Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Samcats

Sam and Cat got married.

Samantha is the daughter of a dear friend I met in 2nd grade. She's a struggling musician and I've promised her a set of speakers as a wedding present for her and her new wife. https://samraemusic.com/ I'd like her to have something decent and since they will have to be shipped they will be modest in size.

The drivers:

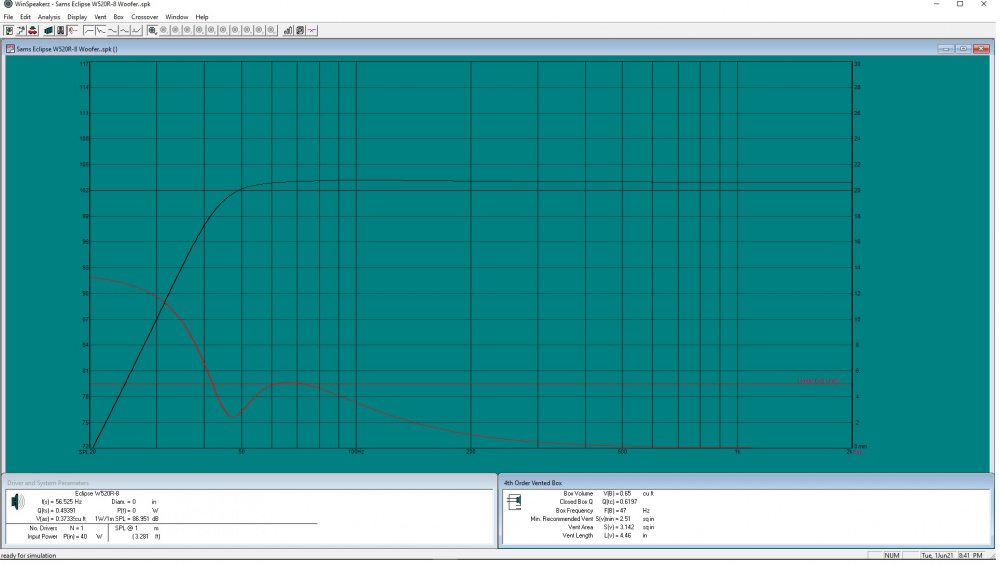

Eclipse W520R-8 https://meniscusaudio.com/product/eclipse-w520r-8/

Dayton AMT3-4 https://parts-express.com/Dayton-Audio-AMT3-4-Air-Motion-Transformer-Tweeter-275-093

Fountek RD1.0 https://meniscusaudio.com/product/fountek-rd1-0-ribbon-tweeter/

.65 cu.ft.

Solid walnut front baffle.

Ron

Comments

Congrats to the couple! We attended a wedding yesterday - they have been living together for ten years and finally tied the knot.

Brilliant idea for a wedding present!

Geoff

I think they have been together for 6 years. They were going to have the wedding last fall but postponed it until this fall. They ended up having it last fall with just close family anyway and let the rest of us know a couple of months ago.

I plan to veneer the box with walnut veneer and have a solid walnut baffle with a maple accent strip around the beveled baffle. I built a frame of maple from 1/4" strips and glued it to the box. the plan is to veneer right over the maple, glue on the walnut baffle and cut the 45 degree baffle back far enough to expose the maple.

Ron

I've done it before and made grown men tear up.

Pretty girl and cool project. Where is the picture of her husband?

Craig, you mean wife.

Cool project, the AMT and ribbon should make a good combo.

I love the combo of drivers you chose!

Started putting the walnut veneer on last night.

Ron

Sam has a lovely voice, thanks for the link.

Especially with COVID restrictions still in place here (Melbourne), most musicians in any genre struggle to make money. Some can make a living through teaching, but even that's not possible except on Zoom, which isn't exactly ideal.

Geoff

She just posted her entry to NPR's Tinydesk contest.

She has toured in recent years with Brandi Carlile playing cello.

Ron

I started cutting holes in the front baffles.

Ron

I finished up the driver cutouts today. Do not use my layout for the ribbon tweeter hole. I ended up with barely anything under the screw holes. I'll be patching in the corners with a little filler. The tweeter spec sheet has a layout for a hex cutout.

Ron

I made some 1/4' plywood panels to mount the crossover parts on. The woofer hole is only a little over 4 1/2"s wide and I don't want to have to fight to fasten the crossovers to the inside of the finished box. I made all the panels the same size and used one as a template to drill some small pilot holes in the corners. I recessed the bottom of one set of panels with a forstner bit for 8-32 t-nuts. It turned out that the nylon spacers I had could be pressed over the protruding ends of the t-nuts so they stay in place when the top panel is removed.

Ron

Clever!

InDIYana Event Website

I added some bracing to stiffen up the back panel and installed the crossover boards.

Ron

I made a template for the midrange rebate and lined the cabinet with foam and cotton insulation.

It's time to mow the lawn now that it's not 102.

Ron

Have you gotten any rain there? It is super dry here (only 0.2" the last 3 weeks).

Looking great! I love seeing all your planing come together.

We are in a severe drought. We had a 1/4" a week ago which is the only rain in June.

Ron

What plan?

Ron

I glued on the front baffles.

Ron

My problem, illustrated somewhat with this picture of the baffle glue up, is that when I use my bottom bearing flush trim bit to trim off the excess of the baffle overhang, it often leaves a groove in the veneer that I have to sand aggressively to eliminate. My last project, I even tried using some painters tape on the sides before I routed, and I still had deep grooves.

How do you deal with this?

You might need to change/upgrade the bearing, Don. Doesn't take much for a bearing to drag a bit.

Sometimes this has to due with depth placement. I have one bit that will be a touch wider than the bearing, and it will do this. I have to set the bit at the edge of the panel being cut to avoid it.

InDIYana Event Website

I try to use the largest bit I can. I know 1/2 is most peoples go to but I use a 1 inch when possible. The larger bearing is great and the larger diameter bit is a natural smoothing. 1/2 inch divit is a lot harder to sand out and hide than a 1 inch divit.

The baffle in the picture hasn't been trimmed yet. Tape helps but I still have seen bearing marks in some of my projects. I use 2 ply NBL veneer and and I just measured the veneer I used and it's .036 thick and about half of that is walnut so I can sand it without too much fear within reason. I do avoid sanding until the very end just because I don't want to sand any off before I leave a mark I really need to sand. You can repair small dings and divots with a little water and an iron which will swell the wood.

They make laminate trim bits with square bearings. I wonder if you could swap bearings with a flush trim bit?

https://woodworkerexpress.com/amana-tool-sqb100-euro-square-bearing-guide-od-1-2-id-3-16--223-thick.html

Ron

Ron, are you suggesting to use a sqaure bearing or a round flush trim bit?

They make small laminate trim bits with square bearings and sell the bearings separately. I was wondering if you could substitute one of those bearings on a flush trim bit.

Ron