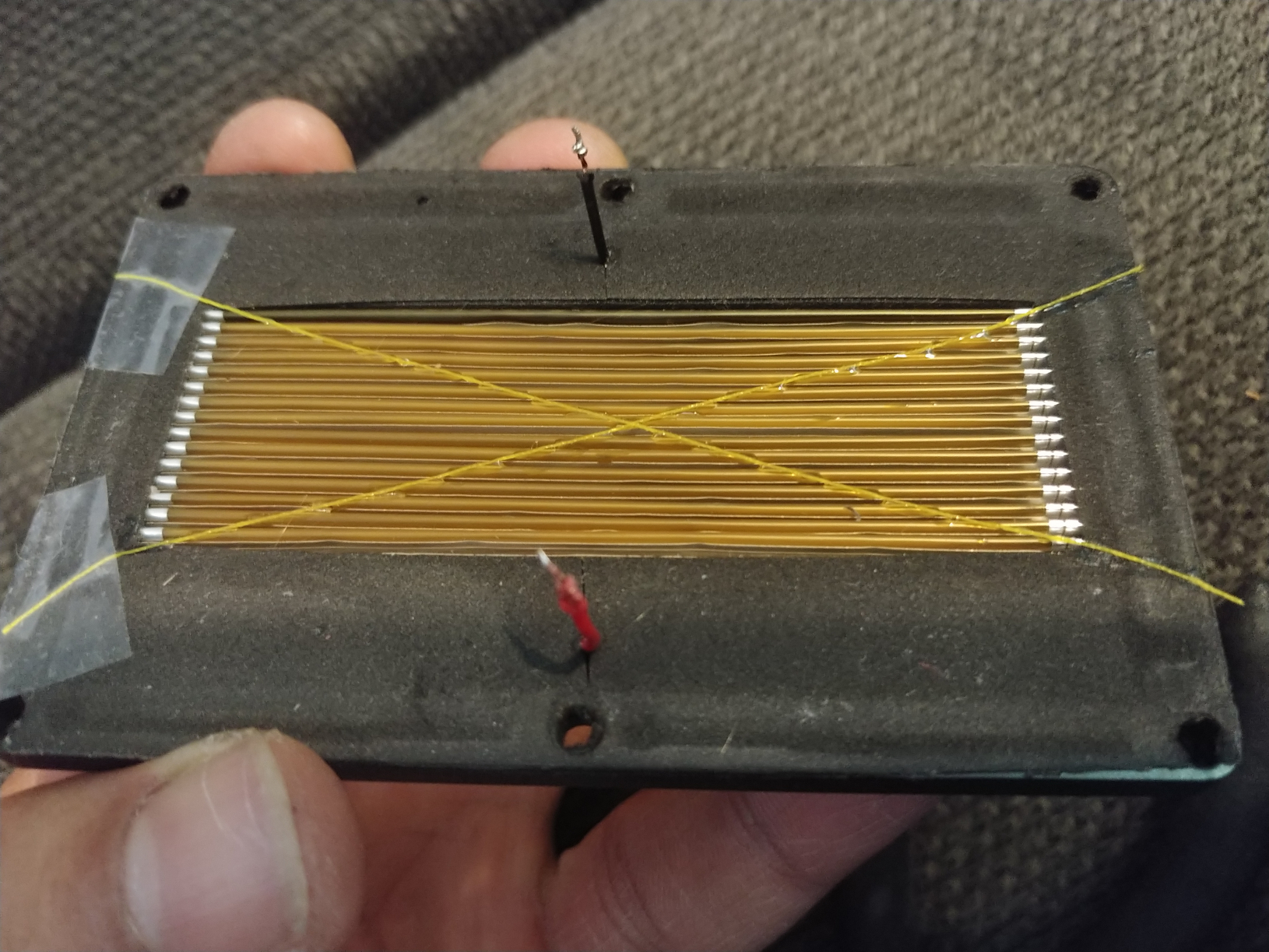

- use a brand new diaphragm and apply two thin threads to the back of the diaphragm, thinly coated with silicone sealant, across the tops of the folds, in an X-shape. Re-install and test under same conditions.

Before and after frequency response. Same drive level (approx 2.82V RMS), same setup, mic distance, location,placement. Just from one day to the next after installing the modified diaphragm into the same AMT tweeter body. Tweeter is Hygeia RT-5002. Response is pretty much identical for all practical purposes. On the after (red) I forgot to raise the HPF on the dbx 234xs to 1000Hz though. I believe that is why it is showing just a hair more output below 2k.

Here is the harmonic distortion data, before & after diaphragm modification. I used slightly more drive level than in the FR graphs, but the same for both HD tests.

Doesn't look like much, but here is the quantitative data.

Conclusion:

- I "used up" one spare diaphragm in the process, but I do not feel it was a waste.

- Further tests will include different orientations of the silicone treated thread across the diaphragm folds, both on the rear and also on the front.

- For my purposes, it works out well since I am looking to mate an AMT tweeter (not necessarily this one) to a 10" midbass driver, using a large horn, so obtaining the best possible low-end extension and performance is a primary objective. I used this diaphragm/tweeter as the test piece because it was relatively cheap.

- I suspect other larger [rectangular] diaphragms also suffer from un-necessary harmonic distortion content as a consequence of physical resonances traveling along the folds, and treating them in a similar fashion would also decrease distortion as a whole.

- I also slightly suspect that square diaphragms might also suffer from resonances, but to a much lower degree.

- There is an increase in THD near 3,2 kHz. Hopefully with more trial-and-error, that HD peak can also be tamed. Time to use up more spare diaphragms.

Modified RT-5002 with Dayton H110 horn.

~2.83V/1m, no EQ FR. Bone stock vs Horn loaded with modified Diaphragm.

Harmonic Distortion, modified diaphragm, no EQ, 2.83V measured 10cm from horn. Also +5 dB.

Bone stock Frequency Response (black) vs modified diaphragm (red) with EQ, HPF ~1kHz.

Harmonic Distortion, bone stock no EQ vs modified diaphragm horn-loaded with EQ, ~90 dB reference sensitivity.

Comments

Now go back to the future, lol, to March of this year when I was on Spring Break from my work. I ended up testing the FR of the damaged diaphragms, and surprisingly the FR was almost back to normal. Then the kicker was when I decided to see "how bad" the distortion increased, and surprisingly, the top end seemed almost as good as new, but the low-end had decreased! When I say low I mean from about 1000-2,500 Hz. So I begun my gedankenexperiment. I always had a hunch that the HD spike in the 1,3kHz was due to a resonance. Then I remembered looking at this video from the DIY AMT thread on diyaudio.com. In that video series you can see how even though in theory of operation only the parallel pleats are supposed to move towards/away from each other during normal AMT operation, the tops of the folds also end up vibrating themselves as well, and start to move sideways (exaggerated in that video by purposely driving the diaphragm to the point of non-linear behavior). Just like a rod suspended between two points; short enough and it shouldn't wobble too much from external excitation, but if you make it long enough, it ends up being like a guitar string where it will have it's own resonances/harmonic frequencies. In the case of the damaged diaphragms, the imperfect nature of the now curved pleats is what I felt was curbing the natural resonance that had caused the HD spike near 1,3 kHz. I felt that the non-linear behavior in the video also applied to this AMT diaphragm since it was longer in one dimension than the other. Not only that, the more homogeneous a system is, the easier it is to excite a resonance within it, in the absence of damping. In my mind it was like a normal cone transducer having only one centering suspension (surround or spider) to center the whole moving assembly (in the AMT this would be the outside perimeter equivalent to one centering suspension). But without a 2nd centering suspension, the voice coil in a cone transducer will have more degrees of freedom with regards to rocking around. What was "missing" from the AMT diaphragm was it's own "spider" to "keep things centered" (ie: removing a degree of freedom, aka the tops/bottom of the folds immobilized, that is). Keeping a voice coil in a cone transducer centered with a dual suspension system is the parallel of maintaining the AMT folds from having that extra degree of freedom and allowing that non-linear behavior. That way, if the peaks/troughs of the folds could be "held" so that they don't move, the pleats themselves will be the only things moving, as they should be, which should lead to lower distortion. I chose sewing thread because it had to be something lightweight and easy to apply. Silicone was chosen because it is readily available and stays somewhat flexible after it has cured. That was my answer to the question: How can I reduce the excitability of the hypothesized resonance without going as far as randomly bending the pleats around like the damaged diaphragms are?

I actually expected to loose some sensitivity, and there was a little on the last octave, but I reckoned that since the tops of the folds weren't supposed to move anyways, the silicone'd sewing thread which is extremely thin is not going to interfere with the conductive pleats that are supposed to be [slightly] moving and creating sound. The pleats themselves shouldn't be moving all that much anyways, under normal operation, so something "grabbing" to the tops of the folds shouldn't phase them either. I'm only holding immobile what is already supposed to be immobile.

How are you fastening the siliconed thread to the tops of the diaphragm?

You might be able use a weak glue for the test(s) and then take off the thread and return the TPL-150 to (hopefully) stock.

IMO the value is creating something from nothing, what can you do with the HiVi and Bestons?

I'm now wondering what the distortion mode is for a bunch of other drivers...

On a different note, going back on some previous measurements of mine, I need to stop using this class-D amp for distortion measurements, as they sure did come out lower when I was using a class A/B amp with an even higher drive level!

For planar ribbons, it would be much trickier, IMO. The disadvantage lies in the fact that if there are spurious, unwanted resonances traveling up & down the diaphragms, to tame them would be to dampen & constrain the planar diaphragm in the direction of travel (front to back), which would then adversely affect FR and/or sensitivity. In the AMT scenario, the direction of back-and-forth motion of the pleats/traces is perpendicular to the edges of the folds, so it causes little to no restraint of motion.

Perhaps this is a job for Mundorf Angel Hair (treating planar ribbons).

Looks like they developed a new AMT as well, looks to be larger than the 4001, but smaller than the 5002:

I think I might order a few of these to play with as well.

I also asked if there was any possibility of them producing a mega AMT like the big Beyma's or the Aurum Cantus AST's, or the Dayton AMTPRO-4. Let's see what they say.

InDIYana Event Website

InDIYana Event Website

You'd be able to see it in-person, but not here. Crossing my fingers it works.

be interested.

Oh, and I'm also gonna see if I can twin-stack AMT's to make Super-AMT's, lol. Sort of making a cheap "Beyma-killer". I noticed that in the RT-5002, there is some "dead space" (non-magnetic) above (&below) the magnet array that is seemingly there because of the size of the cartridge that is the diaphragm. I'm going to eventually put two in my mill to shave off the tops to merge them vertically. I'll have to modify the rest of the steel plates, but that's eazy peazy on a milling machine with some high speed steel endmills.

Something like this:

That's about as close as you can get them without messing with the folds themselves. The separation distance would be about ½" between the actual moving folds. Imagine that sucker horn-loaded with some good compression! Betcha it can get low.

I'm trying to fix my original modified one with the thread, since the tiny lead wires have all but broken off. If I can get it working, I will test the three back-to-back. Well four when I re-do the diaphragm that I smoked.