Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

MAC-06 and GRS open back tweeter bookshelf

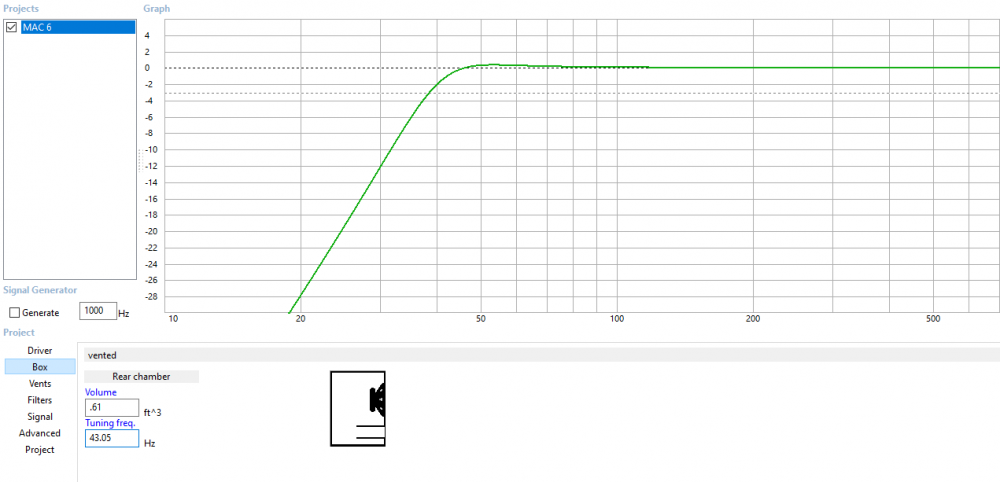

I have a few projects in line for Christmas break, since my company shuts down for the week between Christmas and New Years. I have really wanted to try out the GRS PT2522C-4 in an open baffle arrangement since it came out. I really wanted to try it in an omni/open baffle configuration. I tried that first. I measured it, and it was a mess. It really wasn't worth the crossover components to make it work. My second choice was something similar to the GR Research NX Studios. I was asked last year to do the veneer and paint work on a pair. The voicing was not to my taste, and neither was the sealed 6.5" driver. They just seemed thin. I thought I would try something similar, but with the GRS tweeter and a MAC 6" woofer vented.

This is my try at an omni speaker. It was thrown in the trash after measurements.

This is where I am at with the bookshelves.

Comments

The fronts are recycled 1.5" thick butcher block counter tops. The back will either be painted black or veneered. Not sure yet. The boxes are ~.6 cubic foot enclosures tuned to 43hz.

I started on the crossover. The tweeter was difficult to work with. It had a weird roll off and was tough to get the phase in line with the woofer. I ended up with a first order and a notch on the woofer and a second order and a notch on the tweeter. I just order a few components I was short on from Jule Fidelity and will see what this sounds like.

I played around with the woofer full range to get a feel for what it sounded like. It seems promising so far.

Those look great. Sims look very promising.

Dan NeuBecker, who did several omnis, typically used a convex "diffuser" above the woofer and mid. But this looks like a fun project in any case.

Awesome!

Threw some stain and poly on the fronts. I need to figure out what to do with the rest. I have some urethane paint left over from a motorcycle I painted this fall. I may use some of that.

Having built something very similar (2 projects actually) I would strongly suggest a piece of 1" damping on the top of your woofer enclosure.

Wall thickness or internal fluff?

He is saying damping laid external atop the enclosure should be used for reflection reduction off the rear wave of the planar.

InDIYana Event Website

I was thinking that would be worth experimenting with. I was going to use something with an adhesive back after I paint them.

Yes this.

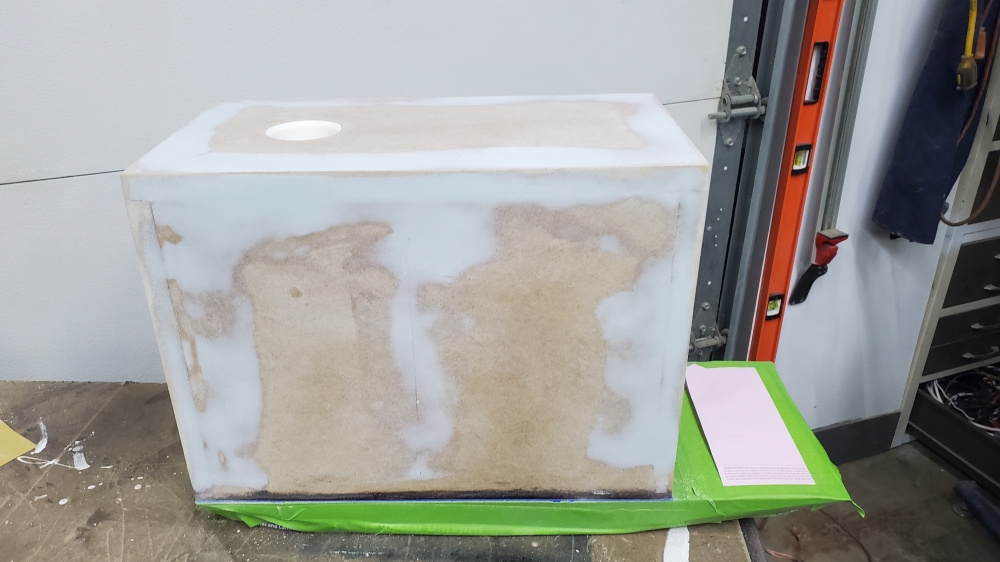

I got bondo on the boxes, and am priming today. I am using some high build sandable 2k primer. I wish I could afford this stuff on all builds.

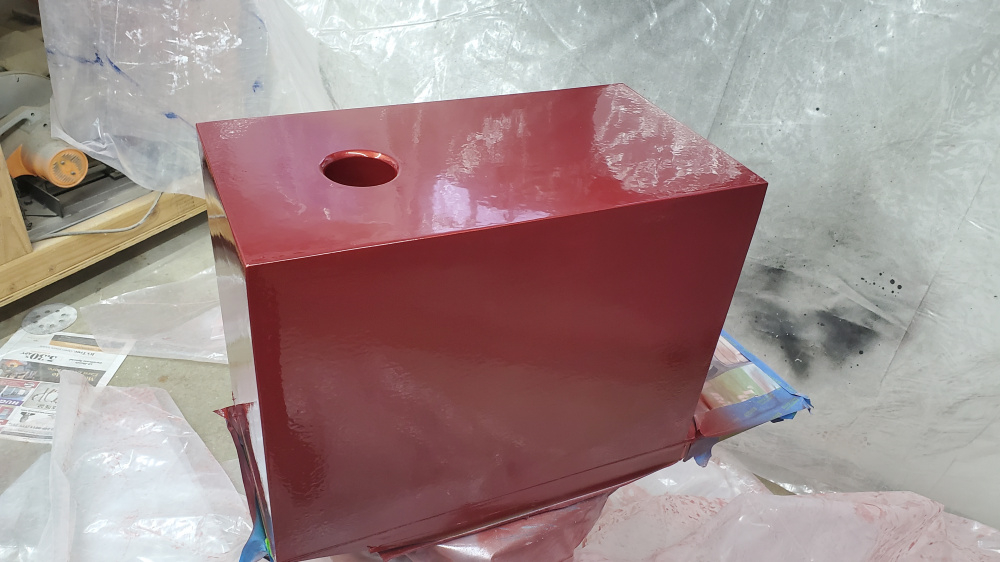

Just got the basecoat on. Will do the clear next.

Clear coat is done. Just need to start voicing the crossover once everything is dry.

Nice!

https://www.jfcomponents.com/

Better you than me. gawd I hate painting!

So do I. My shop is a huge disaster right now, and I have to wear a paint mask to go in it due to the smell. I usually only paint with automotive paint in a diy paint booth I made using an easy up outside in the summer.

I'm not a huge fan of building the cabinets, but doing the bodywork and squirting I don't mind at all.

Got the speakers assembled. Now to cobble together a crossover to test.

Cool speakers and garage🤘🏼

I like the look of your baffle...

I just finished up the crossover. II have to say, the MAC driver is really good for the price. The bass is better than I expected. It was also really easy to work with. The GRS on the other hand was a huge pain to work with. It also took a fair bit of tweaking to get rid of sibilance. It all sounds pretty good now. Below is my measured response where I landed and the final crossover.

Using the Neo3, I had the same issues. It was hard to get it between sibilant and dull.

InDIYana Event Website

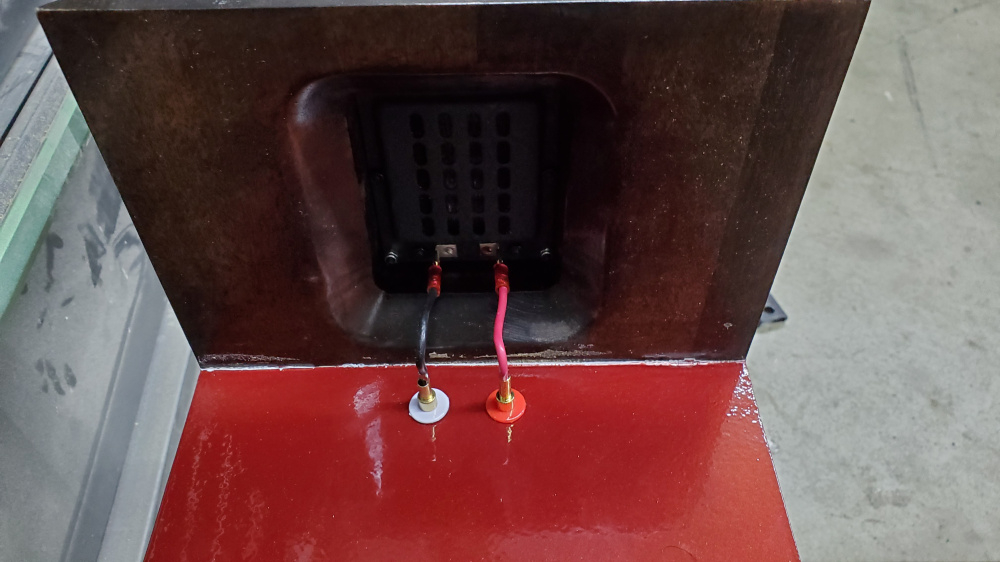

Here is a pic of how I wired the GRS into the box. I used some tube connectors that were given to me. I really didn't have any other use for them, but look good in this application.

Have you tried listening with and without a little damping pad on top of the enclosure? My last project with an OB planar like you have had weird imaging without it. Almost like the singer was sometimes 3 feet higher than the actual speaker. The damping pad cured that.

I did. I used some mattress topper on it. I plan to order some sonic barrier from PE to put on top long term, unless anyone has any ideas on something that would look better.

Could try 1/2" firm felt. Can typically find in white, cream, and various grays. I think I got mine off Grainger.

Not a bad use of tube connectors IMO. Though I'd probably just drill a hole to pass the wires and seal with silicone.. covering any ugliness with the felt on top. Ive done one build with a tweeter up on a "flying" section of baffle. Not dipole, but I did need to cut a relief for the back cup to stick out. I ended up hiding the wires by drilling down behind where the tweeter flange would cover and through the baffle at an angle into the enclosure.

I was going to suggest felt also but the price has went through the roof. This is the felt I use in my more hi-end builds.

https://www.thefeltcompany.com/eco-felt-1-4-thick-x-60-wide-3-yard-minimum/

https://www.jfcomponents.com/

Wow, that is pricey. Look good though.

I bought mine before the sheep went on strike.

https://www.jfcomponents.com/

One piece cut in half should be more than you need:

https://www.mcmaster.com/product/87415K17