Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

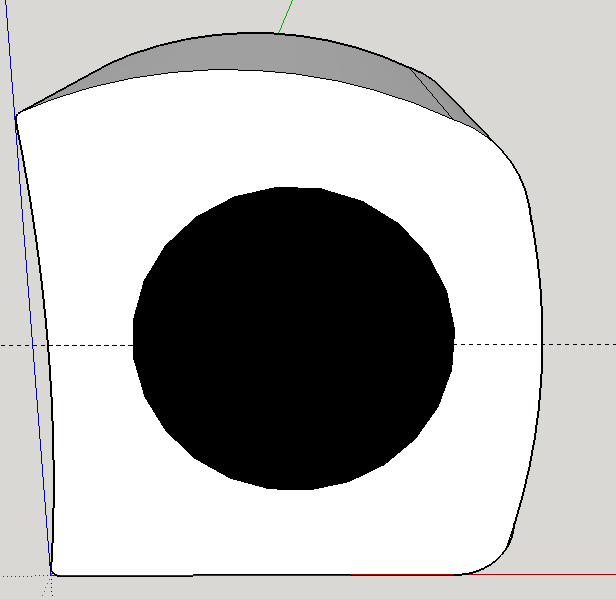

Seas sub build

in DIY

Comments

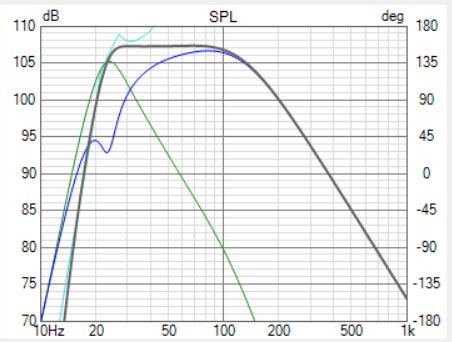

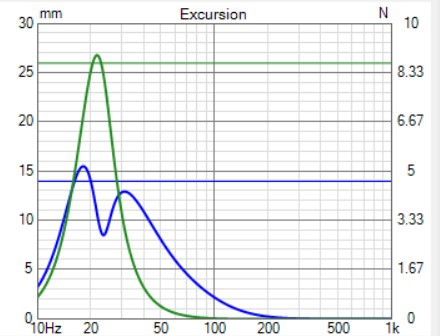

Oh ya, curves

Very odd looking - yet interesting - need build pics for this project for sure . . .

Are you an art grad or something?

Nope. I went to school for electronics, but ended up an electrician. I just don't build many rectangles, I find them boring. For me, building curved boxes is a bit more entertaining .

Your builds are definitely not boring.

I started building the frame work for the pair.

Started gluing up the backs

Love the shape of these and the fact that you didn't HAVE to put the subtle convex arc in the back, but you did it anyway!

What material are you using for the curves? Can't make out from the pictures, is it Hardboard? Also interested in seeing how you go over that pretty small radius bend.

It's Masonite/hardboard. The small radius areas will have to be kerfed.

kerf hardboard or plywood/mdf. The thing I find daunting is matching the thickness of multiple layers of hardboard and say mdf. The transition from the kerfed sufface to the multiple layers of hardboard.

belt sander

For builds with a tight radius such as this I use 1/8' Masonite and use a high STB blade, so the kerfs are triangular and not square. It makes for a smoother radius.

how deep do you cut 1/16? do you havea link for a suitable blade. Haven't seen anyone using such shallow cuts for kerf. usuall they are all MDFs or Plywoods. Defineltely interested in your build and methods and if you can post lots or pictures or videos would be great!

I use a Freud LU80 blade and the depth of cut depends on how tight the radius is. Here's a couple of photos of a sample cut.

Thanks!

That's a bit too Precise!!! Table saw or radial arm saw?

I use a radial arm saw, but for wider pieces a simple jig and a circular saw would do the trick.

Do you have any ideas for the Jig - namely how to keep the spacing between cuts consistent. I'll kook around for some kerfing videos or instructions

I honestly don't worry about perfect spacing, I just eyeball it and run. The larger the radius the less it matters.

I kerfed some 18mm Baltic Birch some years ago. I found that a 5/16 spacing gave me the radius I wanted.

Obviously, the tighter the spacing, the smaller the radius you can get.

That Seas driver is very good. These subs should be spectacular. Can't wait to hear what you think of them.