Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Killer Queen Build

Hey guys. Been a long time since I built anything for myself. Dan and I decided to start switching off each month and building something cool while filming it for our YouTube channel. I went with a crazy over the top build that I should have known I wouldn't be able to finish in 30 days but went for it anyway. I'm calling it the Killer Queen as a nod to the British rock band but also insinuating that they are KEF killers.

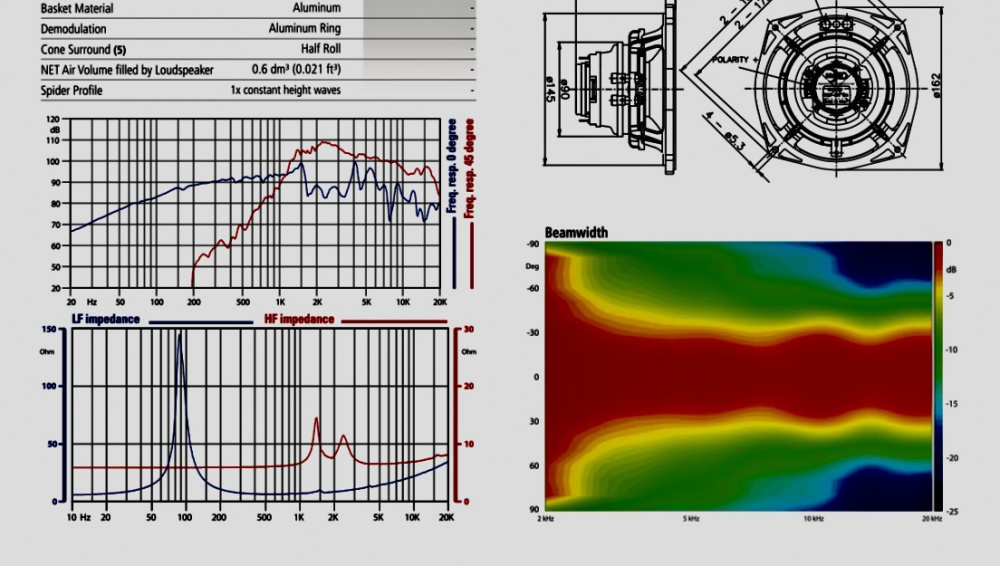

This coax is going to be a beast to work with. I've taken measurements and the mid has a really weird breakup that causes the worst drop off in frequency response I've ever seen. I guess the one benefit is that it doesn't really come back off axis so I don't get weird peaking but the compression driver barely extends low enough to cross passively. This thing really wants an active crossover and almost makes me want to go that route... almost.

I'll post some of the measurements later today for you guys. I'll be doing another video detailing the whole design process, measurements, and crossover in a few weeks.

Comments

Gorgeous work, Sir - really enjoyed the build video.

Awesome build video. Lots of great tips. Like how you stopped routing the woofer cutout depth just shy of 3/4" and then punched out the slug with your fist. Really cool. There are so many great DIY tips in this vid! I will have to watch it several times to absorb them all! You mentioned a future vid on measurement techniques. Will be looking forward to watching that when it comes out. Thanks for sharing!

Thanks for the video! Great tips on building the cabs and dealing with mistakes along the way.

Excellent build. For what it's worth the 8" and 10" Faital coax's aren't easy to work with either.

Such a shame to see that veneer get painted over, but I get it.

Naah. No need to recess the binding post plates. I never will on my builds.

Lovely!

There’s something strangely satisfying watching a build like this.

Perhaps it’s the gorgeous fine detailing like the inlays or accents.

Or perhaps it’s the living vicariously through others-

something that takes us months (if complete) seem to appear like it was done in 22 minutes!!!

btw, don’t feel so bad about the coaxial- that’s typical of pro-sound coaxials. High sensitivity but slightly raggedy response, and the off axis doesn’t match the off axis; so the best you can do it try to optimise your XO for, say 15 degrees off axis, or the power response.

To get a KEF-like response you really need to build your own coaxial with highly optimised geometry, including tweeter waveguide and baffle design…

I have punched out hole cores before, and had a large area where the MDF cracked away and left the board thinner around the mounting than the rest of the baffle. I would say that sometimes this works, and sometimes it doesn't go as planned.

Did I see a Wavecor/CSS woofer with a copper phase plug like the old SDX7? Hmmmmm....

I like the aesthetics, and hope we get to hear these in a few weeks...

So, is this the company wood-shop, or one of you/Dan's places?

InDIYana Event Website

I watched the video last night - great job! I love the aesthetic design choices you made.

Past experience has taught me to route through holes down to just a paper thin layer to keep things centered and then pop/cut them out.

This is a really fantastic video, I'm looking forward to this series!

Thanks!

Good to know for any future builds

Yeah, it looked really nice next to the black and I might use it in that configuration in the future.

I’ve got something that I plan to test this coming week which has an incredibly smooth directivity index. The power response still shows some of the wackiness of the on axis. I’m using two notch filters on the tweeter and one on the mid to get it into a reasonable solution

That driver was a prototype SDX7 we had made. We had two of them made actually. They had some frequency response issues that we weren’t happy with and we ended up putting it on hold due to some other things that were higher priority. The frame that wave core uses is easily sourced from several suppliers overseas, so it is the same frame, but a different factory.

This is at our warehouse. It kind of looks like a garage due to the door, but these are large rollup doors meant to allow trucks to pull into.

Great video! They look fantastic, I think I'll steal the copper trim idea😬.

What exactly was the black adhesive you used on the baffle?

Great vid. I love the use of sped up video to demonstrate parts that don't require lot's of detail or explanation.

Maybe I missed it but what black adhesive did you use on the baffle?

It was liquid flashing. Stuck really well to the mdf and seems to have some damping properties based on my tests

It was a liquid flashing I got at Home Depot

I’ve been working on the crossover and think I’ve got something I’m pretty happy with now. The FaitalPRO 6HX150 coax driver is the mid/tweet here. It is a beast to work with passively and this is the most complex crossover I've ever done. The tweeter has two notches and the mid section is 4th order on the top end with two notches.

The mid drops of like a cliff around 1.6 kHz and it doesn't really come back off axis. It's one of the craziest responses I've seen and I have to assume it's due to the cavity from the compression driver tweeter being set back in the mid. Unfortunately the tweeter barely extends down far enough to meet it, which made for some crazy theatrics in the crossover network.

I ended up with a crossover that has a bit of a rough on axis but a really good directivity index. Some of the on-axis roughness still shows up in the power response but it is smoothed out there and mimics an "ideal" 1 dB per octave downward slope.

You can see a small flare in the polars around 2 kHz. On axis there is a prominent dip here and off-axis the tweeter fills this in some with the response of the coaxial itself and a little bit of diffraction so I chose not to focus on trying to get rid of that, as raising the on-axis in this region only made things worse.

If you move from the un-smoothed response to the 1/3 octave smoothing, which is closer to how the human ear typically perceives sound, the response naturally looks a lot better but you can also see that the top octave will likely be perceived as fairly balanced and neutral. This lines up with my listening tests, as nothing stood out as significantly flawed here.

As an FYI, this doesn't include a merged nearfield response or port output, so the woofer extension isn't going to directly match reality. These are tuned to 31 Hz, verified with an impedance sweep.

Wow, now that is a brick wall at 1.6k!

InDIYana Event Website

FaitalPRO 6HX150 spec sheet matches up closely with your measurements > can’t say I’ve seen a spec sheet showing on axis for the LF driver (mid) and at 45 degrees for the HF driver.

Coaxs aren’t the easiest to crossover.

That almost qualifies as a Jon Marsh crossover. You'd need more components on the woofer to fully qualify though.

Yeah, never seen anything like it before.

I hope that we can hear these this weekend. It's a great looking build.

Creative advertising. Technically they didn't fudge the numbers.

I don’t Think I’ll be moving them to the hotel. They’re up in the listening room right now with prototype crossovers all spread out on the floor so Friday night people will be able to listen.

Cool, I'll be there for that this year.

InDIYana Event Website

damn. oah well

So I took some measurements this week in room to see how things were looking because I felt the speakers were still a little bright and some of the attendees at our event felt the same way. Dan thought they were ok but everyone knows his ears are shit anyway

I started with an impedance measurement and everything looked pretty normal and seemed to match my model, but then I took a frequency response at the listening position of both speakers and got this.

After diagnosing things, the series resistor on the mid had come loose, which led to basically no midrange from one side. I still don't know how it was possible to get a very similar impedance between the two speakers with this unless it was shorting in and out, but it definitely changed the whole tonal balance after and made it much more full sounding.

I'm still playing around with a whether or not I want more padding since the sound changed so much after fixing that issue. I think some of the other things I'm hearing are related to the compression driver operating so low in its bandwidth. I took a distortion measurement at 1 m at around 95 dB and got this, which has a large second order spike in distortion in the midrange. Third order is peaking here but still very low.

Awe man! That sucks. Glad you found the issue. I hope to maybe hear these some day.