Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Doctor Diffraction: A donut shaped high end loudspeaker.

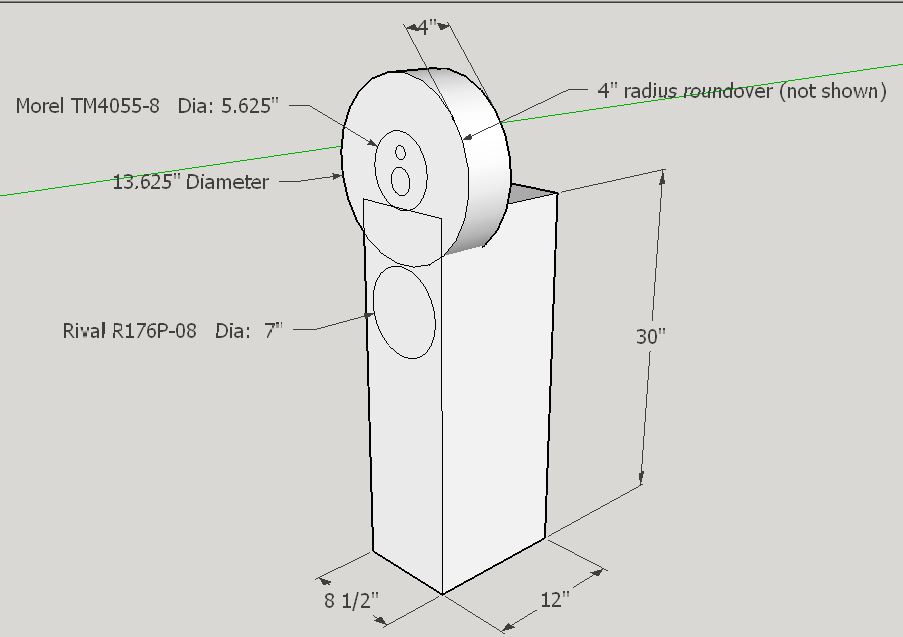

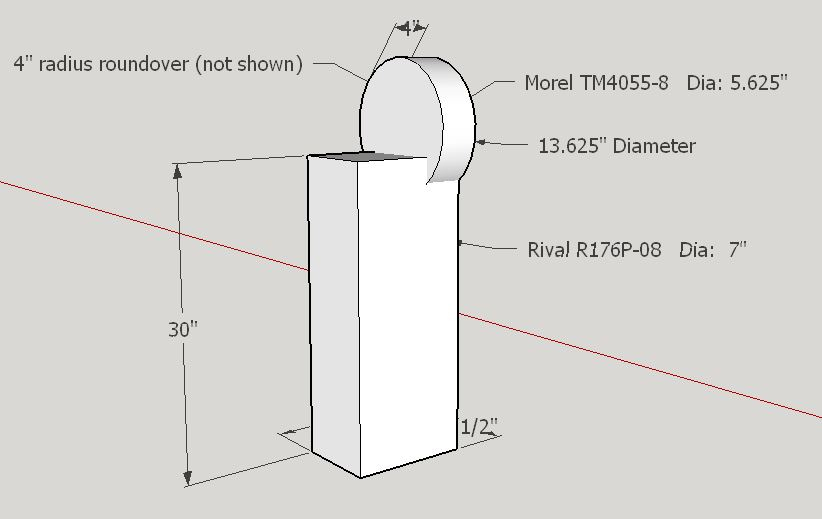

For this project I will be creating a high end 3 way floorstander using the Rival R176-P-08 paper cone 7 inch woofers and the Morel TM4055-8 tweet/mid's. These woofers were used by Ben in his Fenrir speakers and by Javad in his Rivalries with good results. The Morel drivers were used by Paul K in his Cornetta speakers (MWAF 2019) with very good results as well.

https://www.parts-express.com/morel-tm4055-8-2-midrange-and-1-1-8-tweeter-speaker-plate--287-038

https://rhythmaudiodesign.com/products/r176-p-08-carbon-pulp

My plan is to mount the TM4055 in the center of a large 4 inch thick donut style baffle using a 4 inch radius roundover along the top 80% of the baffle. My drafting skills are not the best, so the drawing does not show the actual roundover (sorry). The radius will taper down to 3", then 2" and finally to 3/4" where it merges with the lower box. The lower box will have a 3/4" radius roundover (not shown). I am going to grind out the roundovers with my belt sander, forming the radius in stages using guide lines and cardboard templates. JR did a good job of rounding the corners and facets on his small bookshelf speakers a few years ago, using only a beltsander. Seems like a good plan and it should work as long as I develop a good spherical rhythm as I sand back and forth to reach my layout lines. I will, of course, be wearing an M95 dusk mask and using particle board instead MDF to keep the dust down.

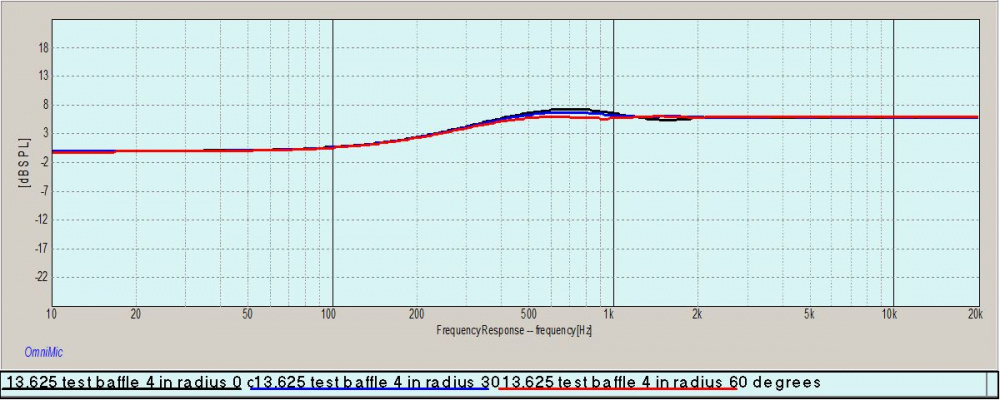

What I am trying to do here is to reduce diffraction ripple above 1kHz as much as possible. Attached is a model of the expected diffraction using a square 13.625 baffle with 4 inch radius roundovers. I used Jeff B's BDS program to create this model. My baffle be round, but the results above 1kHz should be similar. The remaining lower frquency diffraction bumps should be easy to handle in the xover (approx 800Hz).

I'll be picking up lumber next week and will stop back here from time to time with pictures. As soon as the cabinets are done, I'll be running up a full set of measurements. Stay tuned and thanks for reading. Comments and feedback are always welcome.

Comments

InDIYana Event Website

Ron

Thanks, Ron. I agree with what you are saying, but I think you are misunderstanding what I am trying to do here. I am NOT putting a single driver in the middle of a round baffle with sharp edges. I am putting two drivers, slightly off center, in the middle of a circular baffle that is transitioning into a spherically shaped baffle. The huge round-overs make a big difference. A circle begins to transition into a sphere when you make the circle and the round-over radius extremely large. In addition, a spherical shape is superior to a conventional rectangular shape because it helps to reduce the diffraction ripple created by the top two box corners.

Thanks for the offer, Ken, but I have already cut the wood. I thought about doing this on a lathe, but then I would have the problem of filling in the lower section where it connects to the lower box. Also, the lower section edges slowly transition from the large to small round-over, and this cannot be done on a lathe. If my belt sander approach fails, I'll let you know. CNC is probably the only other way to do this.

Picked up some lumber: two 6 ft long particle board benchtops (Menards). They are 2 feet deep and 1.14" thick (1-1/8" nominal). I revised my plans. I boosted the radius from 4" to 5-5/8" and changed the overall donut diameter from 13.625" to 17". As a result, I ran out of lumber, so I will have to go back for more.

Too late. Name is already "Doctor Diffraction". For my next project, however, I was thinking a small 8" two way using up my restored "grab bag" RST28F's and the pair of SD215A-88 8" woofers I bought from Craig. With your permission, I would name them the "Zonkers". Then we would have the Zingers, the Zangers, and the Zonkers. How does that sound?

I have two of these. Picked them up from my Dad's workshop when he passed away 18 years ago. I often prefer these over a standard tape measure.

Top heavy: Yes, indeed. I'm concerned about this and am hoping for the best. I weighed the large donut on my bathroom scales: 30 lbs!!!! I'm hoping that after I hollow it out, cut off the bottom, round the edges, etc., that I get it down to about 10 lbs or so. Otherwise the speaker may fall flat on its face!!!!

I'm not Ben but I think your name idea is fun. I would be very surprised if Ben didn't agree.

InDIYana Event Website

I reserve Octozaenger.

For future projects you might want to consider pink foam. It can be painted with acrylic paints and is both cheap and lightweight. Even hand sanding can remove material quickly. This might make it so you can model the idea and measure before going through the work of making it out of wood.

Thanks for the heads up, John. What was your xover frequency? I will be targeting 800Hz or so to the 2" midrange driver. If I run into problems, I can substitute my pair of Esoteric 7" woofers and give them a try. The flange on the Esoteric is identical to the R176-P.

Good idea. Do you mean the pink insulation foam sold in 4x8 sheets in 1 or 2 inch thicknesses? Did not know you could paint or sand this material.

My drafting skills are not the best. On the first picture, I simply created a box and then I created a donut. I merged the two drawings, which makes it look like donut is cut out. My plan is to cut a flat spot on the bottom of the donut and bolt it to the top of the box. I might cut the corner out on the top of the box to make it look better.

Cool! Wish I would have thought of that. Zonkers is pretty good too.

I forgot to mention one other thing about the Olson paper, diffraction, and cabinet shape. Here is a link to the original paper:

http://www.aes.org/aeshc/pdf/how.the.aes.began/olson_direct-radiator-loudspeaker-enclosures.pdf

My speaker will be a 180 degree hemisphere; not a true 360 degree sphere. As referenced in the AES paper, the diffraction for the hemisphere shape is actually smoother than the sphere above 2kHz. The spherical shape is superior below 2kHz. Olson did not mention why this occurred, but I think this happens because sound waves follow the surface of the sphere, traveling all the way around back to the front side again and this, in turn, is picked up by the microphone as HF ripple. With a hemisphere, the sound waves diffract at the exterior sharp edge which causes higher lower frequency ripple instead (based on the size of the hemisphere).

Olson only measured out to 4kHz, but I think these measurement differences may be important, because we are very sensitive to phase differences in the high frequency area.

I revised my donut drawing again to remove more material; now down to 18 lbs. each. Before gluing up the rings, I plan to chamfer the internal ring edges at 45 degrees to get rid of even more material. 18 lbs. is still way too much. I'm hoping the big 5.625" radius round-over will get rid of another 4 lbs.

**Note on TM4055: If you use this tweeter/mid in a project, do NOT cut a 4.76" mounting hole as suggested. Cut a smaller 4.5" hole and then add "bump-out" style clearance "ears" for the chambers. As shown in the photos, I used a 1.5" diameter bump-out for the tweeter chamber and a 3" diameter bump-out for the mid chamber. Otherwise, if you cut a 4.76" hole, the mounting screw holes will be too close to the edges.

https://www.jfcomponents.com/

Nah. You get the credit for that one.

Glue-up, templates and guidelines:

Handheld 3x21 Rockwell belt sander. Picked up new 50 grit and 120 grit belts today. Yes, indeed, lots of sawdust. Should be fun!!!

The plan: I will be clamping/mounting the donuts in my 45 degree angle sled and bringing the edge down to the guidelines in a total of 5 stages. Double checking the round-over consistency along the way with the templates. When I get close to the final round-over guidelines, my plan is to glue sandpaper to my templates and do the final sanding by hand.