Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Second Summer Project

So this is a project that has been simmering for quite some time now. The final driver complement and overall design concept has changed considerably from when I initially cut baffles several years ago. I kind of lost momentum on design work for awhile there, but have been fired up lately.

Originally, the design was to be a basic 2-way with the Max Fidelity 6.5" and a Seas tweeter. It was intended to be a team project with Mrs. JR - but she has decided against doing much with it. However, when I was going through my stash, I showed her the Dynavox honeycomb woofer and she said she likes how they look and I should really do something with them.

The tweeter is still the Seas (I forget what exact model, to be honest - but I believe it is the H0881) but I was fucking around in the garage one afternoon and decided to stick the Visaton 148mm waveguide on it. It fits reasonably well, had to over-drill the holes in the tweeter faceplate and the throat transition isn't perfect so I do expect some errata in the upper range but quite frankly I just don't care about the top 1.5 octaves these days. It should still offer the advantages of a waveguide, and the tweeter despite a low Fs drops like a rock below 2K so the boost of the guide should also be of some benefit there, as well.

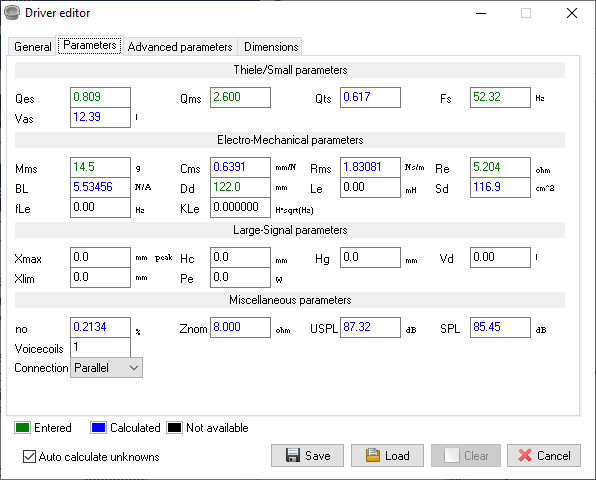

Others have pointed out Dynavox generally do not measure too accurately, and here is one of my two after an exercise routine:

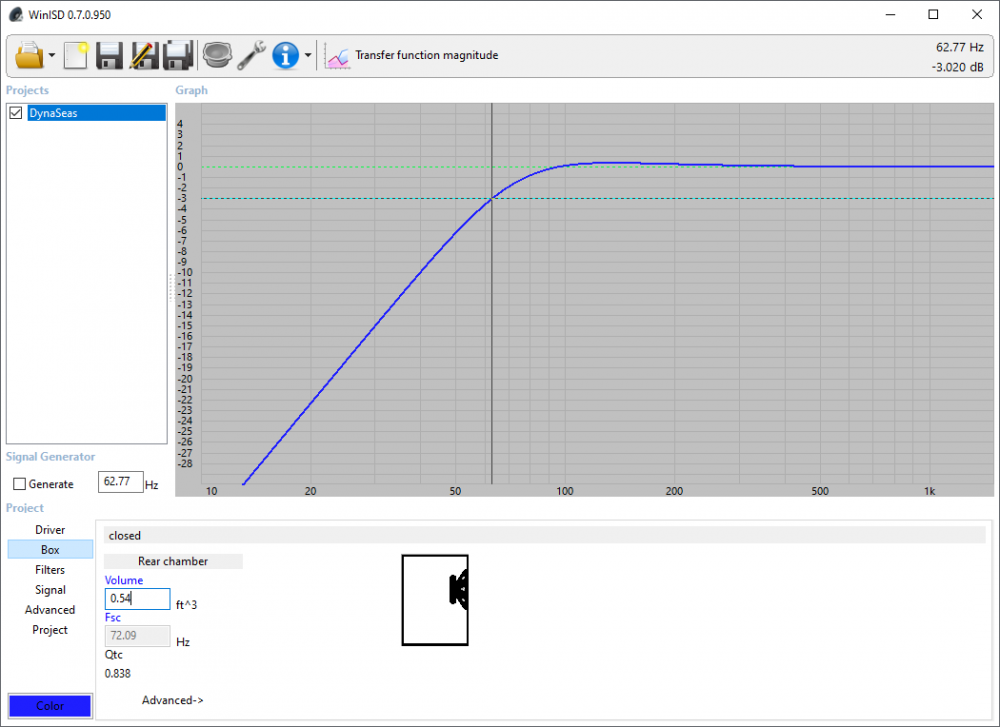

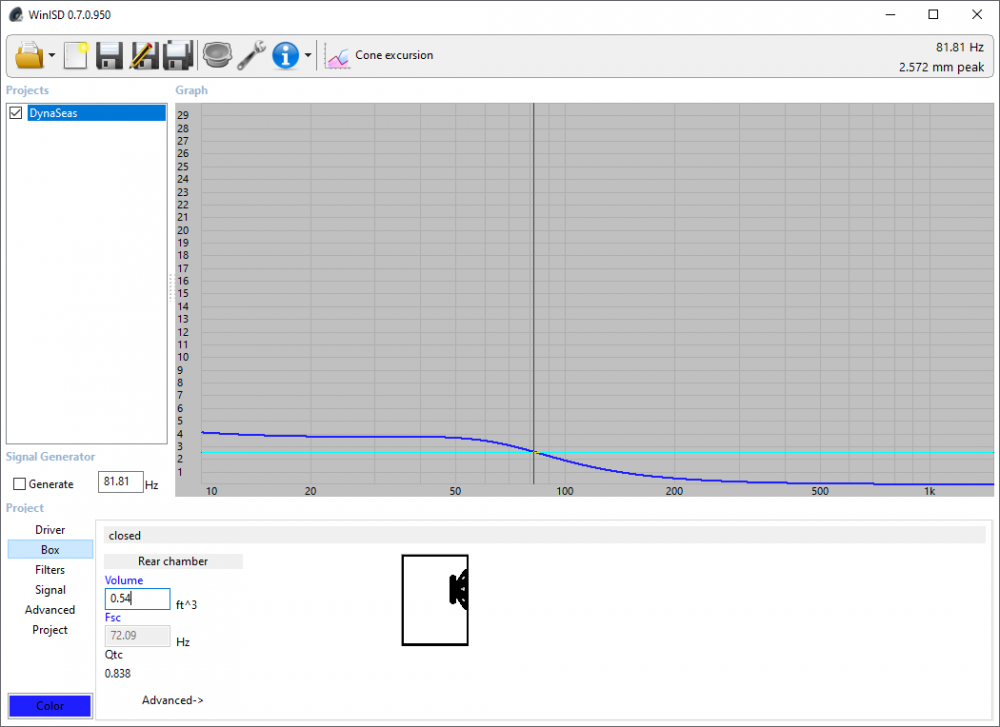

This will be built into a PE 0.56 cubic foot flat pack, here is my modeling. Sealed, medium stuffing. Should do OK, if not exactly earth shaking:

Excursion at 10W indicates it won't offer much in the way of output - but having heard people beat hell out of Dynavox in the past it is my belief they stay linear beyond rated Xmax and suffer very little from power compression so I think it should be a bigger speaker than the wimpy Xmax would have us believe.

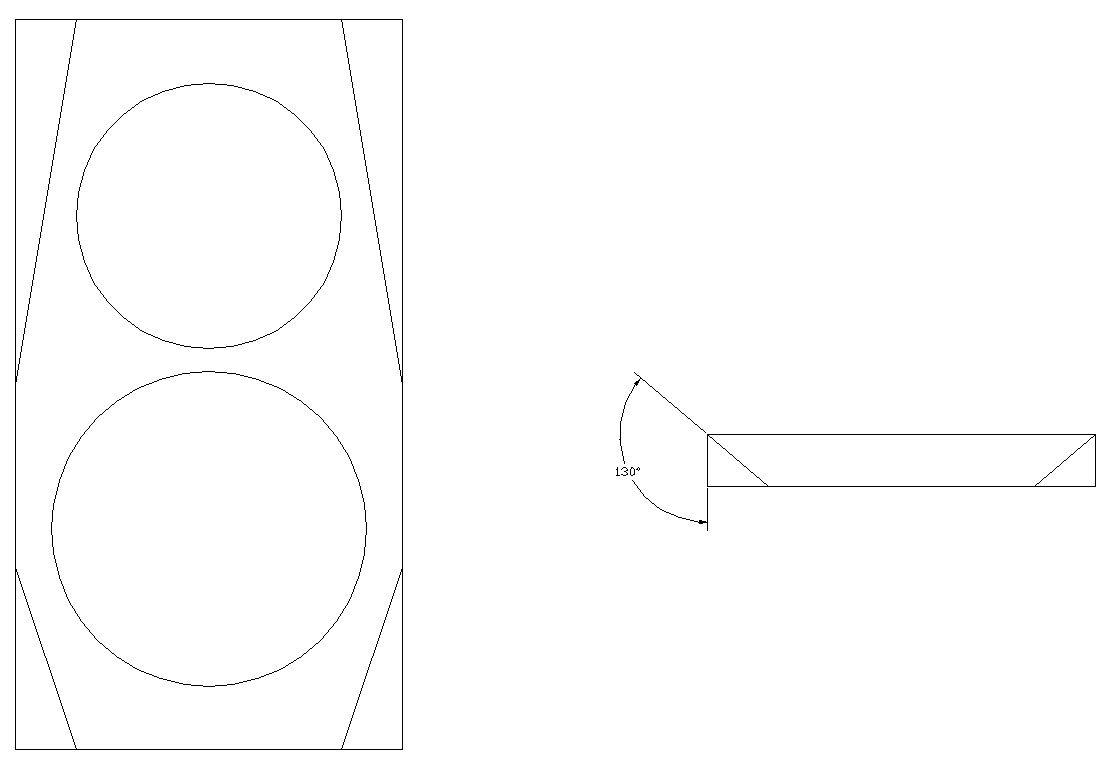

Now, since one goal of these is to offer very low linear distortion and good off-axis, I will be doing a faceted baffle. Nothing too fancy, just enough to create a lot of different distances from center of tweeter to baffle edge. I may smooth the facets after cutting, have not decided yet. Depends on how ambitious I am that day.

Baffle will be made of particle board stair tread from Menards. Experience has taught me this is an excellent choice for cabinet material. The outer 1/8" or so is rock hard and it is overall much stiffer and denser than the basic particle board found in handi-panel sizes, for example.

So anyways, once this and the tower are more or less finished up I have plans to build a pretty high end design for the basement. Hopefully one of these summer projects makes its way to Iowa this October. The towers will likely be going to some friends of ours, and these monitors may actually end up serving in some capacity at a local studio.

Anyways, happy Wednesday.

Comments

Are you trying to take the title of "the energized bunny of speaker building from Craig".

Craig are you gonna take that?

Is the face plate of the Seas tweeter removable? You might get a better throat match with it removed. Just a thought.

I'm trying to remember if I tested that way of fitting or not. Hmm.

Pretty sure all standard line dome for SEAS are glued to the faceplate, I remember because getting a new voicecoil means getting a new faceplate as well.

Got the oversized baffles glued on today, just a few minor items to button up on the other pair.

One nice thing about this project, if I do not like the Seas performance in this waveguide - there are a lot of tweeters that will more or less fit it, some of which I already own.

Tomorrow I will flush the baffle, cut the facets and machine the driver openings.

You are going to finishthe summer projects before summer at this point. Keep it up.

I have one that will likely take all summer to complete - wanna get these out of the way.

Now, if I'm lucky the Seas will play nice with the waveguide. If not, the beast mode DX25 is here, a 32mm O-ring and a quick mounting clamp solves that.

Caution: Naked speaker boxes.

Damn, JR - those are going to be some nice looking speakers. Those Dynavox woofers have a cool, almost 3D look to them.

Speaking of which... did you ever do anything with those Dynavox drivers you bought from me?

Yeah - one pair were in the speakers I brought to Ankeny in 2018. That design needed a touch more BSC, but those are decent woofers, especially at the price I paid for them!

Did those, by chance, originate with me Craig? I sold a pair of truncated Dynavox to someone as well. Hmmmm.

Busy day DIY'ing, time for beer. Gonna grab some 3-2-1 tomorrow and get these primed. I heard it's sandable.

Negative. I bought a quad when they were deeply discounted, then sold the quad to Tom for a bit less. He's been so generous to me with vacuum tubes and such....

Not sure about the water and oil based but the shellac is

Decided Duratex is as good as any "primer" out there. First (very heavy) coat. I love summer Duratex, shit cures fast. It is almost 90 here already. This will be sandable tomorrow, I think.

How much of a seam will it hide? Will it ghost later? Will lacquer paint stick to it?

I don't know, I don't know, and I know automotive enamel adheres but have not tested lacquer.

I love the effect of what those baffle facets do. Not just sonically reducing defraction but it optically makes it look like the baffles are somehow convex. Nice work Brother!

So far, so good on seam concealment. Will sand and recoat tomorrow. Sand again maybe Tuesday and spray filler primer. That will take a while to cure, then top coat. Will know final answer on seams in three-four weeks I think.

At first glance of those woofers one expects to see bees hanging out on them

Sanded off first heavy coat of dirtytex just now. In the past, my best luck with seam hiding has been use the end grain swelling to my advantage. I've never used Duratex in this fashion, but it is obvious from this picture that swelling contributes to seam broadcasting.

All end grain should now be largely sealed, so off to next step.

The swelling is fairly significant, as demonstrated by the pattern reveal on the baffle.

So a few days have passed, and I believe the swelling is finally stopped. I applied another round of glazing putty to the seams on the top and where the baffle attaches. I am not concerned about the bottom or the back. I am now in strict hand sanding land, and will likely have to do at least one more skim coat of the putty.

I will be finishing these with the same satin black I used on the towers, albeit with a foam roller this time to keep texturing to a minimum. See how it goes.

Have you considered covering them in shellac first. The water based paint probably making the swelling worse.

The only water-based I used was dirtytex, that should be completely cured at this point.

Ok, it was just a thought. Particle board and water don't mix.