Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

Please review the site Rules, Terms of Service, and Privacy Policy at your convenience. Rules, TOS, Privacy

Get familiar with the reaction system: Introducing the Reaction System

New Seas 27TAC/GB, some facts, some opinions, and some data...

I recently purchased a pair of these from Meniscus. They are not on their website yet. I e-mailed my inquiry. Mark hooked me up.

Seas website blurbs:

http://www.seas.no/index.php?option=com_content&view=article&id=561:prestige-titan-launch-news&catid=41:news&Itemid=194

http://www.seas.no/index.php?option=com_content&view=article&id=556:h1825-06-27tac_gb&catid=45:seas-prestige-tweeters&Itemid=462

Here is the retail price and info on MAD, just for more information:

https://www.madisoundspeakerstore.com/hard-dome-tweeter/seas-prestige-27tac/gb-h1825-aluminum/magnesium-dome-tweeter/

It supposedly is simply an improved 27TBFC. Copper cap where there was not one before, titanium (Titan line) voice coil former, a reshaped and carefully damped chamber, as well as being shipped/sold in matched pairs. I'll admit, the $91 price tag seems a bit high for production with a glass-reinforced plastic faceplate, but truth is you don't find titanium formers in very many drivers that cost less than $100. Normally they are aluminum, glass fiber, or Kapton. Seas uses a Corian material in their diamond line tweeters, so maybe they don't use metal faces often either. (I see Excel units are cast faces) The faceplate is really thick when it comes down to having plastic faces of any sort, along with what appears to be a metal hexagrid. The chamber cup and integrated divot remind me of those in the DX/XT line from Peerless, basically a sinusoidal curve of Pi length rotated around the Y axis. It's not quite a half-torus shape. Being that the TBFC is a bit splashy, and these have a copper cap to reduce HD, that is what tickled my fancy. More on the tweeter choice will come when I start posting info about the design path.

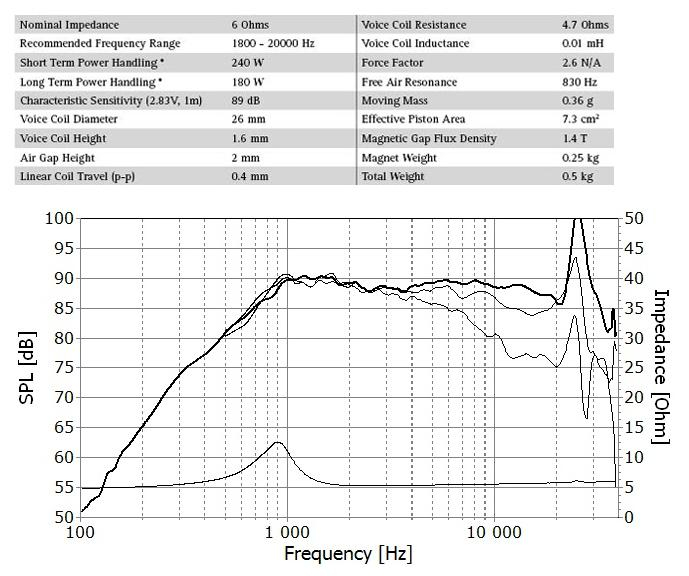

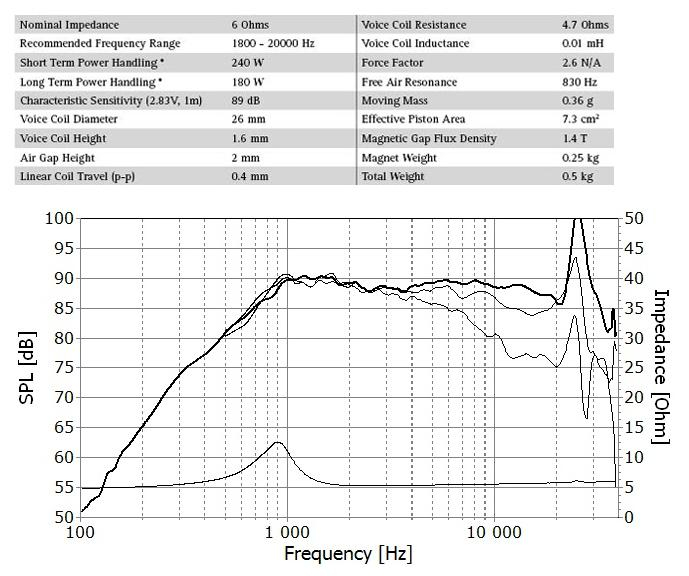

My first run-ins on the trusty ol' S&L WT2 left me perplexed, as this is the spec sheet info:

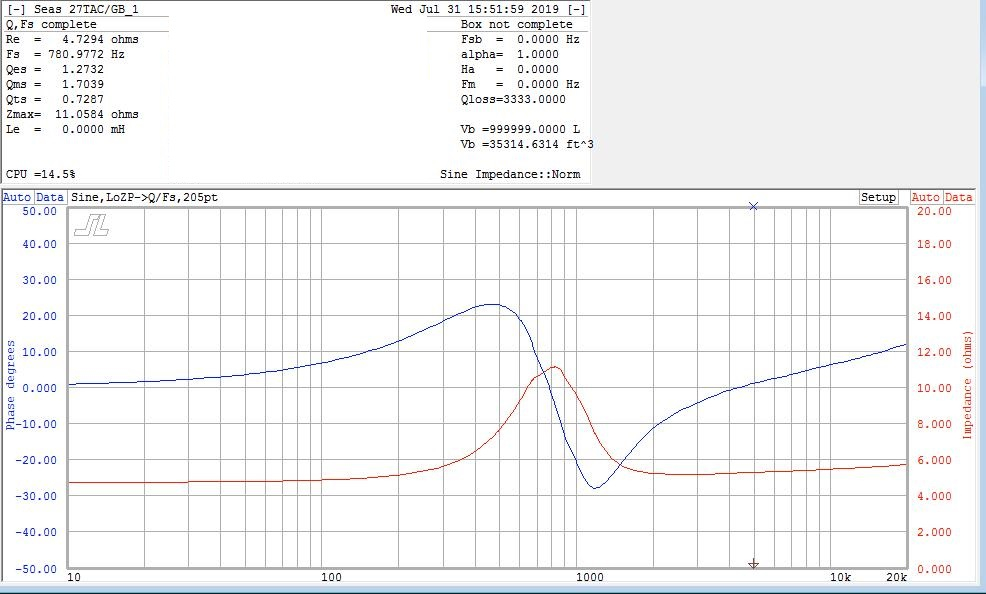

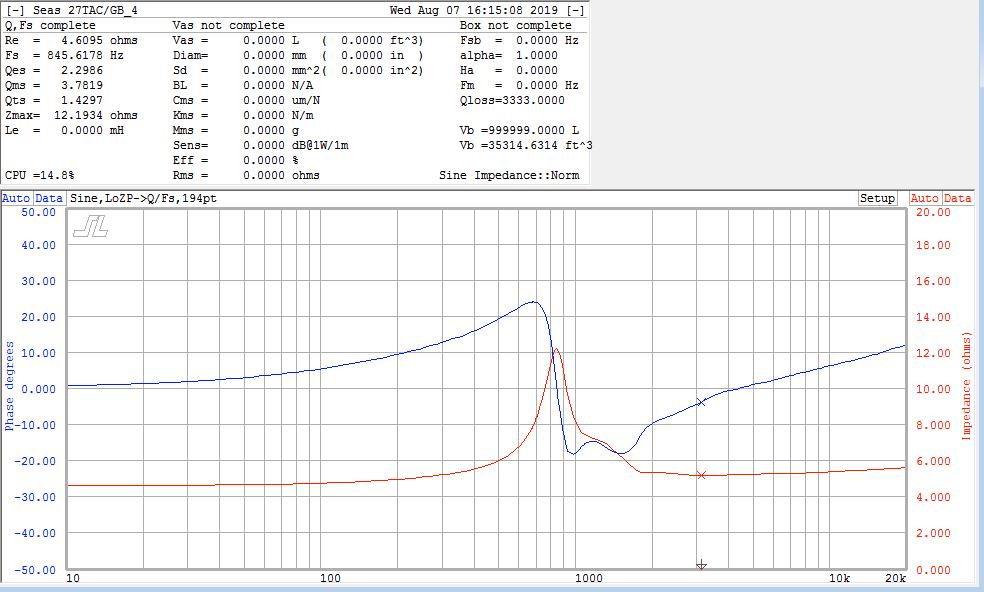

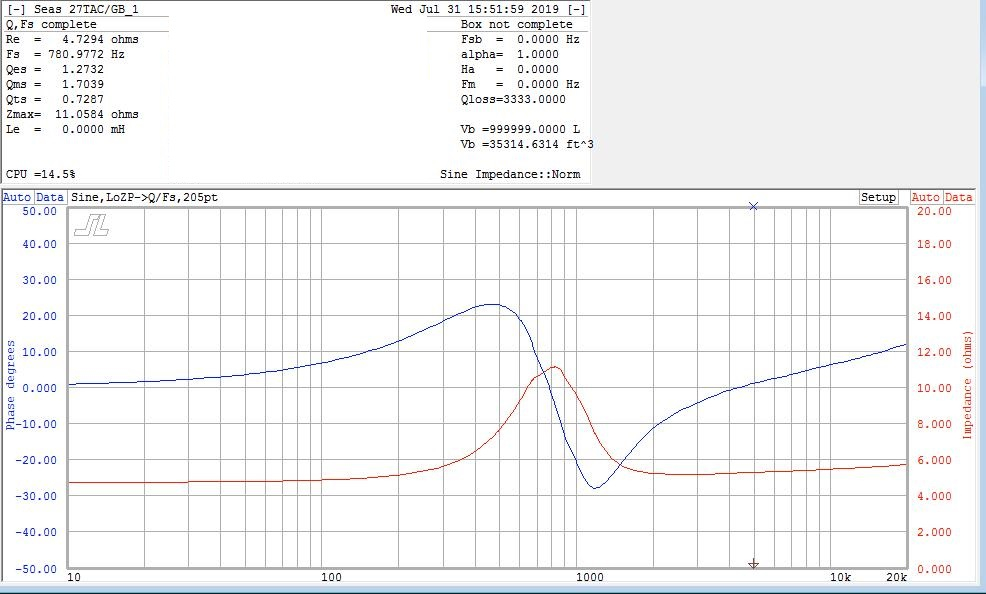

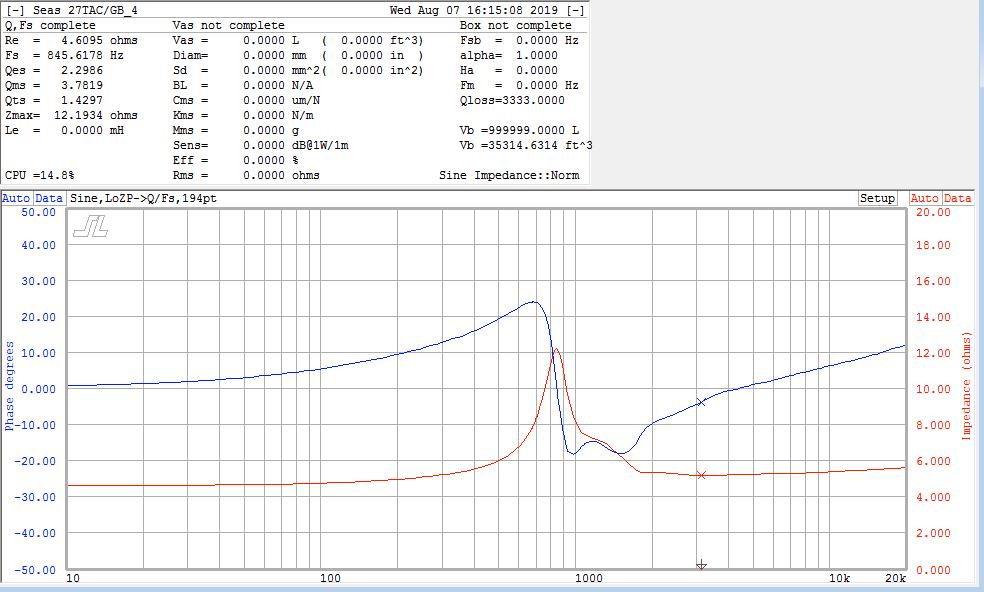

I see the spec sheet as 900 Hz and 13 ohms, not 830 Hz as listed. And these are what I got:

The second one has a higher magnitude, but otherwise looks to be normal. Obviously, I would not call these a matched pair were it my judging. Mark said he noticed that as well, as he had measured them before he shipped them out and wondered if I would also raise an eyebrow. So- he shipped me another pair, with one that matched #2 above rather well, and another that appeared to be a bit 'off the mark'. I'm a bit disappointed in Seas for having these sold as a matched pair, and that there was this much discrepancy in a $180 pair of tweeters. I would think that this much shift would be unheard of at this price point.

He also said they will be QCing drivers for better matching tweeters, etc, and including the DATS T/S runs on a nice sticker that you can slap on the driver magnet. The sample stickers I got look pretty cool. I don't know if this will be an offered service, or if this is something that they will be doing per order as they come for free. You'll have to contact Mark about that. Either way, I as pleased I was able to get a matched pair through their diligence. He let me keep and tear into the other pair that weren't as accurate as I saw fit.

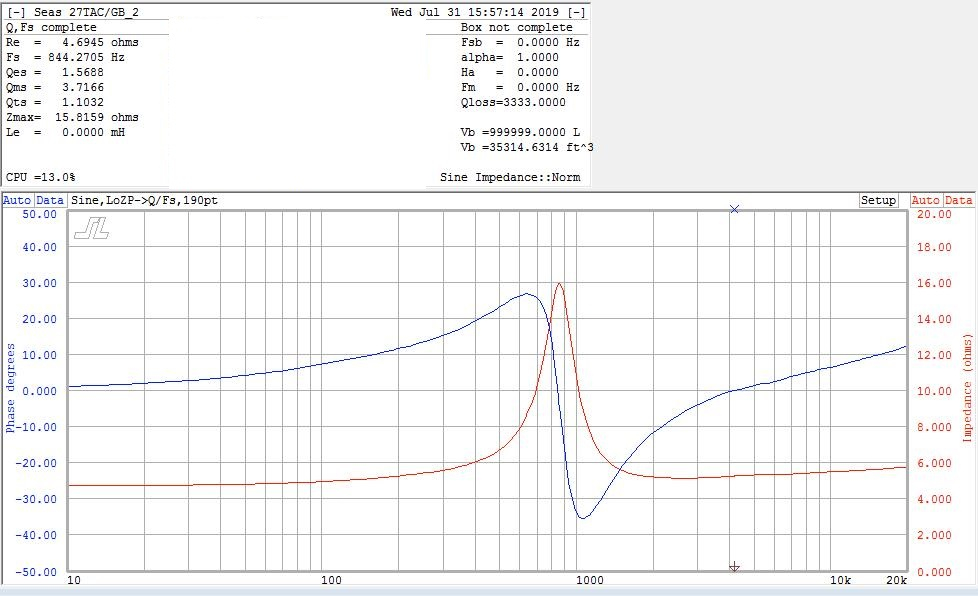

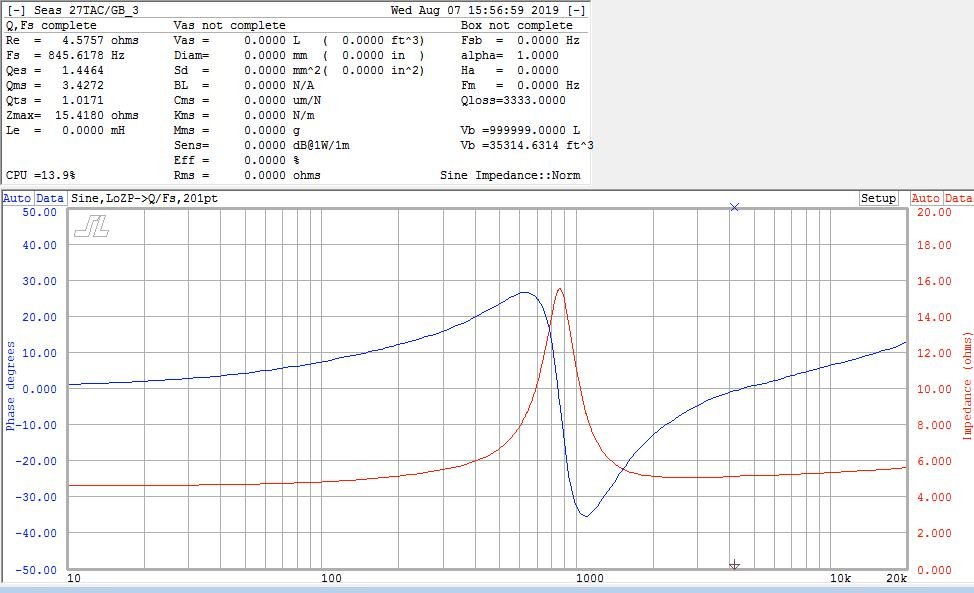

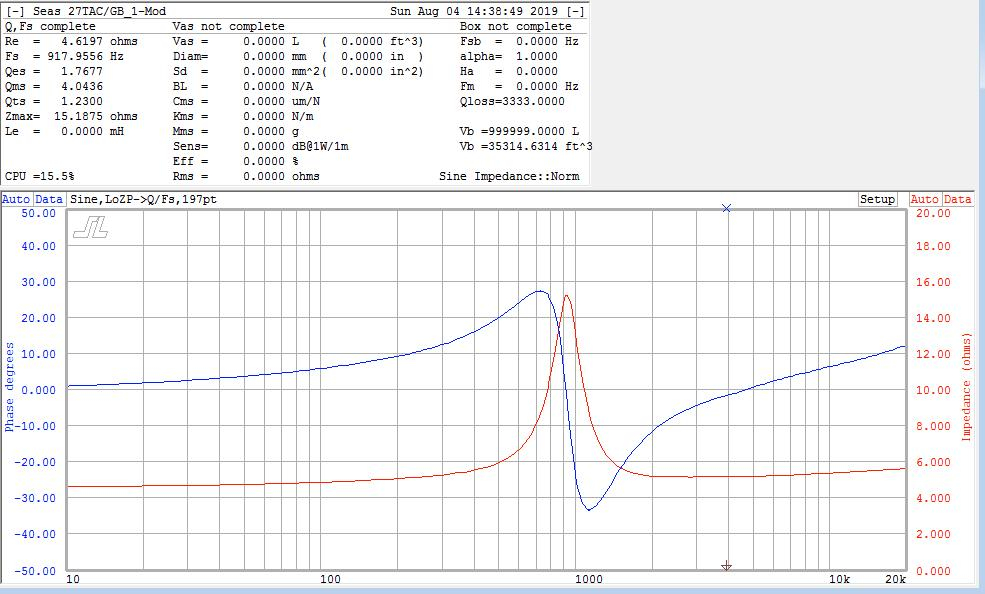

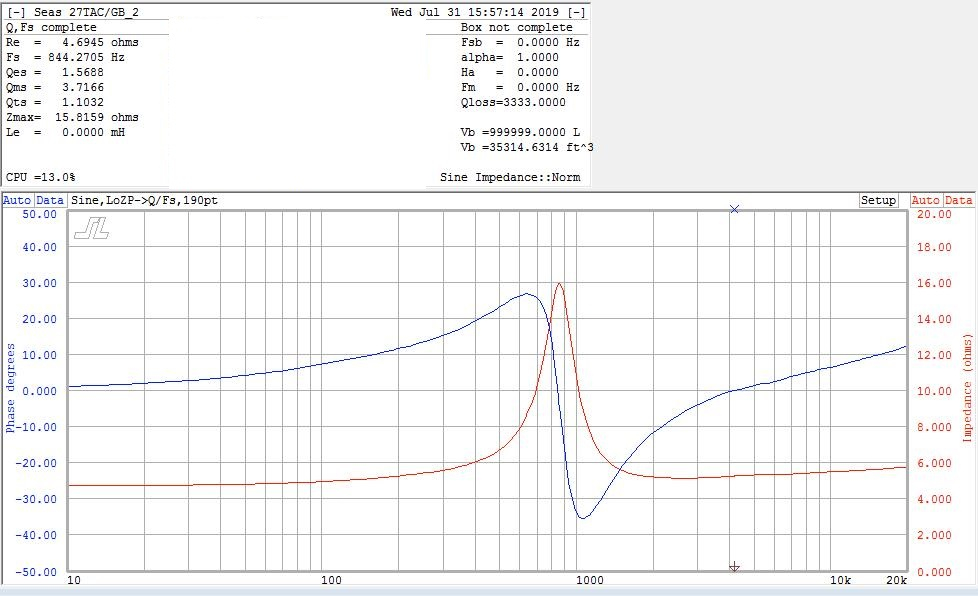

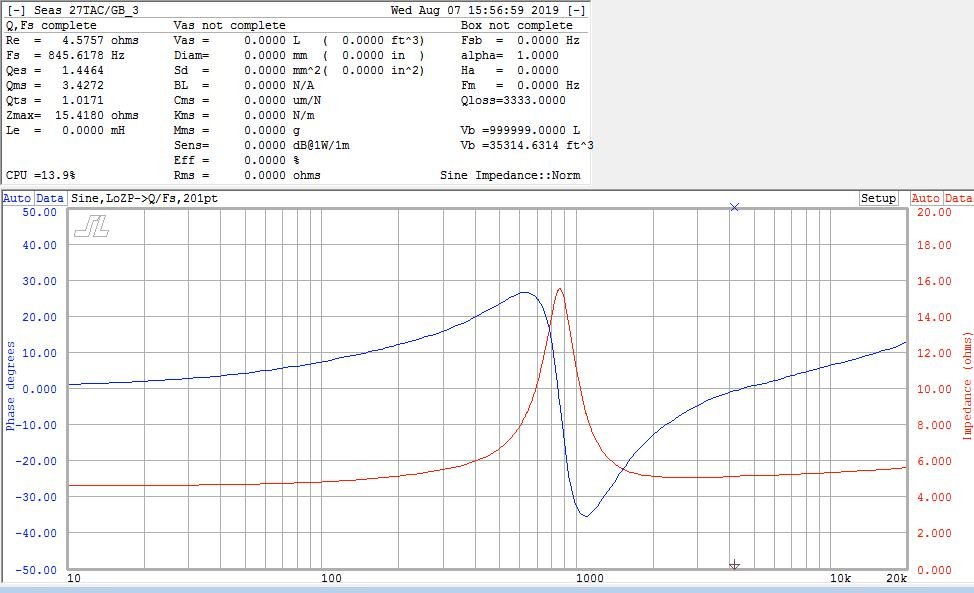

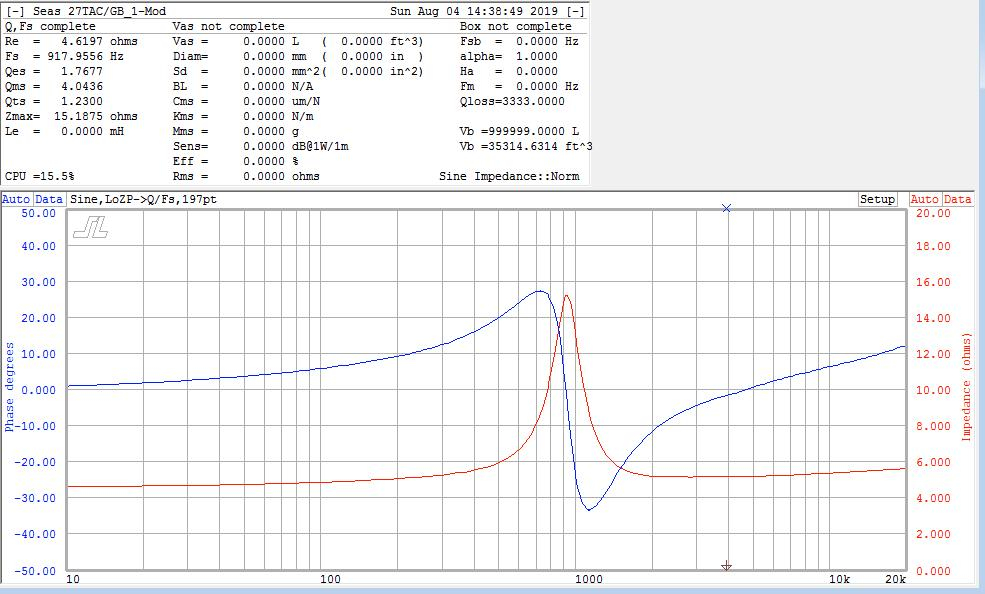

Here are the measured data of the second set:

Number 2 and 3 overlay with only about a half-ohm magnitude difference at resonance, and the T/S are really similar as well. I imagine these will be really close over all.

Being the recent practice I and others have had at adjusting the tweeters' specs, I used Bill's method of a putty knife prying up around the surface to loosen and remove the cap. This worked really well for these 2 tweeters, and I didn't have to saw a gap first as the knife fit between without adjustment.

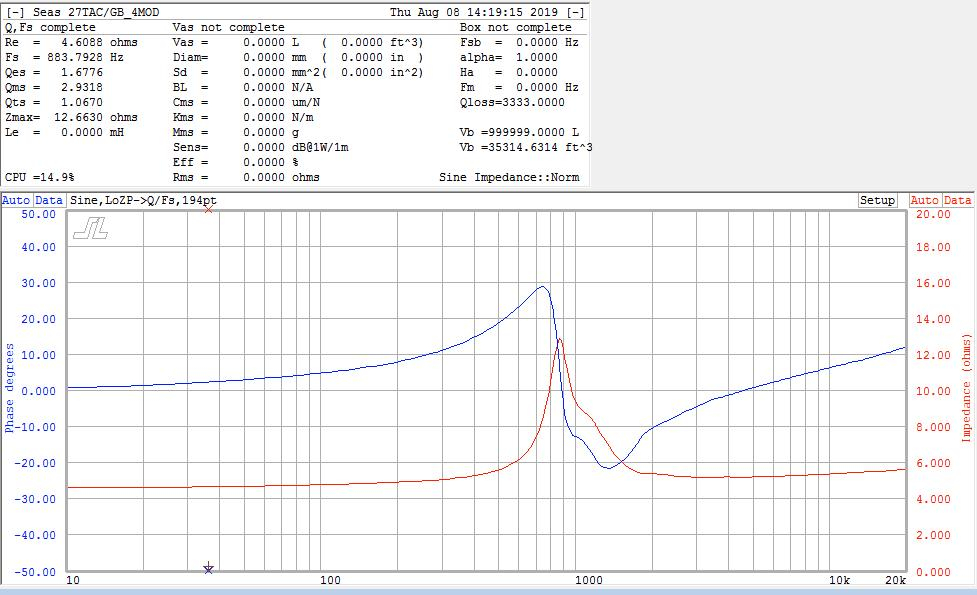

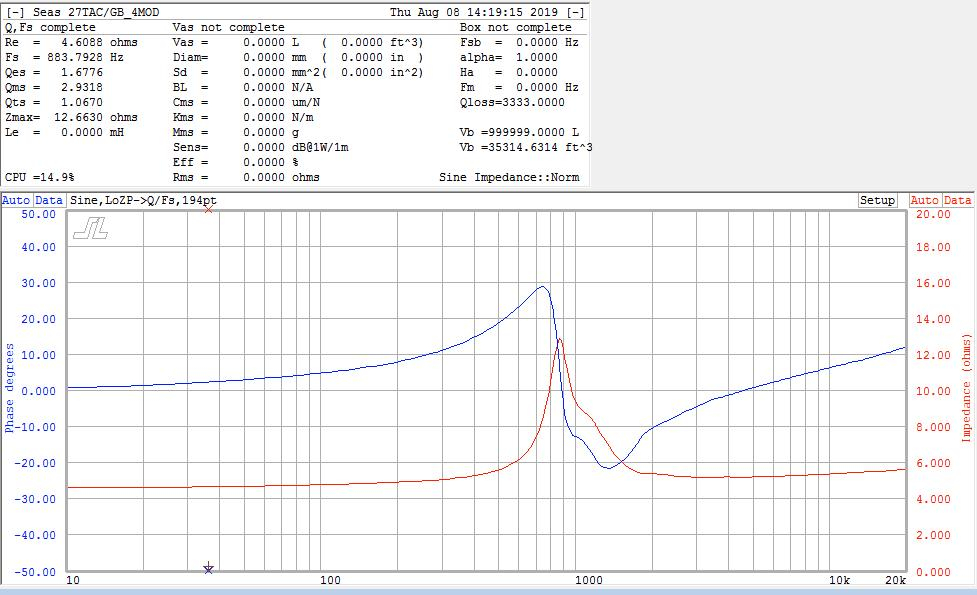

First subject, #1, had about a 1" cotton ball wedged between the inner side of the divot and the vented pole piece in the magnet. That was all it had behind the magnet. There is also a felt ring atop the pole, which is generally a good addition in terms of FR. As in my normal tweeter adjustment MO, I gently inserted this into the pole-hole, and added about a 1.5" square of Ultratouch 1" thick. Then I glued the cap back on with E6000 and awaited cure for remeasurement. This was the result:

The Q parameters were a bit higher, as was the Fs, but this is a lot closer to spec than it was. I would even call this within tolerance compared to the 'approved' pair.

Tweeter #4 appeared like it would be additionally perplexing. The tangential sway above resonance from the typical roller-coaster impedance was a head-scratcher. I did the same mod to this unit as I did to #1, and resulted in this:

This had a shape that was more like the others. That 'sway from 1k to 1.8k was still there, albeit at a different magnitude. Well, I didn't think that tearing back into the rear and stuffing would change anything for the better, as it should look like the other 3 if that were the inherent cause. OK, time to remove the faceplate and see what I can observe...

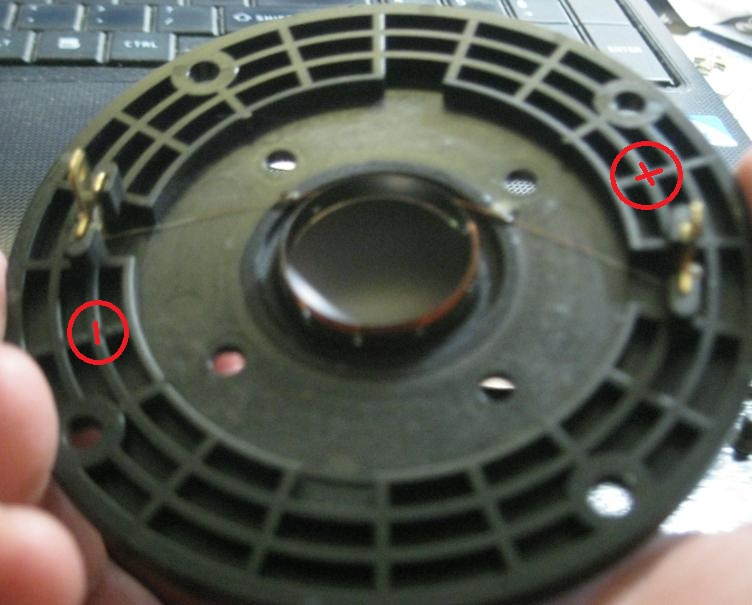

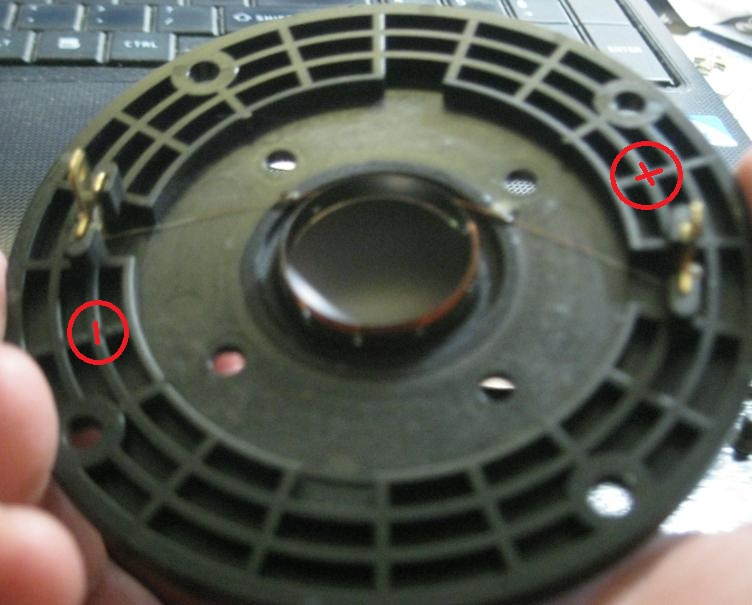

The surround is glued to the rear of the faceplate, so be careful if you remove the faceplate. Another note about the faceplate is that the polarity markers are really hard to find, and are on the structural cross-members. They are not on the terminals or the terminal supports, so I marked mine with a red Sharpie. They were also hard to see in the photo below, so they are enhanced for detail.

More in the next post...

Seas website blurbs:

http://www.seas.no/index.php?option=com_content&view=article&id=561:prestige-titan-launch-news&catid=41:news&Itemid=194

http://www.seas.no/index.php?option=com_content&view=article&id=556:h1825-06-27tac_gb&catid=45:seas-prestige-tweeters&Itemid=462

Here is the retail price and info on MAD, just for more information:

https://www.madisoundspeakerstore.com/hard-dome-tweeter/seas-prestige-27tac/gb-h1825-aluminum/magnesium-dome-tweeter/

It supposedly is simply an improved 27TBFC. Copper cap where there was not one before, titanium (Titan line) voice coil former, a reshaped and carefully damped chamber, as well as being shipped/sold in matched pairs. I'll admit, the $91 price tag seems a bit high for production with a glass-reinforced plastic faceplate, but truth is you don't find titanium formers in very many drivers that cost less than $100. Normally they are aluminum, glass fiber, or Kapton. Seas uses a Corian material in their diamond line tweeters, so maybe they don't use metal faces often either. (I see Excel units are cast faces) The faceplate is really thick when it comes down to having plastic faces of any sort, along with what appears to be a metal hexagrid. The chamber cup and integrated divot remind me of those in the DX/XT line from Peerless, basically a sinusoidal curve of Pi length rotated around the Y axis. It's not quite a half-torus shape. Being that the TBFC is a bit splashy, and these have a copper cap to reduce HD, that is what tickled my fancy. More on the tweeter choice will come when I start posting info about the design path.

My first run-ins on the trusty ol' S&L WT2 left me perplexed, as this is the spec sheet info:

I see the spec sheet as 900 Hz and 13 ohms, not 830 Hz as listed. And these are what I got:

The second one has a higher magnitude, but otherwise looks to be normal. Obviously, I would not call these a matched pair were it my judging. Mark said he noticed that as well, as he had measured them before he shipped them out and wondered if I would also raise an eyebrow. So- he shipped me another pair, with one that matched #2 above rather well, and another that appeared to be a bit 'off the mark'. I'm a bit disappointed in Seas for having these sold as a matched pair, and that there was this much discrepancy in a $180 pair of tweeters. I would think that this much shift would be unheard of at this price point.

He also said they will be QCing drivers for better matching tweeters, etc, and including the DATS T/S runs on a nice sticker that you can slap on the driver magnet. The sample stickers I got look pretty cool. I don't know if this will be an offered service, or if this is something that they will be doing per order as they come for free. You'll have to contact Mark about that. Either way, I as pleased I was able to get a matched pair through their diligence. He let me keep and tear into the other pair that weren't as accurate as I saw fit.

Here are the measured data of the second set:

Number 2 and 3 overlay with only about a half-ohm magnitude difference at resonance, and the T/S are really similar as well. I imagine these will be really close over all.

Being the recent practice I and others have had at adjusting the tweeters' specs, I used Bill's method of a putty knife prying up around the surface to loosen and remove the cap. This worked really well for these 2 tweeters, and I didn't have to saw a gap first as the knife fit between without adjustment.

First subject, #1, had about a 1" cotton ball wedged between the inner side of the divot and the vented pole piece in the magnet. That was all it had behind the magnet. There is also a felt ring atop the pole, which is generally a good addition in terms of FR. As in my normal tweeter adjustment MO, I gently inserted this into the pole-hole, and added about a 1.5" square of Ultratouch 1" thick. Then I glued the cap back on with E6000 and awaited cure for remeasurement. This was the result:

The Q parameters were a bit higher, as was the Fs, but this is a lot closer to spec than it was. I would even call this within tolerance compared to the 'approved' pair.

Tweeter #4 appeared like it would be additionally perplexing. The tangential sway above resonance from the typical roller-coaster impedance was a head-scratcher. I did the same mod to this unit as I did to #1, and resulted in this:

This had a shape that was more like the others. That 'sway from 1k to 1.8k was still there, albeit at a different magnitude. Well, I didn't think that tearing back into the rear and stuffing would change anything for the better, as it should look like the other 3 if that were the inherent cause. OK, time to remove the faceplate and see what I can observe...

The surround is glued to the rear of the faceplate, so be careful if you remove the faceplate. Another note about the faceplate is that the polarity markers are really hard to find, and are on the structural cross-members. They are not on the terminals or the terminal supports, so I marked mine with a red Sharpie. They were also hard to see in the photo below, so they are enhanced for detail.

More in the next post...

Comments

I have no idea if they are supposed to align in a certain way or not, but I figured a 90* rotation was not out of the question due to how the interface was designed. I recall a time where Peerless/DST had issues with their DX25/XT25 tweeters' faces warping during the manufacturing process. In some cases, a simple one-position-shift of the mounting screws would solve the measured out of spec differences in those tweeters. That company decided to just start gluing the faces on to solve the issue. I have not heard of this problem with them since. I figured it couldn't be that simple, but why not? This is the result:

It's a little higher in magnitude than the others, but the T/S align really well with the other one I modded.

Just for comparison sake, here is the final results of the modded on the right adjacent to the factory ones on the left. I included a blurb of the previous abnormalities just for fun:

One more thing- #4 had about 3x as much cotton in it compared to #1. I wonder if Seas is not metering the stuffing amount as they hand-assemble these units. I am pretty disappointed that they were this vastly different initially- especially at that price point!

I am going to compare FR/HD and listening comparisons when the time comes...

InDIYana Event Website

InDIYana Event Website

InDIYana Event Website

InDIYana Event Website

InDIYana Event Website

InDIYana Event Website

InDIYana Event Website

Basically, a small format TMM consisting of Seas Al/Mg 27TAC/GB and a pair of Peerless 830991 glass-fiber midbasses in a ~30" tall tower. It's meant to have really low HD for minimal cost, and be a designed update/improvement to the PMC 'Twenty5' design- or at least initially that was the goal. The '25' appears to use the 830991 singly with the 27TDFC as the tweeter, formerly the 25TAF. We'll see where it comes out in results.

The Titan 27TAC/GB I'm using is a serious upgrade over the previous tweeters, and Joachim Gerhard measured it to have the lowest HD of any similar tweeter with level being at -65dB from 2kHz up. I found this out as an added bonus after I made my previously noted purchase.

The tentative F3 is ~45Hz, and a target sensitivity is ~86dB. The midbasses are of the series that RobSan tone-burst tested (830992) to have the lowest HD for the cost, and rivaling that of much more expensive drive units. Using 2 of the drivers will up my sensitivity, further reduce HD at output by halving Xmax requirements, and allow more room pressurization before rolloff. The '25' sounded really good and had extension, but seemed the level at that extension was a bit reduced in output. Using 2 will improve this.

Design being a short tower means optimizing for above the tweeter axis, 10" at the listening position. I designed for this to have an increasing lobe direction instead of being straight forward. I did this with the Nephila, and it did quite well. The summation in the EMP still aligns well even below axis, so I feel this is a good compromise. The comb-filtering of the woofers in addition to being mainly (above) off-axis contributes to a large hump at about 200Hz I had to filter out. This lends to a more complicated xover in the bass range, but leaves the unpeaky rolloff of the glass fiber cones rather straight forward. I'll be playing with the woofer rolloff, but it appears that 3rd order works better above the tweeter, and the 2nd order works better on the tweeter axis. 3rd on the tweeter electrically was my result, plus a couple other things. Since the tweeter has no FF, I comped the Fs with a full LCR. The 27TAC FR exhibits an ultrasonic breakup at 25-27kHz, which I also have a notch to compensate. I will have a switch on this and will be measuring both with and without the notch engaged to both see and hear the performance differences in measurements and listening.

Initial simulation:

The reason for the bypass caps is for use on this ultra-low HD tweeter, to see if they are audible. I'll have a switch on this too.

I have the initial xovers mocked up, as well as the 4-sided cabs constructed at this time.

Looks will approximate this:

More to come as it goes...

InDIYana Event Website

InDIYana Event Website

Sovcom: https://www.ebay.com/itm/4-pcs-0-1uF-0-1uF-1uF-500V-2-Silver-Mica-Capacitors-KSG-2-Russian-New-NOS/202556775527?hash=item2f29531c67:g:zHUAAOSwq~tZW2~U

You can't get Silver-Mica caps this large on this side of the pond, and the Russian stuff seems to have a good reputation. The price was right! They are more gold-tan than the yellow pictured.

So- I have 0.1uF PIO Russian K40Y9 and 0.1uF Ag-M Russian KSG caps. The PIO is supposed to warm up lower treble, and the Ag-M is supposed to be the best caps in the upper range- repp'ed as better than polystyrene.

We'll just have to wait and see....

InDIYana Event Website

InDIYana Event Website

It came out LR2 through the xover.

The higher Q tweeter rolloff coupled with the BDC signature needed a 3rd order of pretty low Q to achieve even a 2nd order rolloff.

The woofer has a dip in response at about 800-900, and this flattened out with the BDC signature, leaving a very minor magnitude dip. This coupled with the woofer's ability to work with a single coil makes this look really good to me! I used zaph's 10 year old FR measurement.

See for yourself:

If it wasn't for needing the Fs spike tamed, this would be a small parts count.

InDIYana Event Website

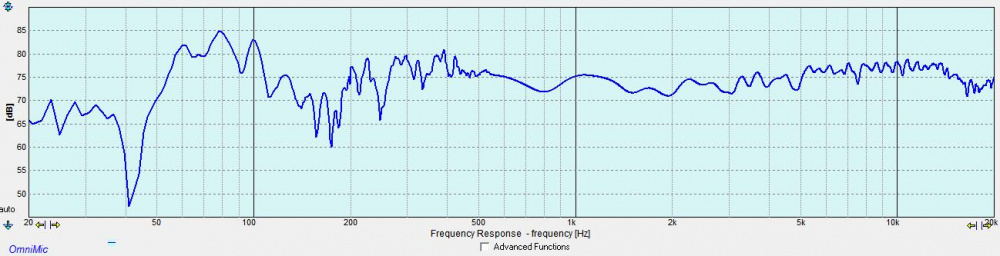

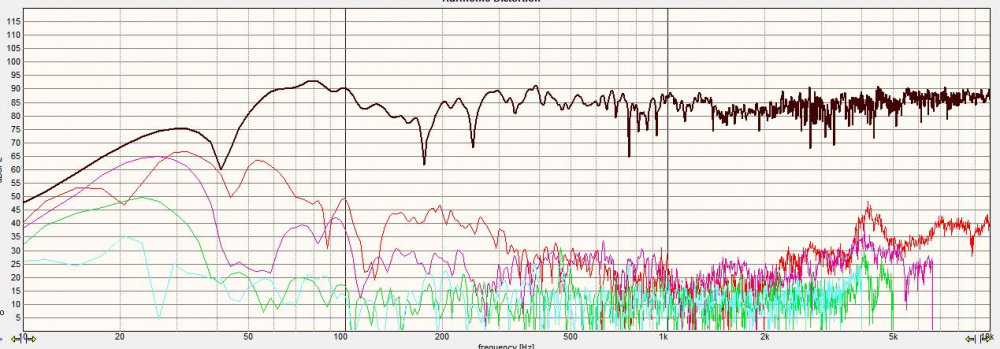

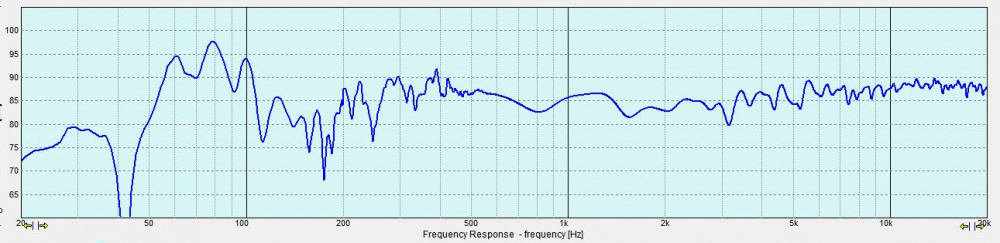

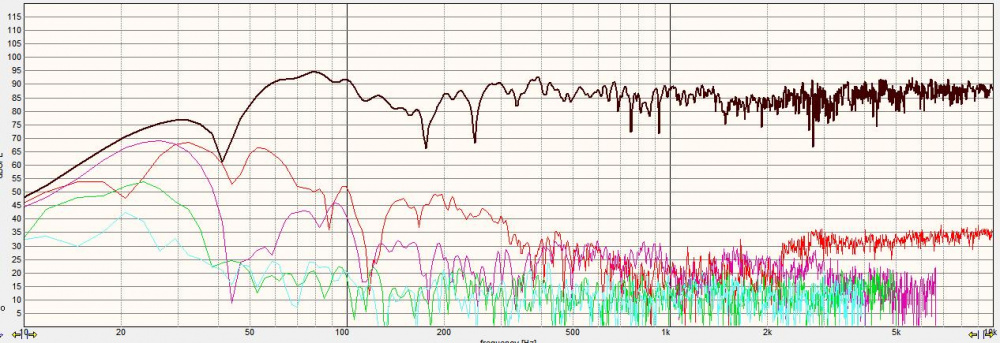

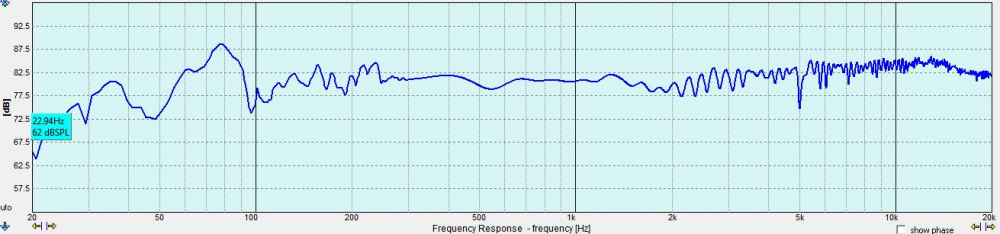

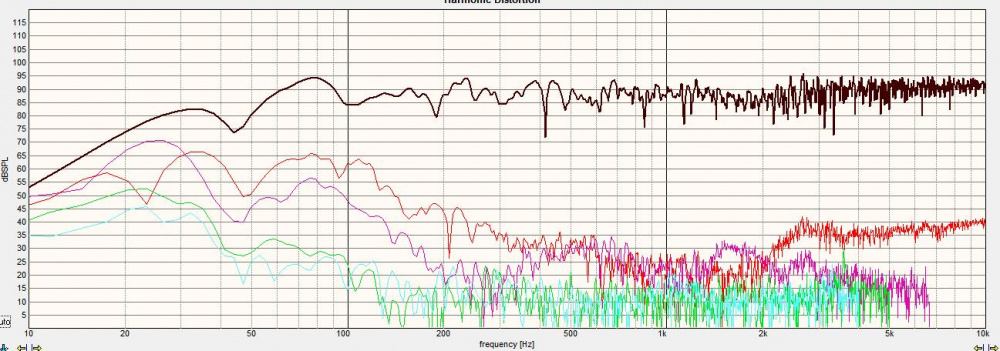

Well, some more information has arisen, as I now have measurements of the 27TAC/GB in situ, and of 4 samples seen earlier. Frankly, my modded units stomped the stock ones! These measurements are for the EMP as she sits currently, and I'm quite happy with the performance. This is with the Ultrasonic cut disengaged, and no bypass cap in the circuit.

These measurements are for the EMP as she sits currently, and I'm quite happy with the performance. This is with the Ultrasonic cut disengaged, and no bypass cap in the circuit.

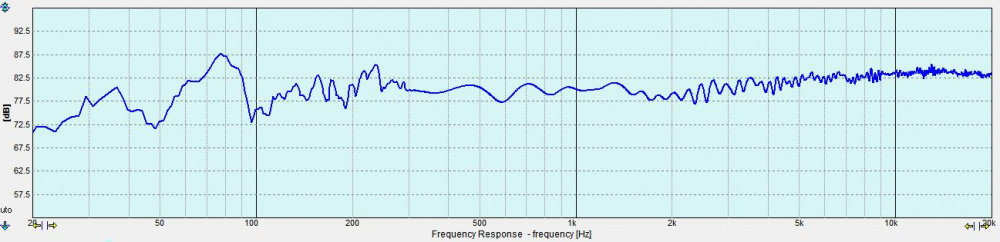

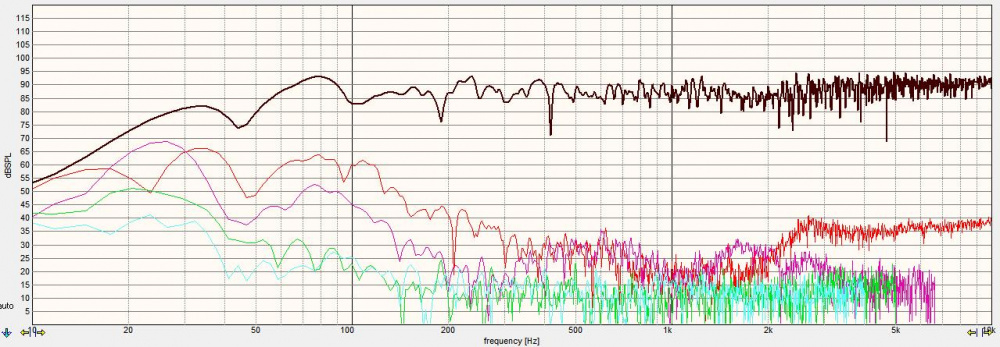

Stock unit:

Modded unit 1:

Basically the pairs that were matched reflected each other really well, so I won't post duplicates. These measurements are all with the right channel woofers.

I was really surprised that the sssibilance, minimal at that mind you, was actually a result of the HD signature and not having enough or ill-placed damping in the chamber.

InDIYana Event Website

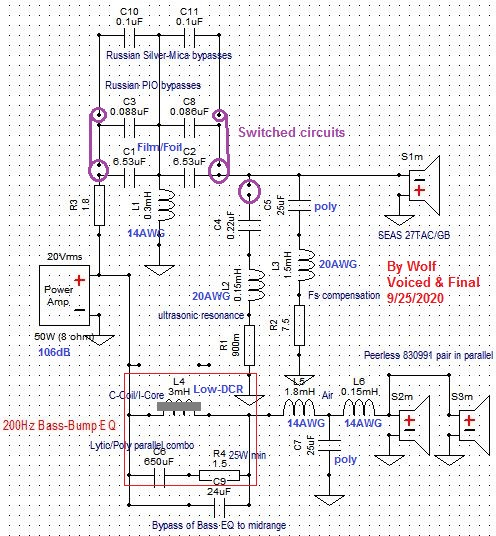

Network currently:

InDIYana Event Website

Did not know you used omni mic and now XSim... Nice x-o and labels. Part count reminds me of a horn 2-way

I use Xsim when I can't do it in PCD. I used it on the Cecropias too for the funky Lpad it required. I had the file already made in Xsim from the initial model for comparison, so I adapted it and threw it up on here. I've been using Omnimic since about 2016, but I've had it longer than that. I don't always pull it out and measure to verify. There was a full set of graphs made for the Zingers.

InDIYana Event Website

These apples look better...

Final schematic:

Changes made yesterday-

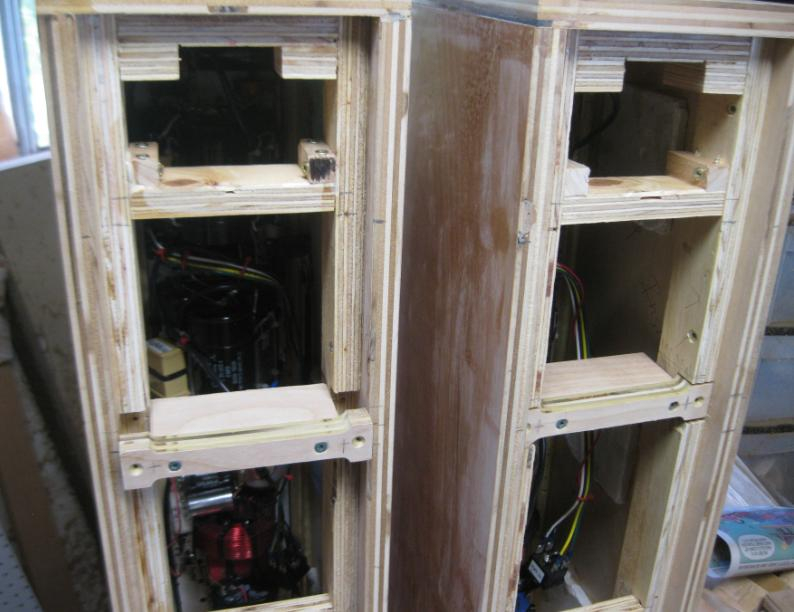

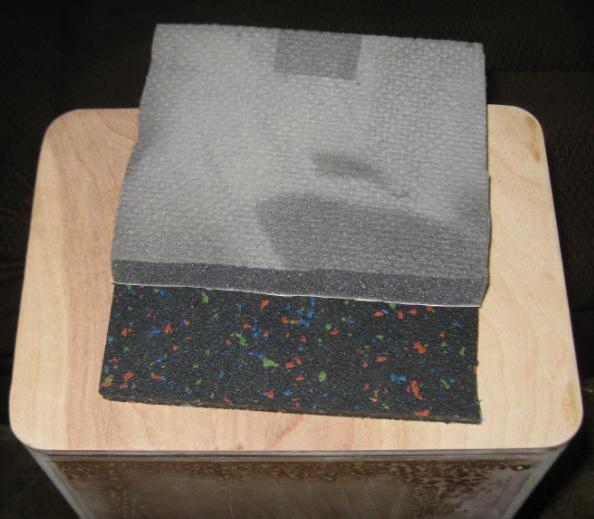

One of many things that are different about this build for me, is that there is no major bracing in the middle of the panels. All of the corners in the box accept for the side-to-top junctions have added corner bracing. This is due to the slot-port, the inner rails to mount the baffles, and the pieced rails to either side of the xover docks in the rear panel to make the width I needed. The sides/top have 4" square 1/4" thick marble(?) tiles with the mass-loaded Sonic Barrier chunked between them. The inside top wall of the slot has a thick rubber slab and 1" SB foam. Then I laid 2 layers of 100% wool batting over the back-mounted xovers. I will be adding more of this to hopefully tame the 78 Hz peak.

But I digress... AND- I used plywood.

The box is very strong and does not resonate. I managed to get rid of the plywood box hollowness that I despise using the techniques above. I don't normally use ply much, but it is easier stapled to than MDF. This meant that I could do the finish I want. More on that part later, but I'll have some of Lowell's spiked feet outriggers on the bottom.

Pics of assembly to come shortly...

Ben

InDIYana Event Website

Docking rear panel:

Tiles on side panels:

Sonic Barrier with mass layer applied:

Peerless trunky-circle jig:

Removable baffle mount and brace:

Inner end of bottom slot before elongation:

InDIYana Event Website

Tweeter recess:

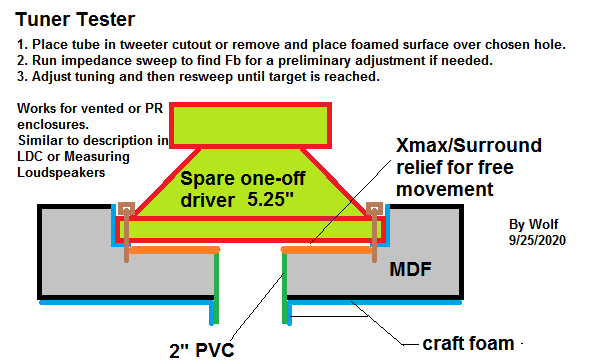

When I cut the tweeter hole, I wanted to measure Fb, so I made up a Tuner-Tester like they describe in the LDC, and Joe's 'Testing Loudspeakers', technical drawing of mine:

This allows me to test the Fb by placing the stuff in the cab that should be there, and not yet cutting the woofer holes. It will be a valuable tool to use on cabs in the future. No reason to show my poor-looking implementation.

Rubber tile and SB on the inner bottom:

Added 1.5" to port length:

Stuffing:

Terminals/switches:

Rear port exit:

InDIYana Event Website