Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Honing my own skills - An 8" 2-way using a waveguide and leftover drivers

I say honing... but what I really mean is testing myself since I've never tried an 8" 2-way or anything with a waveguide before.

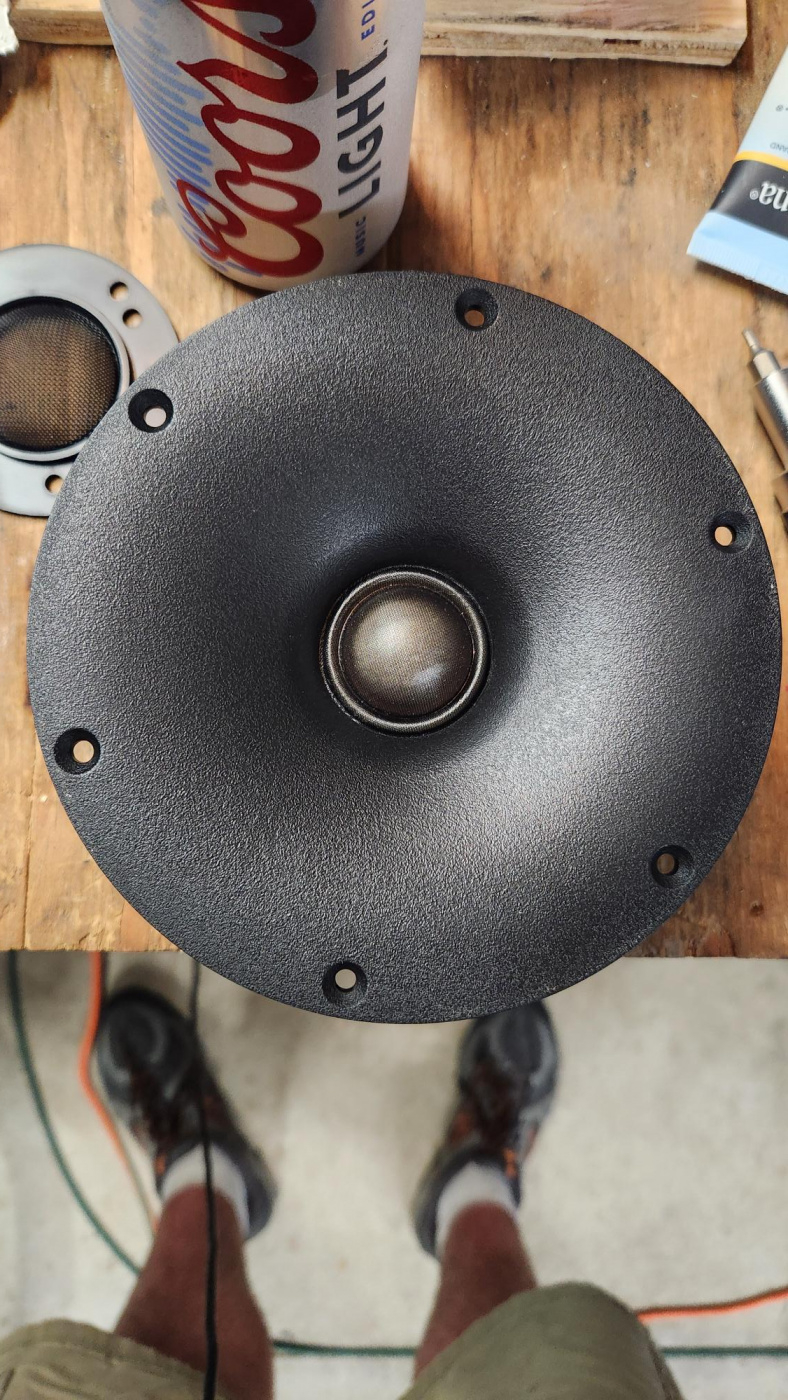

I've got a pair of NOS ScanSpeak M22WSR46-08A woofers (that were supposed to be in my towers until one of them had a defect) that I've got laying around from a buyout. I've also got a pair of Usher-built RS28F tweeters and Visaton Waveguides I wanted to try something with. So, this is that.

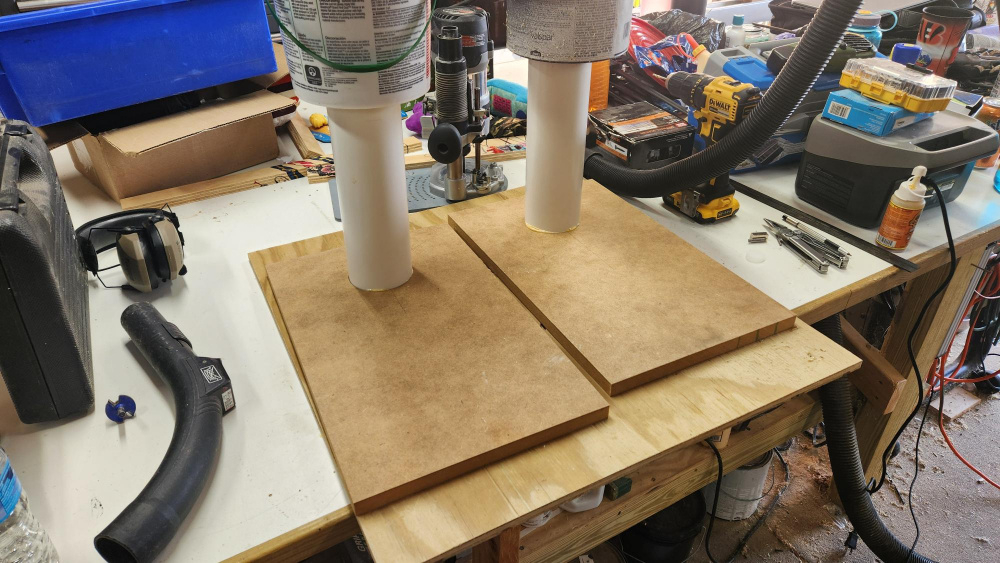

I'm very early on at this point, cabs are in progress. Large bookshelves, about 1.2 cubes total tuned to 35 Hz with a 3" rear port. 1.25" thick MDF baffle, 3/4" everywhere else and a single window brace separating the two. My goal with these is to see if I can design something with constant directivity. The waveguides are small compared to the woofer frames, but the diameter of the cones are similar to the waveguides. We'll see how this turns out.

I've got to remove the tweeter faceplate and DIY a method to attach it to the waveguide. I know how I'll do it, I just haven't done it yet. Its just sitting in place in those photos.

I'll keep y'all updated.

Comments

This looks like a really cool build. I love the looks of the wofer.

Should be a real nice build. I'm very happy with my first waveguide speaker.

If constant directivity is the goal, you'll want a larger waveguide. WG148 provides a good directivity match with 152mm midrange and 2 to 2.5kHz crossover, but will fall a bit short for an 8" woofer, though it will still be an improvement over a flat face plate.

Of course, WG size and profile is not the only factor, there's also cabinet shape, edge profile, driver separation, crossover frequency and crossover slope. A fine balance...Enjoy the journey.

To dcibel's point above...I see you already have cut driver/WG recesses, but Augerpro has a 3D printable 8" waveguide for the RST28F. I don't know how close the RST tweeters size are to the originals but I bet you do.

https://www.somasonus.net/dayton-rst28

Bring it to Iowa, we can compare notes on 8" 2-ways.

I appreciate the feedback so far, if its not perfect its not perfect. With the waveguide and tweeter choice, I'm hoping for a crossover below 2kHz. We will see what happens when I get these measured. Center to center spacing is just shy of 8", which is pretty steep, but I know that tweeter can cross as low as 1,500 without a waveguide. I am sure I will try something else down the road using what I've learned from this. This is just an experiment and will probably end up being gifted to my buddy.

The cutouts are at a standstill right now until I get a longer router bit delivered, hopefully Thursday. The one I have doesn't cut deep enough to go through 1.25" baffles. I'm wanting to finish these in walnut veneer with small round-overs on the edges. The MDF will probably show through, but I think it will add an interesting contrast and not be very obvious. We shall see. Never used walnut veneer either, so I'm trying several new things out.

This is what happens when you've built/designed for 20 years and work for PE. You start to do things for almost no reason whatsoever anymore lol.

dcible,

Are you saying this WG wont load below ~2k? I just re-read your comment and had me curious.

You could flip the baffle and router the other side as long as they are not yet attached.

Actually kinda interesting you are doing a large woofer 2way with the RST28F, as I will be as well soon. I cut baffles to fit the VersaMonkeyBox and drew circles this afternoon. However, I will not be using a waveguide, and I'm using the SD270A-88 for the woofer. Targeting a size like the smaller DeVore Orangutans (0/93?), and trying to make it inexpensive and easy to build. Sortof an upscaled Zinger, called Pangolins. I'll start a new thread when I have more ready.

Keep it up, Matt, and it's good to have you here!

InDIYana Event Website

Didn't care for that wg.

@petechman - in case it is useful...

Keith Etheredge used the RST28F in a Visaton waveguide in his Defiants build and shows his adapter in his detailed writeup.

Nick (ugly woofer) used the same combo in his Aliquis.

Baffles are glued already. I'm committed and stubborn, so well see how it pans out. It won't be my last WG design.

Glad to be here!

Care to elaborate?

The reason I use a larger diameter bit for cutting holes on the circle jig is I can then use a top bearing small diameter router to finish the hole.

InDIYana Event Website

You'll find out for yourself soon enough.

I am very interested in this waveguide project.

This project is similar to what I had bouncing around in my brain for my next build. I was going to use a Peerless 830869 and the "Beastmode" in the same WG. Now I'm wondering if I can push that woofer out to 2K without causing a complete mess off axis.

Brief update. My longer router bit came in today so I was able to get the holes cut and test fit drivers. I'm quite pleased with the results.

I did some brief testing with my OmniMic and the WG tweeter (not mounted) in the shop last night and I didn't expect much from that but I was curious regardless. I moved the mic around a little. I didn't bother saving anything but the results were promising. I'll know more when I get some hardware to get my tweeters mounted to the WG's and test everything in our chamber.

I do like the look though.

Love the Mouseketeers bracing and the waveguide looks right too.

Do you have enough clearance between the back of the tweeter and the port opening, Matt? (Looks close).

There is plenty of space, it looks minimal in the photo but its enough. The tweeter is only going to be about 1-1.25" behind the baffle when its all said and done. I'm hoping to get those mounted to the WG's today, I picked up the hardware earlier. If that happens I will likely take them to the office tomorrow for measurements.

How is it that Home Depot has an entire aisle of machine hardware and never has what you are looking for? I didn't think #10-32 round head 2.25" long machine screws would be so difficult to obtain.

I feel your pain. When working on a project, I like to keep moving and get things done. I usually end up driving to at least 3 or 4 hardware stores in an attempt to find the part I need.

I hate spending more than I should but my locally owned Ace Hardware store has a killer selection of fasteners. Even metric stuff. Stainless, brass, nylon, and regular old zinc plated steel. I figure the owner and most of the employees there live in my area so I don't fret over a few dollars more, especially when I can drive there in two minutes and not have to wait and pay shipping.

+1 on Ace Hardware.

I just now anticipate multiple trips to our local ACE for each project. By now the car knows its way….

Not sure if you have Menards where you live but they have a sort of decent selection of fasteners. Better than HD or Lowes.

In a real pinch I have a local privately own hardware store that has been in business since WWII. They have EVERYTHING and their guys know their stuff. Got a leaky facet from the 1920's or later... they probably have the seats and packing for it. The only reason I don't go there all the time is they are quite a bit further away, in a shady part of town, and have limited hours of business. Sorry to side track your thread.

Yep, Ace is usually my go to for hardware. I tend to think Amazon is cheaper with more selection if you can find what you want, but then I have to wait for arrival. We have a DoItBest hardware about 6-8miles down the road, and my last ditch effort is to try there, but limited hours. The old city hardware closed some years ago now, but they had everything.

InDIYana Event Website

So I must be the only one who orders at least 100 of whatever fastener I need even if I only need a couple.

Nope. I do the same. Even buying from Ace, I overbuy.

I usually do too, just there are so many to choose from, and so many different types that suit individual cases.

And of course running out periodically....

InDIYana Event Website

+infinity for Ace. We used to have a home store called H&S in Louisville that was a mecca for hardware, unfortunately it's no more.

Also just found out Mendelsons in Dayton is gone as well. If any of you guys got the chance to hit there, you'll know that was a hardware landmine. Always wished that place was closer. There used to be a PE store in there, was my first brick and mortar experience with Parts Express.

Yep, I'd rather have a few extra than have to make an emergency trip to the store.

I got to go in there once. Shawn led the way there. Jaw was on the floor the whole time. Coulda bought almost anything this group is into there. Heatsinks, cases, transformers, large caps, magnets, etc...

InDIYana Event Website