Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

F6 + RT1.3WE

Thought I'd start a thread documenting my latest design project. A 15 liter 2 way with the HiVi F6 midbass and Dayton RST28F in a Visaton WG148R waveguide.

I just finished gluing up the boxes, mounting the baffles for flush trimming and round overs. Next up is to machine the driver cutouts and rebates. Weather should be perfect for that this weekend.

Anyway, I know we all like seeing pictures so:

Comments

Yaaahhhh! Zebrawood🤘🏼

Please, let the F6 rolloff be allowed, even though it looks lousy, and treat the 900-1100Hz 'issue'. You'll be happy.

InDIYana Event Website

I tried a little BLO/satin-poly/thinner mix on a scrap piece and it looked great! Nice grain detail and depth with a warm cinnamon color. At this point I think a satin finish is the way to go. Some species look great with a polished high gloss finish. This one seems better with a more natural satin sheen.

The removable MDF baffle will receive a cool "slightly textured" finish I used on a recent project. It compliments the black driver frames and waveguides, but is pretty benign. Don't need a baffle finish to "pop" when you have a bright yellow woofer cone staring at you

Thanks Ben!

You truthfully can xover the F6 at 4kHz if you so choose, but 3.2-3.5kHz keeps the wonderful midrange in check.

InDIYana Event Website

You can see the effect here:

InDIYana Event Website

Hmmm? If the F6 really has that great of midrange and likes to cross at 3k then there really is no point in me using an RST28F in a waveguide. Need to rethink this. I have a nice pair of RT1.3WE's... that could make a nice detailed speaker for under $200 in driver cost

Pulled the trigger, made the switch to the RT1.3WE tweeters. No looking back now LOL.

Baffles are fully machined, sanded, and primed with 1-2-3.

First coat of BLO/turpentine/satin-poly has been applied to the veneered enclosures.

I think you've made a great choice!

InDIYana Event Website

Look Nick, the backs and bottoms are even finished

First coat of primer. Lots of sanding to do.

Gotta love a pretty bottom!

These are lookin great, I really like the veneer.

Very nice! Especially from someone who said he didn't like to build cabinets!

Thanks Tom! I do seriously enjoy taking measurements and designing crossovers the most. Wood working is just a means to an end. That said, I finally have my table saw dialed in so well that, doing 45 degree miter joints is much easier than butt joints. A brand new sharp blade yielded zero issues (tear out) of the veneer. The corner joints are so near perfect that I didn't even use clamps. Just painters tape to hold all four corners while the glue dried. The rear panels are rabbited in, so there is about an 1/8" of exposed MDF around the rear parameter. These are built from some of that pre-veneered MDF my neighbor gave me. And Dave Fred's 3 part finish is fool proof enough that even I can succeed

Wow, there is a serious shortage of spray paint at the big box stores. None of them in a 50 mile radius has the color/texture paint I'm looking for. Luckily a small, local Ace Hardware had one can ($2 more than the box stores).

I guess I should clarify my statement above a bit. I still find it enjoyable to plan out and cut speaker panels on my table saw, as well as gluing up and clamping them together. What I'm so tired of doing is pretty much every process that involves my router (driver rebates and through holes, flush trimming, and roundovers), applying veneer, any and all sanding, foam brushes and rollers spray cans (all the finishing steps). If I could find someone close by who is good at all that stuff I would happily trade my xo design work for a pair of boxes here and there. Probably not going to happen 🤔

Looks like a promising project. My son has my F6 speakers (the Emeralds) at college. I think they will work will with the RT1.3's, much like the SB15's did in the Keramiskas.

Sehlin Sound Solutions

So I totally screwed up last night! I had painted the baffles with a lightly textured, flat black paint. They looked great, but the surface finish felt like about 220 grit sandpaper, basically a PIA dust collector. So I decided a few light coats of satin clear would fix that and look pretty nice. BIG MISTAKE! They ended up looking like a very bad DIY paint job (i.e. not much better than a novice project with bad orange peal).

Started to sand them down today for a redo but the clear coat was just gumming up my paper. They're sitting in an oven at work right now curing at 250 F.....

I hate finishing speakers

That's the hardest part ... unless you're NIck.

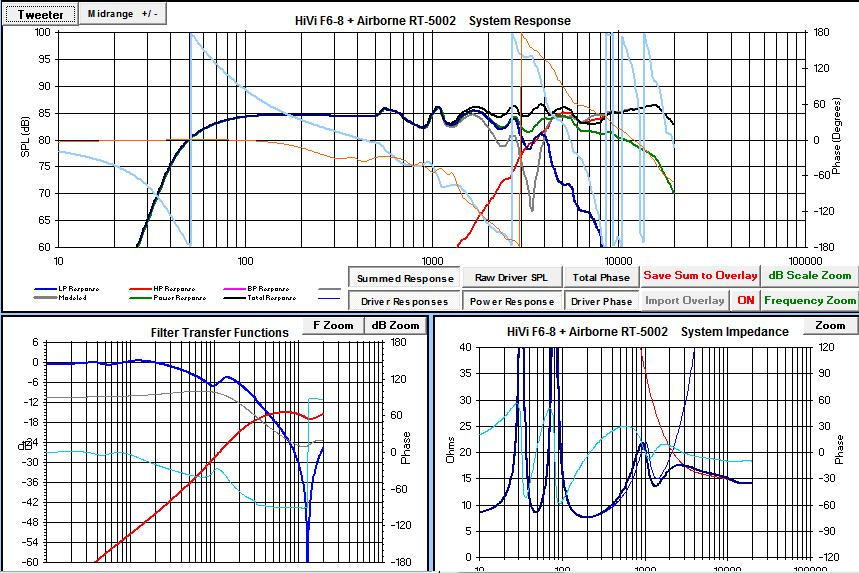

Just completed all of my on and off axis measurements for this project, plus on axis distortion. Happy to see the FR of the F6 is nowhere as nasty as I've seen posted else where on line. I measured 35 inches from baffle on the tweeters' axis. Was able to gate at 4.78 mSec in my room. The F6 issue around 900 Hz is obvious and will need to be taken care of with the passive crossover. But the response from 1 to 3kHz is really smooth. Nothing to worry about there. Even the cone breakup around 4.5 k is not terrible. The RT1.3WE didn't disappoint either. I have high hopes for this project. They will be demo'd in Grand Rapids for sure.

Decided to sand down the baffles and give them a new finish. I like how they turned out. Time to get busy with XSim...

I used 0.47mH/47uF/8 ohm notch for the 900Hz honk.

InDIYana Event Website

Craig always uses Speakons, doesn't everyone know that?

InDIYana Event Website

I like Speakons.

Would you entertain a bronze color for the baffle? The grey kinda battles with the browns of the zebrawood to my eye....just throwing that out there.

Or even a Brass color. Could always go for the Rustoleum dark cherry I used with the F6.

InDIYana Event Website

I'm not painting those stinking baffles again...

So my very artistic daughter got home today and saw these for the first time. She loves the gray baffles, perfect contast that makes the drivers and zebra wood pop! (her words, not mine)... "So I got that going for me, which is nice" (Carl from Caddy Shack voice)

She initially named them the "Sunnyside Ups" because they remind her of how she likes her eggs cooked. After some thought she changed her mind because the marrijuana/canibus stores around here are named "Sunnyside Dispensary" and told me they shall therefore be called "The Yellow Jackets". Seems like a good name to me. I've worked up a preliminary xo design. Good simulated FR and phase tracking. Time to dig through my xo parts and see if I need to order anything.

Well said