Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Project "Monoculus", Versabox project #3...

The name arises from the daisy flower affiliation.

These are the new W4-2315 4.5" coaxes from Tang Band. Datasheet here:

http://www.tb-speaker.com/products/w4-2315

They aren't even available state-side yet. These came from the TB president and she asked me to build something, show it off, and publicize all the data.

I'll be pairing them with the w6-1139SIF, as I have a quad, but only one woofer per cab. Datasheet here:

http://www.tb-speaker.com/products/w6-1139sif

Xovers tentatively 500 and 2.5kHz, but we'll see. I'm hopeful these sound great!

Stay tuned...

Comments

Interesting design detailing. Looking forward to learning more.

Ben, are you setup for full 0-90 measurements?

I can, doesn't mean I always do it. The coax portion will likely force my hand this time.

InDIYana Event Website

Of note for differences in the concentric style drivers...

The W8-2314 and W6-2313 used several neo-slug magnets around the perimeter for the underhung woofer. The new 2315 has a single Neo ring magnet.

The 6 and 8 both also have vented frames around the spider inside the frame, or even holes cut through the spider. The 2315 has neither of these that I can tell.

The 2315 has a 20mm tweeter, whereas the others have a 25mm.

InDIYana Event Website

20mm tweet has broader dispersion than the 25mm?

What about cone shapes? Do they differ at all?

How will this W4 2315 compare to the new SBA 4" AI coax? --> https://www.madisoundspeakerstore.com/coaxial/sb-acoustics-sb12pacr25-4-coax-4-round/

inquiring minds, and all that - looking forward to your thoughts/findings.

The TB will have a better motor for sure. Probably a better woofer portion.

The SB is cheaper, though.

I agree with JR.

All of the TB cones are shallow bamboo paper, and the tweeters are all concave domes for better diaphragm curve matching. Yes, the 20mm will have better dispersion, but will not play as low. In a 4.5" mid, this is likely a non-issue as the mid will play higher.

Big difference between the SB and TB, is that the TB has a 20mm concave dome tweeter, and the SB has a 13mm dome. The 13mm will not play as low, and IMO, could have problems meeting a 4" aluminum cone midrange. Paper would be easier and more forgiving. The surrounds are also different, where the TB has a lower and shallower tangential style with edge ring-reducing ribs, and the SB has a conventional roll surround. 3k is likely the lowest I'd xover in theory on the SB, but HD sweeps will possibly reveal a higher cutoff is necessary. I may run into that on the TB too, but I'm not expecting to need to be higher than 3k.

InDIYana Event Website

Super good insight, Wolf - thanks for this response - still looking forward to your findings.

I know nothing about you nor your background but I assume you are a force within the audio reproduction industry.

Thanks for your continued support of the DIY speaker building community, Sir.

Awesome! Pretty cool to be picked by a major company to pimp their stuff. 🤘🏼

If you want a good treble response, the first thing you need to do with remove the convex half roll surround from the midwoofer. Because it just causes diffraction and thus affects the off axis response of the tweeter in a chaotic way. So even with a DSP based crossover and you throw biquads at it and make the tweeter perfectly flat on axis the polar response is not going to follow in a smooth predictable fashion. You can see this on virtually ALL of SB acoustics coaxials.

So that rules out the SB12PACR25-4-Coax as an advanced midrange coax. It's a standard midwooder coax. Can it sound good? Sure. But is it advancing the state of the art? Definitely not.

Now the TB on the other hand has flat(tish) surround, tweeter flush with the mid's cone, and mid's cone transition to the edge the tweeter continues at an angle to ensure smooth waveguide loading of the tweeter. So it has all the ingredients of a good coaxial midrange. These are the learnings from 5thelement as he created a coax with off the shelf parts:

http://5een.co.uk/SB17Coax.htm

TB's decision to NOT go with a completely flat surround allows them to have a bit more excursion and allows it to dig deeper than a pure midrange. So like the KEF LS50 UniQ, I'd say it's fair tradeoff. The flowery design detailing around the tweeter is an elaborate phase shield. Just like KEF's "Tangerine" thing UniQ- it dampens the ultrasonic resonance of the tweeter, but trades it for a wiggly treble response- about a 7dB window between 2K and 20K. Which might look/feel bad, But the HF unit from KEF's TOTL UniQ for its 2022 Blade/Reference Meta, well that also wanders within 7dB, so in comparison, it's not bad. KEF's tweeter, howver is a tad slightly smoother.

So hopefully TB have made a good one. What will be be clincher will be the harmonic distortion and directivity, which unfortunately TB do not show in their datasheets.

Now my question is, what's the price on one. And what's up with that rapidly rising impedance hill on the mid cone?

The 2" voice coil will have a higher inductance than some other drivers.

I can request HD and polars, we'll see if they have them handy. I bet they do.

InDIYana Event Website

The 6 1/2" TB co-axial is $245 at PETT, so I'd be surprised if this one was much less than $200. I consider this line of TB co-axials to be knock-offs of the KEF drivers - at one point TB released cabinet plans for the 6 1/2 that looked like a copy of the LS50 cabinet. I'm looking forward to what Ben designs as I think the 4 1/2" size is the sweet spot for co-axials.

Ben,

Kudos.

As a fan of (a few beyma) coaxials, and your crossover skills, I'm looking forward to what you end up with. Ongoing comments on your trials and resulting changes would be great.

Thank you! It was on a relay from someone else in the biz I've known for awhile. I was tagged to be a new acquaintance and familiar name, and then she said these would be sent to me. I was floored!

InDIYana Event Website

I’d like to see the normalised directivity. That depends on the cone size and geometry (curve profile). I doubt TB would have that.

Would love to see an independent data from @Wolf

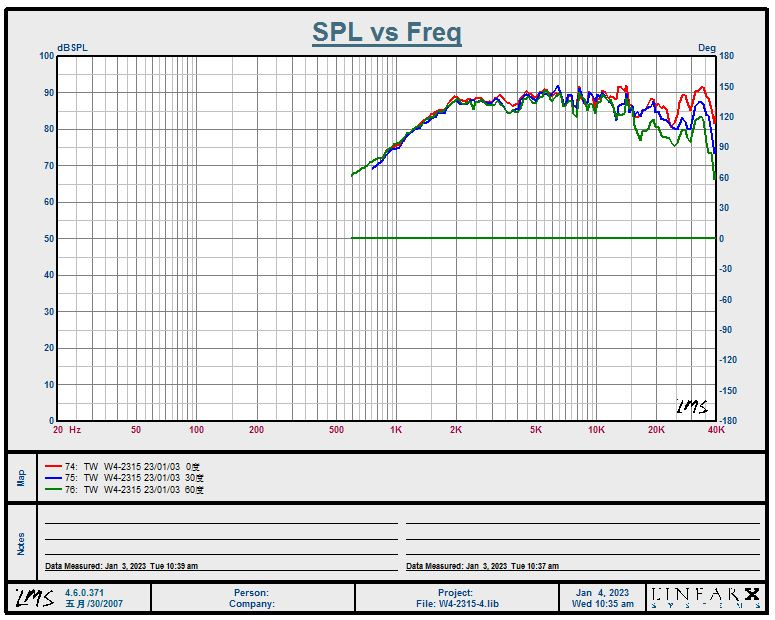

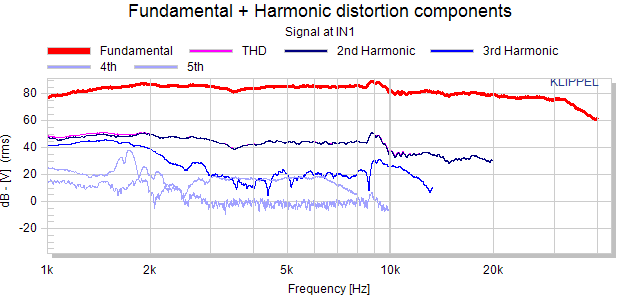

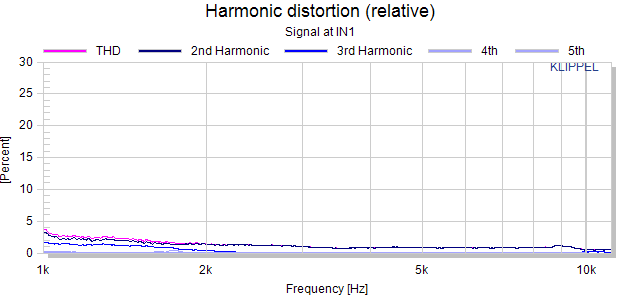

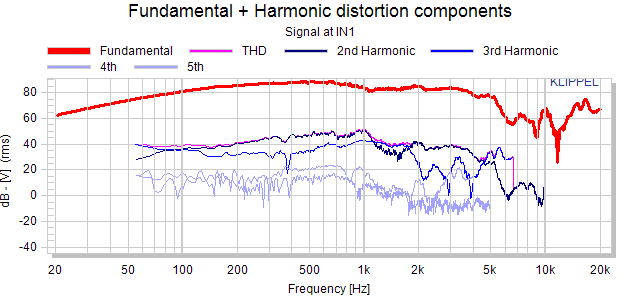

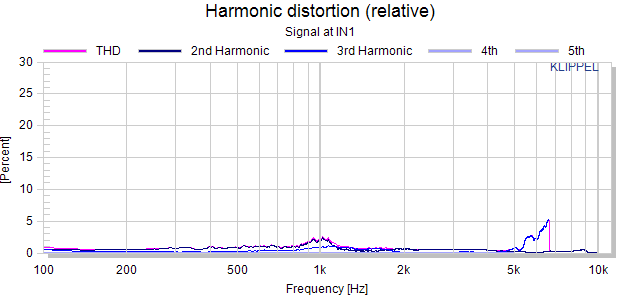

Tweeter:

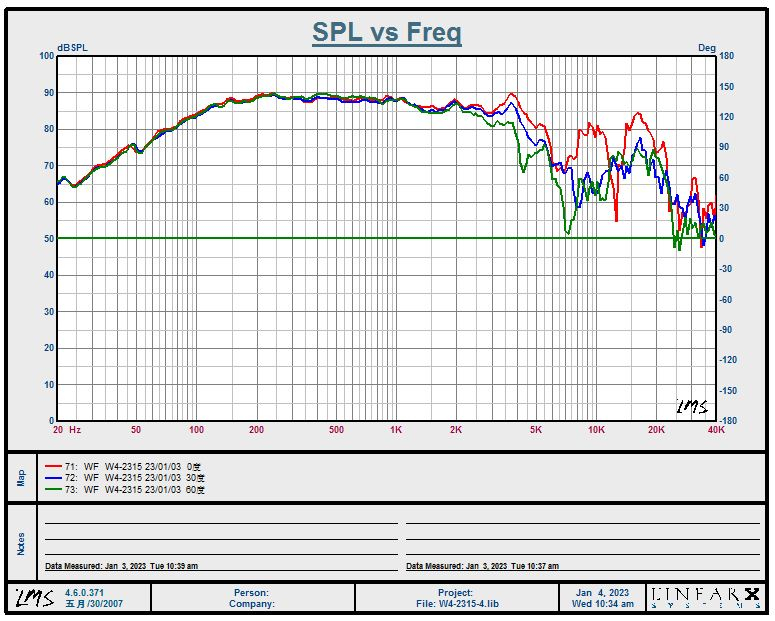

Midrange:

InDIYana Event Website

Looks very impressive and an XO at 3KHz . . . Compact 3-way for sure.

Looks to me like they cut it pretty close without alot of wiggle room.

By my untrained eye seems like they might want to cross a little higher?

Edited- Redundant

I guess I don't see anything different, but to each their own.

InDIYana Event Website

There’s nothing different, it’s pixel perfect resize.

And yes, in a previous life I was a college maths tutor. Axes is important. I just don’t see any no point having distortion at -20dB; or a Y scale at 100dB. (Lower than your noise floor).

I made a comment to Amir over at ASR about this erroneous comments on his nearfield graphs; but he stood his ground- he’s going to keep.

This is your thread Ben, and this is different. I haven’t added any commentary; I just resized them to make them easier to interpret. But I’m happy to remove these graphs of you feel there are superfluous/redundant.

As I said, I don't know why you did that, because I can still read these plots the same way I always do and did the other ones. Tweeter shows about -40dB, and woofer -30dB at the resonance.

InDIYana Event Website

Turns out I have the perfect chambers already in house. I scavenged some plastic Bunn O Matic filter funnels from the trash at a former place of employment, and the size is perfect.

Just for reference, it seems you can still purchase them on online singly for about $8.

https://www.google.com/search?q=bunn+o+matic+filter+funnel&ei=jtJWZJ3jBeLNptQPkce_iAo&oq=bunn+o+matic+filter+funnel&gs_lcp=ChNtb2JpbGUtZ3dzLXdpei1zZXJwEAMyBQghEKABOggIABCiBBCwAzoCCCk6BQgAEKIEOg4IKRCKBRCxAxCDARCRAjoLCCkQgwEQsQMQgAQ6BwgpEA0QgAQ6BggpEBYQHjoOCAAQjwEQ6gIQjAMQ5QI6EQgAEI8BEOoCEIwDEOUCEIsDOhcILhCPARDqAhCMAxDlAhCLAxCbAxCoAzoFCCkQoAE6CAgAEIoFEJECOg4ILhCKBRDHARDRAxCRAjoRCC4QgAQQsQMQgwEQxwEQ0QM6BQgAEIAEOgsIABCABBCxAxCDAToLCC4QigUQsQMQgwE6BAgpEEM6DgguEIoFEMcBEK8BEJECOgsILhCABBCxAxCDAToICAAQgAQQsQM6CwguEIAEEMcBEK8BOgsILhCvARDHARCABDoFCC4QgAQ6EAguEIoFELEDEMcBENEDEEM6CwguEIAEEMcBENEDOgYIABAWEB46CAgAEIoFEIYDOgUIIRCrAjoICCEQFhAeEB1KBAhBGAFQlQxY915gqmdoAXAAeASAAYEEiAGwK5IBDDguMjQuMS4xLjIuMZgBAKABAbABHsgBBbgBAsABAQ&sclient=mobile-gws-wiz-serp

Patent and drawing:

https://patents.google.com/patent/US3374897A/en

I won't really even need the front third of the chamber for fit and usage. We'll see what works...

InDIYana Event Website

InDIYana Event Website

Okay, since my barn is slowly coming down with help, and I was in need of some thick wood to make the baffle extend forward for facilitation of the Versa-boxes; I took a section of native white oak from a former floor joist. This wood was hewn from the ground where my current home sits, and the barn was erected in 1896. I grew up next door so this wood was a former inhabitant of this small group of acreage. I don't think the home is as old as the barn is. It means the wood and myself were both raised here, and has a bit of a stronger meaning to me.

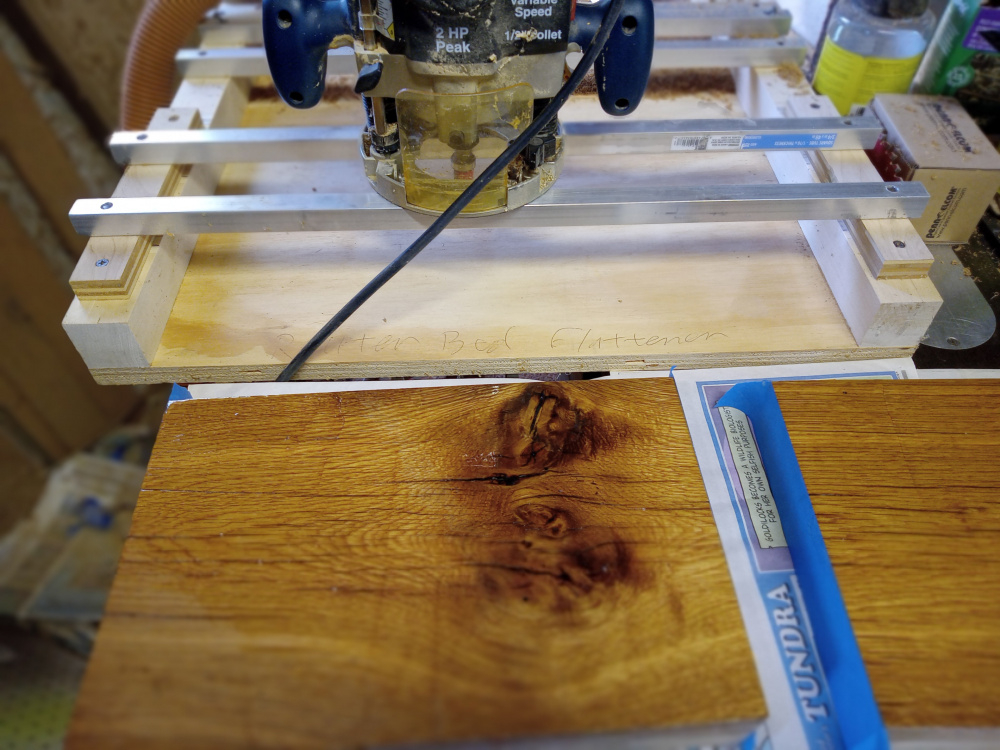

So, I squared up this section of wood into two pieces that would fit the baffle areas of the Versa-boxes you've seen with the Missing Links and Drottnar projects. Surprisingly, the boards were not cupped or bowed, and looked good. The dimensions are at this point 12 7/8" x 8.5", by roughly 1.75" thick. The inner 0.75" will be inset in the cabinets and not seen, and I wanted to be able to angle-chamfer away excess material on the baffle edges. I won't get but maybe a small round on the top front edge due to driver placement, but the side edges should be good this way. I used a wire brush and orbital sander to clean them up and take down the high spots. This also led me to see that one side looked better than the other, and the saw-kerfs were still visible and neat to see. I hope to be able to keep some of that look...

So, last weekend was Meniscus' cabinet sale. I texted Ken to see about maybe getting lunch the night prior. He asked if I had baffles that needed cut for drivers, and thought maybe Mark would let him use their CNC to cut the rebates and holes for me. So, I brought the baffles and drivers along for the ride. I did ask, and Mark let me post images of the process. Since they are not air-tight as they sit, he had to cut a recess for the baffles to nest in for the duration of the machining.

Thanks to Ken and Mark!

InDIYana Event Website

Being that the boards were sitting for a week prior the CNC, and had not shifted or bowed at all, I thought they were good to go. 3 days after the CNC, I went to do more work on them and found more work than expected would be needed. The boards had cupped forward around the rebates, about 3/16" worth total depth from extremes edges to center. To try and prevent further atrocities, I coated the backs in epoxy to make the wood stronger and fill the cracks for stopping air leaks too. Today, I used my router flattening bed to remove the curve, and then gave the backs another coat of epoxy for good measure. At the moment they sit drying.

The painters tape on the edges allows the epoxy fills to stay in the deep cracks without pouring out the edges/ends.

I am happy to say that the backs are pretty flat again, so that is one problem down. A good sand after the epoxy sets, and I'll be working the fronts. I hope to save some of the aged look, but may need to redo the faces and some of the rebates for flatness.

Stay tuned...

InDIYana Event Website

Actually, no. The baffles the Scandivifias used were of the siding, which is another species of wood. Pine? Same barn they are from though. At that point though, only a few boards had fallen off, and the barn still stood rather well.

Good memory, Nick, as that was 2007...

InDIYana Event Website

I'll have to look...

InDIYana Event Website

Trying to get these back to spec, I went and measured the rebates this morning. The vertical is still at dimension, but the horizontal has been decreased by 3/16", and the drivers won't fit in that dimension. I was forced to think about my options:

1- I could flatten the front of the baffles and partially lose the look and then reroute.

2- I could recut the rebates flat atop the bowed faces somehow to save the look.

I like option 2. I figured out if I raise the height of the still attached centers, which are relatively flat across their tops, I can recut the dimensions of the rebates. I looked at using a vertical shim down the middle of the face, but it's less than 1/8" height difference from edge to center and I'd have to make different ones for each board. Attaching a 1/8" thick mdf circle to each center to raise it higher seems the easiest approach. This should work for the coax and the woofer hole quite easily. However, since the baffle is still not flat, I will have to cut a mild rebate mostly at the horizontal extremes for the woofer because it was intended to be surface mounted.

I used an old compass to find my centers using the geometric arc method.

I will screw the mdf to the centers and route flush to the perimeter. Then I have to add more flushed screws to hold it in place during the reroute, remove the center screw and go. At least I can use the same mdf circles on both baffles.

Wish me luck...

InDIYana Event Website

InDIYana Event Website

I think the wood would have lots of character even without the marks. Older growth like that often has much tighter grain than the faster growing species used for commercial wood. Thus it usually looks much more unique than what we are used to seeing.