Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Rack 'em up!

I think this is considered on topic - it's audio related and DIY!

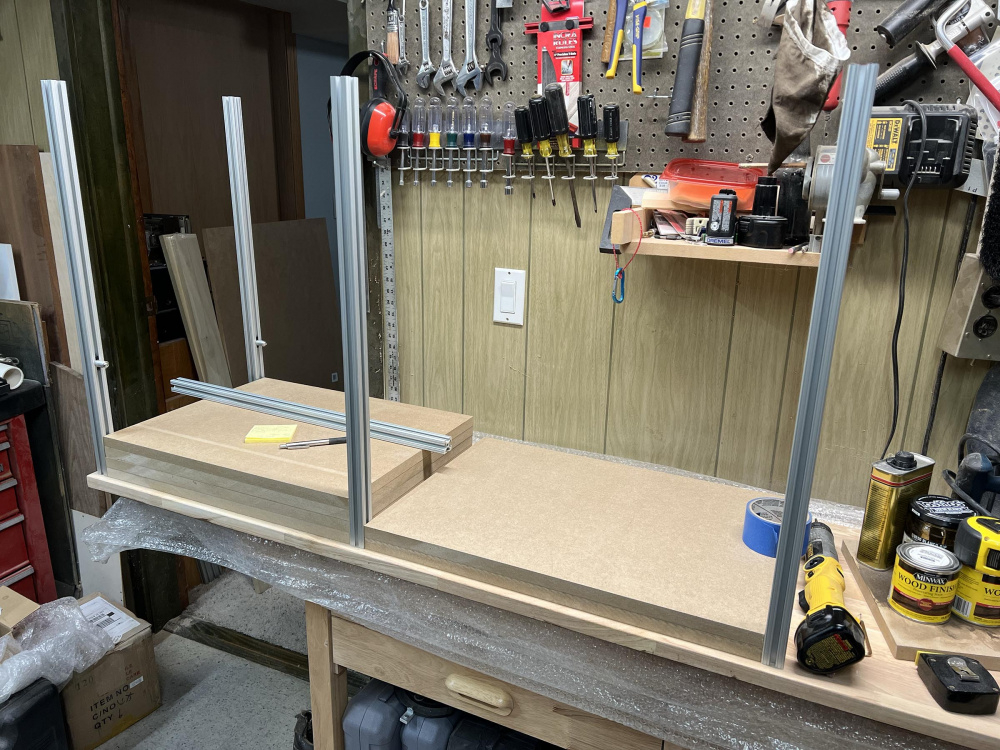

I have a fleet of vintage (mostly Pioneer) receivers and decided I need something a little bigger & better to house them than the old black bakers rack I've been using. I always wanted one of the big Salamander racks, but the cost for a triple wide was pretty steep. Seems easy enough to DIY.

I bought the aluminum extrusions from 80/20 a while back. I found some long hardwood (turns out it's rubber wood) "cutting boards" at an online restaurant supply place last month for a reasonable price. They were designed to drop into commercial bakers racks and I ordered two of the 18 x 72" versions for around $220 shipped. Turns out these are sure not furniture quality and one had some dents and scratches on one side. But at least they are solid wood, unlike the Ikea tops I was also looking at. These look remarkably similar to my Harbor Freight workbench. I'm using a dark stain, hoping it will hide the contrast between some of the pieces they spliced together.

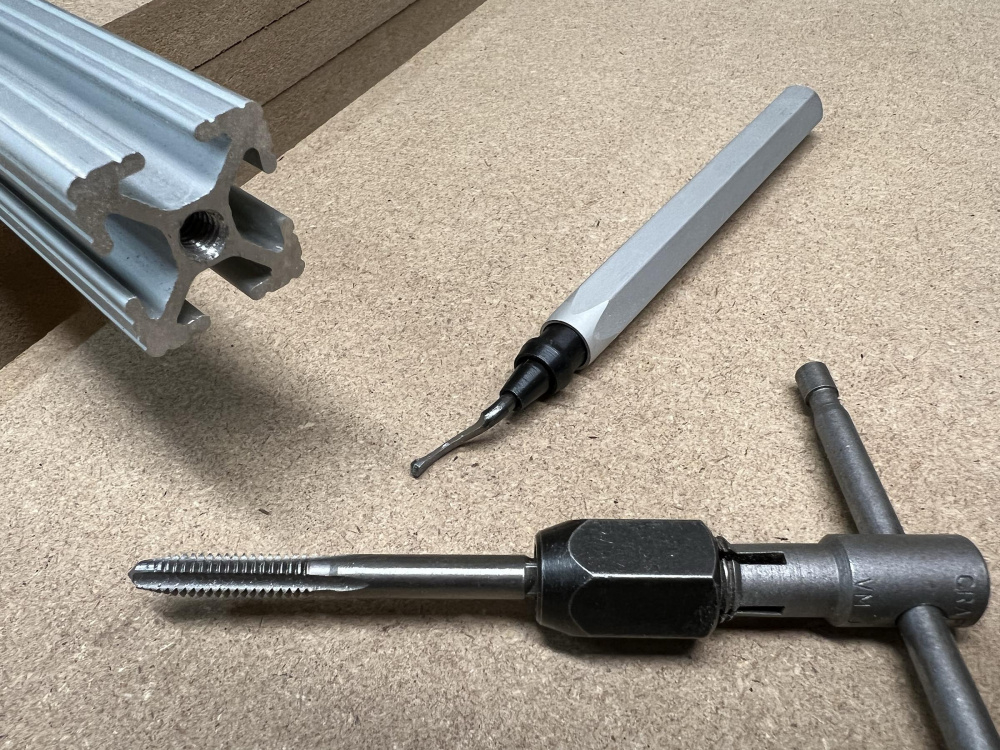

My hands ached after tapping 16 1/4-20 holes. I took it slow and used lots of cutting oil - no broken taps!

Got the shelves all cut yesterday. The crosscut sled made that a walk in the park. They are wider than usual in the center for some of the bigger receivers. I'm using aluminum standoffs as shelf supports. They'll be somewhat hidden by poplar front and rear strips on each shelf. I'm hoping that will also keep the shelves from sliding back and forth when loading it up with equipment.

Comments

That 80/20 stuff is freaking bad ass! Lucky me, a good friend has a bunch of it and we built a work bench out of it for my garage.

I'm sure your rack unit will be stellar!

Now that's a workbench! I'm just using the 10 series extrusions and it seems pretty sturdy. I bet you could park a Harley on yours!

I'd be trying a cordless drill on low speed to tap all those holes with a tap that large. As long as you start the tap straight and don't bottom it out it should be ok.

Ron

I drive right by 80/20 everytime I go to InDIYana. It's right there on Hwy 30.

Looks great Tom!

I thought about that but didn't want to push my luck - which isn't good when it comes to these kinds of things. The extrusions aren't all that expensive, but if I snapped off a tap in one, it would be unusable and I'd have to wait on a replacement. It wasn't too bad, just slow going. I listened to some tunes on Iowa Public Radio and just kept turning that T-handle. How's that for an exciting Friday night?

I've had worse Friday nights Tom

I usually use a cordless drill to tap, or at least get the tap started good and straight.

Isn't that not the best plan as taps are square shafts, and drills are made for circular, triangular, or hexagonal shafts?

InDIYana Event Website

There is a type of tap meant for use in a machine or drill, they're called gun taps. You just drive them straight in, no reversing to break the chips.

I used some 80/20 remnants to make an audio rack a couple of years ago. If I had your skills, Nick, I would have attempted doors, solid sides, etc... but I'm very happy with the functionality in any event.

I hand-tapped all the center holes so I could attach the top and bottom boards with flat head screws. It wasn't particularly difficult using cheap taps from Harbor Freight.

Sehlin Sound Solutions

I see Scooter adheres to my speaker-chic decor mantra.

InDIYana Event Website

That's pretty much what I'm building. I'm not planning on having doors, but I will have side panels - just 1/4" oak ply dropped into the slots.

The square part of the shaft is short so you just chuck up on the round part.

Ron

They also make adapters for machine use, as well as tapping heads that automatically reverse when you stop applying downward pressure.

The cabinet looks good!

I just naively assume I can build anything, and have a willingness to purchase whatever tool I need to get it done, but usually fail several times along the way.

But you always WIN in the long run! That's true DIY in my book.

Great project Tom!

I did check the prices on those...more than my entire project! A good friend has a couple nice Tapmatic heads, but he's out of town right now.

I decided to take Ron's advice on using the drill to tap the short leg pieces. I have a little extra piece of extrusion, so I figured if I screwed it up I could cut off another piece and still proceed. Worked like a charm as long as I cleaned the chips off the tap with a wire brush every so often. I had this little jig built and all 16 threads tapped in under an hour. If had to do it again, I would look for a spiral tap that would pull the chips up and out the top.

I decided to use a 1/4" strip of oak on the face of each shelf instead of the poplar. I figure the side panels are oak, so at least that will match. I cut some thin scrap 1/2" MDF strips that will be glued underneath each shelf to act as locators. If everything lines up, the shelves should drop in and lock in place.

Next stop - sanding and staining!

The rack is done! I decided not to insert the side panels to help with pulling cables through and dissipate some heat. Well, that and the fact that I forgot to stain them....

Here's my little shrine to the Silver Pioneer!

Dude, that is one hellava shrine!! Looks fantastic🤘🏼

Wow, just a cool collection.

Awesome!

Wow man. That is impressive as all hell. That vintage equipment is worth a fortune these days.

Thanks! There's quite a bit more gear scattered around the basement. I really need to build a few smaller racks to match this one.

Yeah, prices are a little ridiculous right now. And they are only going to go up as through-hole components are slowly phased out. I'm recapping & replacing problem transistors in all my vintage stuff while you can still get parts. That ought to keep me busy for a few more years!

That is a nice Pioneer collection. That SX-xx50 series was built like tanks. The first receiver I bought as a teenager was a Pioneer from the fluoroscan era. Great job with the rack.

Sehlin Sound Solutions

Thanks! I repaired a Marantz AV600 preamp (circa 1998) for my son a few weeks ago. On the bench right now is an SX-727 (1972-74) for a complete restoration. The difference in build quality is staggering.

Tom, you collect silver like I collect drivers... Awesome!

Post deleted

I haven't had to replace a pot...yet. For something like that, there are a few Ebay stores that look reputable. If you are on Audiokarma, you can post that you are looking for a specific piece and sometimes someone will have a spare to sell at a reasonable price.