Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

DrewsBrews InDIYana Theme Build

The challenge rules:

2-way passive designs only, stand mounts preferred but not required.

cabinet volume to be 1.5ft^3 or less.

woofer must be an 8-12". Yes, I said 12".

no tweeter faceplate must exceed 4.125" diameter or edge to edge.

no large waveguides allowed, see faceplate rule.

no dollar limits, spend or not!

no in-stock, buyout, or NLA driver limits. If you have it on the shelf, the above apply, and wish to use it- PLEASE DO! Use up the stuff you've had sitting.

No cabinet over 40 lbs will be hefted for demo by the InDIYana planning crew. If you build heavy, you can set them up!

Tweeter: Peerless DX25BG60-04 (BEAST MODE!!)

Initially I was thinking of going wacky with a CD on a tiny horn. But, I still have a lot to learn in the hobby.. And, though I'm fine subjecting myself to my heinous creations; I thought it would be a better idea to take a safer route and go more traditional. In research early-on it seemed like Beast mode was the current winner the in bang-for-the buck department for low XO... Then it went on sale over at Madisound so that forced my hand. My inner cheap@$$ could not resist.

Woofer: SB Acoustics SB20FRPC30-8 (New "fullrange" 8")

I have some Tangband w8-2145s that seemed like a good candidate for decent SQ. Though I have yet to hear them.. and I wouldn't pay the price they are at now.. So if they were damaged in handling and transporting I would be really bummed. I saw these SBs come up for a very reasonable price, good efficiency (92db/w) and seem to have similar enclosure needs so I jumped on them.

Enclosure: 1.15cf mdf. 13.15"x18"x11.75"

A design I came up with a couple years ago to get the most out of a 2'x4' piece per enclosure... and it is about the biggest I can reasonably fit in my small living room. I built these earlier in 2022 for the w8-2145s. Glued up with a couple side-to-side braces already in and edges flush-routered back down. Fortunately procrastination kicked in, then I heard of the 2023 challenge.

A 2" port 5" long (a pair of 2" precision port flares butted up) will yield an F3 ~54hz with a 2db upper bass bump.

In this enclosure/tuning they will tickle xmax at 14.5watts. Unloading to breach xmax at 27hz. With 2" port the air velocity climbs up to 27 m/s. But the precision port flares should help, and maybe that can help provide some over excursion protection via power compression?

I've read an LCR notch may be suggested for low xo points to tackle the resonance peak. But I'm not experienced enough to know just how much attenuation is required. For 1.5khz would a 4th order electrical be required with the DX25BG60? I've seen folks use 2nd order for 2khz XO (no notch) on this tweeter and it sounded pretty dang good to me.

Comments

I don't know the answer, but I **think ** the right question is whether 4th order **acoustic ** is required to xo at 1.5Khz. The electrical will just depend on the natural roll off to get you to the acoustic target you are after. I'm sure someone will correct me if I'm wrong.

I crossed this tweeter at 1.8Khz. It was my first speaker design and when I pull up my old PCD files it looks like I used 2nd order acoustical (and electrical) xo's. However, the images aren't coming up and I don't use PCD anymore, so although I do think that is correct, I'm not 100% sure.

Yeah true... I finally just figured out what the heck I'm looking at when it comes to distortion graphs, so knowing how much attenuation is required to limit tweeter over-excursion is still kinda voodoo to me.

Based on wavelengths, I suppose keeping to an 8" woofer might provide a little room to bump up the xo point a bit before the off axis response gets murdered (vertical being worst I imagine). Guess I'll just have to see.

Oops repost

That's an interesting 8" driver. I look forward to hearing it. That's also an interesting bass alignment. After you get it all put together and you are voicing the crossover, for the fun of it I'd try stuffing some socks in the ports just to hear how much different it might sound as a sealed box alignment. Not saying it will be better that way but you never know.

The Beast Mode has a pretty high sensitivity with a low Q impedance peak. Crossing it LR4 at 1.5kHz you probably won't need a full on impedance notch (LRC) in parallel with it. Since you're going to need to pad it down to match the woofer, try a 10 ohm resistor in parallel with it, then whatever series resistor necessary to level match.

Yeah the box is pretty undersized for the specs I measured. When I model the same enclosure, but sealed, F3 only raises by 8-9hz with ~.8db bump higher up. However it shows power handling capability drops by near 1/3rd. By 11 Watts it is already breaking past xmax.

At least if I port it I'll have the option to try both ways. I may end up stuffing the port when using them at home. As space constraints necessitate putting them only a few inches from the wall. The close listening distance would make the power handling more moot as well I suppose.

The factory specs are happier with this enclosure. Though it really doesn't change the response much (upper bass bump drops in half... 1db). I only just recently got my DATS so I could be not doing the measuring correctly. Using blu-tac type stuff for added mass. Weighed with a little digital scale that I verify with a known mass. Is there a good range of mass to use? two pieces of blu-tac come to about 110 grams. too much?

I was hoping someone would use that woofer.

InDIYana Event Website

You could try the DATS Mmd method to determine Vas. Vance Dickason uses this method instead of the test box, SPL or added mass methods. Most vendors specify Mms (includes air load effect) instead of Mmd, but you can calculate Mmd from Mms. Using the air load formula:

Mmd = Mms - (8/3) * rho * Rd^3

= Mms - 0.0032667 * Rd^3

where

rho = density of air = 0.001225 g/cm3

Rd = effective piston radius in cm

So for the SB20FRPC30-8:

Mms = 16.3 gm, Sd = 216 cm^2

Rd = square root (Sd/Pi) = 8.29186 cm

Mmd = Mms - 0.0032667 * (8.29186)^3

= 16.3 - 1.86237

= 14.4376 gm

You can use this method to cross check your results when using an alternate method.

Marked up the measurements and made mdf dust this week.

Woofer rebate is a snug fit, but for the tweeter rebate I set my rudimentary circle cutting jig about 1/32" too far our. Ended up about 1/16" too large. oah well

The port has been on backorder for a while at PE so I had em shipped in from Madisound.. Just arrived today. Unfortunately I didnt document exact location/dimensions of the internal braces, but I did have some screw heads on one side to give rough location. I cut the port holes too close so Ill need to shave down one side of the inner flare to clear.

The side-side braces were the only ones pre-installed. Ill probably add 1-2 front-back braces now that the driver holes are defined. Not sure about the top and bottom. Doubt I could get a full length piece in through the driver holes. Maybe a couple angled braces to tie into the sides.

I am really interested in how these ^ SB Fullrangers sound and are to work with in developing XO's for them.

The fullrange nature tends to necessitate a lower inductance. So I anticipate the lowpass to be pretty easy going.. Less impedance rise to fight with.

I did run some music through the 8" for a few minutes. I didn't find anything obviously bad about it, and can definitely tweak the response by adjusting how far off-axis you are listening. I may play around with it after InDIYana

I ran some quick n dirty sweeps to find the time alignment. The woofer comes in little over 2.6" back from the tweeter.. Seems like a lot.

[Edit]

Had an oopsie in my OP. The 2" Precision ports have a usable length of 2" (not 2.5"), paired up for 4" total. F3 drops 1hz, xmax breaches a couple db higher. So not a big change. Still playing in the ballpark of the suggested combinations for the 8"

I had the same issue with a 3" aeroport. I just chopped them down and epoxied them back together.

Slow going up to now. Working on re-drywalling a room after nearly completely rebuilding it.. Structure, roof, windows and siding. (was a poorly converted old porch)

For the speaker boxes I put in the front-back braces then filled and sanded the outside. Hosed em down with a few coats of water based poly to seal em for now. Was pretty sloppy so plenty of runs. I'll just block sand em down for a final coat. Deciding to leave em as-is for now or hit em with some paint. Probably just use some spare leftover wall paint: Have a nice flat red brick color, or a satin blue called "skinny jeans".

I just wanted to get them sealed at least since I'm planning to apply some 1/2" felt on the baffle. Didn't want to deal with soaked-in spray glue if I wait to paint them later.

Really need to get my butt in gear or I'll probably get burned by back-orders on XO parts.

Good proportions on these.

Sorry I missed seeing this part of your thread. Are you sure it's 110 grams? That is probably at least twice too much. You only want to add enough mass to drop Fs 25%. DATs will tell you if it's not enough.

And even when you have "enough", VAS is pretty sensitive so adding a little more weight doesn't trigger any alarms but may give you a pretty different measure of VAS. I bought a few bags (maybe 4 to 8) of Fender washers in different sizes (Lowes or Home Depot or ACE) and get to the "enough" range for DATS and then measure a light, medium and heavy version (which is usually something like 4, 5 and 6 washers depending on the driver). Then I just use one of the measurements that seems reasonable to me.

Awesome thanks! I figured I wasn't doing something right.

What's the consensus in using dimes, pennies, nickels and quarters?

Steve, I have done that many times but find that measuring out heavier objects works better. At one point was getting odd results because the change was stacked unevenly.

Sounds like money.

https://www.jfcomponents.com/

I originally saw nickels and quarters used on the PETT boards - I figured my kids would take those but would leave the washers alone Some people will also put a little folded piece of masking tape on the backs to keep them from jiggling from the test-tone, but I don't bother with that.

Some people will also put a little folded piece of masking tape on the backs to keep them from jiggling from the test-tone, but I don't bother with that.

I use modeling clay.

What does she look like?

OK, I understand the issue ^ Ken mentions but what if you just place 3 nickels equidistantly around the cone or quarters if a larger diameter/Bl driver is under test?

I'm just trying to understand what you use as weights and when/where . . .

That is how I do it, equidistant around the dustcap perimeter. Usually it takes 3-5 nickels at 5g each for most midbasses. The most I've had to use was 30 nickels on an 18", so I keep that many set aside just for this. For phase plug drivers, I have a small plastic cup that has been weighed and labeled, not unlike a medicine bottle. I invert it over the plug and stack the nickels or other mass on top of it.

InDIYana Event Website

I use nickels. Yeah, usually 4 - 5 for a 6-7" midbass. I'll wrap them together with thin slices of blue painters tape. I'll use another piece of blue painters tape rolled over inside-out to stick it to the center of the dustcap. I've used Mortite (rope caulk) formed into a donut and layed around the extended pole piece when necessary. That works great for metal cone speakers and paper cones that are coated, but it left a residue that soaked into one of my uncoated paper midbasses once

Interesting. Here I figured it would be necessary to have it somewhat adhered to the cone so it was a mass that resisted both directions of cone movement rather than just weight bearing downwards. Past a certain frequency the cone would be accelerating downward faster than gravity and the mass would just be bouncing on the cone. But it sounds like the test isn't affected by that.

It has been my experience that the added mass must be securely adhered to the cone to get consistent measurements. In addition, measurements are also affected by how you hold the driver during measurements. I built a clamping vise and ran some tests a while back: https://diy.midwestaudio.club/discussion/comment/32082#Comment_32082

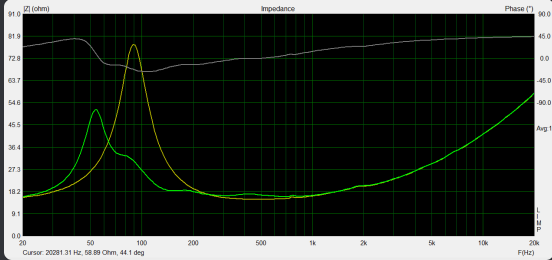

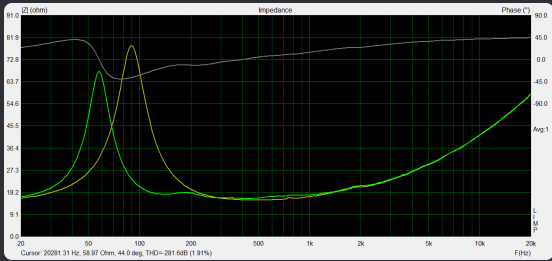

If it is not secure, you will see abnormal lines:

vs well secured:

Same driver, same added mass, second time I pushed the playdoh harder to ensure good contact.

I have not had that kind of difference between such measurements, but I'm using a WT2.

InDIYana Event Website

cool. Maybe I misunderstood what they were saying.