Dang Bill. That's awesome. For the record you did try to talk me out of it. But I feel like I must build it now. It will be interesting to see how the actual measurements compare to your sim. Looks like a tuning freq. around 25Hz? I was also thinking about making the top gasketed and removeable to adjust damping. I have heard that fiber damping is difficult to simulate its affects. It would make for a fun experiment, except for the size and weight and amount of material and questions from my wife, but other than that I think I will proceed with creating CNC toolpaths. I predict that the tuning will be closer to 20Hz maybe even lower, but that's OK with me. Excursion control. I like the way you figured that driver offset. All things must be considered. Thanks for the encouragement and your attempts at discouragement. You are better at the former than the latter.

What crossover frequency do you think you will be using? If you cross at about 60Hz or so, you will be able to actively choke off some of the nasty peaks and dips in the 100 to 300Hz area that are causing most of the problem in the unstuffed line. These peaks and dips are the most difficult to control with stuffing because of the longer wavelengths.

A 70 or 80Hz xover will also help somewhat to choke off the nasty peaks at 110Hz, 180Hz, 250Hz, 310Hz, etc., in the unstuffed model. The SPA250 uses a 24dB/octave low pass filter that can be adjusted from 40 to 180Hz. So, just to show the differences, I used David Ralph's Winfilters program to generate several LR 24dB/octave low pass filters at 60, 70, 80, 100, and 180Hz. Then I fed the FRD's into OmniMic to make some comparisons. At 110Hz, the 60Hz xover is -21dB; the 70Hz xover is -17dB; the 80Hz xover is -13dB; the 100Hz xover is -7dB, and the 180Hz xover is only -2dB.

Yeah, his designs are pretty legit. We used his weird array speaker for live sound and it worked surprisingly well. Not sure I would use it in my living because they are really ugly.

The TL subs also work really well, but IMHO ported subs are the way to go.

Very nice John. I must admit that I do not know much about the tapped horn. I do see some similarities to a transmission line, lots of overtones, so limited bandwidth, not a big deal for a sub

I got a little bored this morning and I made my sub. I went sealed for the ease of construction and low group delay. I am listening to it now and I like it best centered facing rearward. I don't like it if I can locate it with my ears. It sounds like an add on, disjointed. I have it turned down quite a bit. with the 6 Db boost at 35 Hz. cut off around 60 Hz I think. Not sure, its my first sub. I have heard subs that sounded like someone in the corner was farting at one frequency.

I have heard subs that sounded like someone in the corner was farting at one frequency.

Cut off 60Hz ++

I’ve always felt that the industry ‘std’ 80Hz was selected less so based on sound, and more so on manufactures’ interests. At 80Hz the rollout goes into location frequencies.

Thinking a ported subwoofer was standing by itself in the corner…. Good choice going with sealed / eq’d.

Wondered ... with a raw slab like that and with a split, which they many times do, how do you keep the split from running its course until the slab is in two pieces?

Typically, from what I've seen, once the split makes it's way to the center it would stop. I suspect the above example was while the tree was alive or at least still standing. IE a forked trunk that developed a split in the crotch.

Once I get it flattened I will bondo the bottom side and or tape over the crack. flip over and fill the crack in lifts two a day 1/4 inch or so at a time, unless I invest in some deep pour epoxy. When done you will see that this section was just above the area where it branched off to form three tops. You can see three sets of growth rings. Poor Ash tree either died from crotch rot or the Emerald ash borer, probably both at the same time. In its next life it will be admired by many. Afterall, you know what they say?

Comments

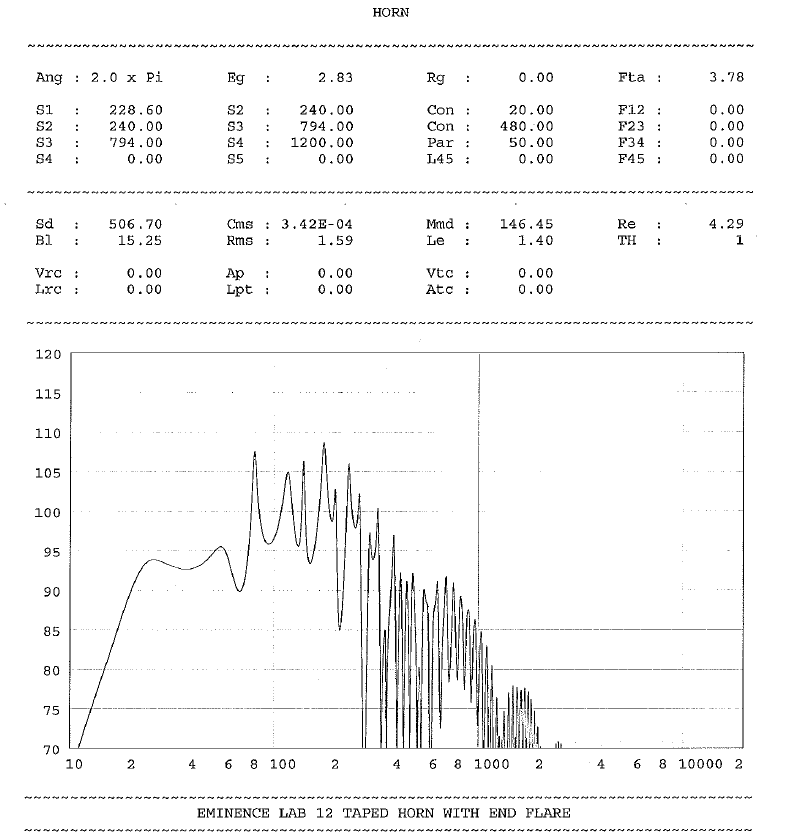

In case anyone is interested in how the model was set up, here is what the enclosure model looks like in the LA TL program:

And the impedance charts:

Dang Bill. That's awesome. For the record you did try to talk me out of it. But I feel like I must build it now. It will be interesting to see how the actual measurements compare to your sim. Looks like a tuning freq. around 25Hz? I was also thinking about making the top gasketed and removeable to adjust damping. I have heard that fiber damping is difficult to simulate its affects. It would make for a fun experiment, except for the size and weight and amount of material and questions from my wife, but other than that I think I will proceed with creating CNC toolpaths. I predict that the tuning will be closer to 20Hz maybe even lower, but that's OK with me. Excursion control. I like the way you figured that driver offset. All things must be considered. Thanks for the encouragement and your attempts at discouragement. You are better at the former than the latter.

Eggie - suggestion:

Leave the top-side of the TL open and place a 1/2" thick glass table-top on it with a gasket to seal it.

Now you have a visual aide/conversation piece that can be covered with a nice walnut top hidden under the couch to assuage the WAF.

What crossover frequency do you think you will be using? If you cross at about 60Hz or so, you will be able to actively choke off some of the nasty peaks and dips in the 100 to 300Hz area that are causing most of the problem in the unstuffed line. These peaks and dips are the most difficult to control with stuffing because of the longer wavelengths.

Originally I was thinking 80, then last night I thought 70 would be about the max for second order slope. We shall see.

A 70 or 80Hz xover will also help somewhat to choke off the nasty peaks at 110Hz, 180Hz, 250Hz, 310Hz, etc., in the unstuffed model. The SPA250 uses a 24dB/octave low pass filter that can be adjusted from 40 to 180Hz. So, just to show the differences, I used David Ralph's Winfilters program to generate several LR 24dB/octave low pass filters at 60, 70, 80, 100, and 180Hz. Then I fed the FRD's into OmniMic to make some comparisons. At 110Hz, the 60Hz xover is -21dB; the 70Hz xover is -17dB; the 80Hz xover is -13dB; the 100Hz xover is -7dB, and the 180Hz xover is only -2dB.

Here is a link to dlr's site in case you want to use the winfilter program: https://www.speakerdesign.net/

This, I even had a fold for this. I thought I gave Craig the plans too.

I am skeptical of the claims by Fitzmaurice's folded horn.

I never built one of his designs, but as far as I know, there were many happy peeps who did.

Yeah, his designs are pretty legit. We used his weird array speaker for live sound and it worked surprisingly well. Not sure I would use it in my living because they are really ugly.

The TL subs also work really well, but IMHO ported subs are the way to go.

Lab 12 horn fold attached.

Very nice John. I must admit that I do not know much about the tapped horn. I do see some similarities to a transmission line, lots of overtones, so limited bandwidth, not a big deal for a sub

Sucker is big though

Half wavelength?

550 centimeter length

Centipeders

I got a little bored this morning and I made my sub. I went sealed for the ease of construction and low group delay. I am listening to it now and I like it best centered facing rearward. I don't like it if I can locate it with my ears. It sounds like an add on, disjointed. I have it turned down quite a bit. with the 6 Db boost at 35 Hz. cut off around 60 Hz I think. Not sure, its my first sub. I have heard subs that sounded like someone in the corner was farting at one frequency.

Looks like the boost should work well for that sub since it tunes pretty high in sealed alignment.

Great minds think alike

I have no idea what that means, I just heard someone say it and thought it sounded cool.

Cut off 60Hz ++

I’ve always felt that the industry ‘std’ 80Hz was selected less so based on sound, and more so on manufactures’ interests. At 80Hz the rollout goes into location frequencies.

Thinking a ported subwoofer was standing by itself in the corner…. Good choice going with sealed / eq’d.

The top is not yet flattened or finished and I think I need a decent Amp with LFE out

Wow! Cool slab.

Wondered ... with a raw slab like that and with a split, which they many times do, how do you keep the split from running its course until the slab is in two pieces?

Good question! Epoxy?

Typically, from what I've seen, once the split makes it's way to the center it would stop. I suspect the above example was while the tree was alive or at least still standing. IE a forked trunk that developed a split in the crotch.

I hate getting a split in the crotch.

Once I get it flattened I will bondo the bottom side and or tape over the crack. flip over and fill the crack in lifts two a day 1/4 inch or so at a time, unless I invest in some deep pour epoxy. When done you will see that this section was just above the area where it branched off to form three tops. You can see three sets of growth rings. Poor Ash tree either died from crotch rot or the Emerald ash borer, probably both at the same time. In its next life it will be admired by many. Afterall, you know what they say?

There's nothing like a nice piece of Ash.