Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

PWR RYD's InDIYana 2024 theme project thread

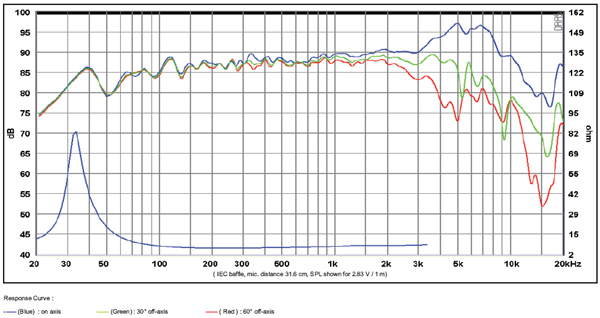

So I got started building my theme project for next Spring's InDIYana. I am using the SB17MFC35-8 poly cone woofer and yet to be determined tweeter. Maybe the Beast Mode, maybe the RS28A. Here is the woofer manufacturer's infinite baffle FR. Looks like a pretty easy driver to work with.

It will be a DCR design using 2" PVC ports. Modeled F3 is 34 Hz and it can take a full 20 Watts all the way down to 28 Hz with an output of 100+ dB.

I'm building it with the 3/4" thick particle board shelving from Menards. That's a lot of wood for <$20!

I'll probably make the rear panel removable so I can experiment with adding/removing damping material from the two chambers.

Comments

Scratch that... I need the rear panel glued on as the foundation of squareness for this project. Maybe just a small removable panel. We'll see.

Internal gross volume works out to be just barely under the rules criteria. 1.487 cuft

Made a little progress before it got too hot in the garage to work. Ports epoxied in and panels starting to get glued together:

Keep us posted on what you find regarding the tuning of those ports. A lot of 'opportunity' and some interesting interactions?

I've pretty much locked myself into this simulated design so to speak. With the ports epoxied in place and no removable rear panel it pretty much is what it is. I'm not too worried. I used the micka program Ben linked in his Anomolies project thread. I tested that piece of software with several of my pevious builds using Unibox and the results were identical so I have fairly strong confidence in that software's accuracy. I am able to mess around with the amount of damping material though.

A union would make it easy to add an inch, could move it around to measure the difference. With 4 internal port ends it would be easy to have a deviation greater than an inch. I also wonder how the ports will interact at higher volumes/displacement.

Made a little progress this past weekend.

Driver rebates turned out perfect!

This piece of 1" thick foam is all the lower chamber will get for damping.

ABC enclosure? I must have missed you saying that.

https://www.jfcomponents.com/

That is what WinISD calls it, yes. DCR or DBR is more common.

InDIYana Event Website

I didn't know WinISD could simulate DCR's. Grumpy has never advertised that feature, lol

I don't know how accurate it is at doing so, but yes, it can model ABC/DCR alignments.

I think I trust Jurgen Micka's sheet more than WinISD.

Whether Chris knows it or not...

InDIYana Event Website

And FWIW I was not bragging that "The driver rebates turned out perfect". More of a relief statement. That is my LEAST favorite part of building speakers!!! I hate the stress of that process but I feel that it is a necessary thing from a diffraction standpoint as well as visual. Otherwise I'd just hammer out some rough holes with my saber saw or hole saws and surface mount every single driver every single time

I hear you. It's especially nerve racking in a completed and finished cabinet.

That is why I invested in a lot of Freud carbide hole saws a year ago. Makes things go much faster....

InDIYana Event Website

Ditto! Nail biting the whole time.

...and MDF is SOOO much less stressful than a hardwood baffle. If I EVER do oak baffles again someone PLEASE take away my router.

I picked up a jasper jig knockoff to see how I like the concept. It comes with a 1/4" bit-centering plug but no pin. A 1/8" drill bit works as a pin except for the smaller diameters that are under the router plate. I'll probably just have to sacrifice one of the drill bits to make a short pin. I also picked up a simple drill bit guide so I can be reasonably sure the hole is plumb to the surface. Sofar it seems OK. But I pulled out my old jig to cut the smaller holes that I needed for now. Next on the list I think is a decent ruler to more accurately measure the depth of cut. Tape measure is far from ideal.

https://amazon.com/dp/B09NNCN1NT?ref=ppx_yo2ov_dt_b_product_details&th=1

https://amazon.com/dp/B00F1ZJFZK?psc=1&ref=ppx_yo2ov_dt_b_product_details

You can buy pins from McMaster-Carr.

You could also buy a piece of steel rod from Home Depot and with just a hacksaw and file make a bunch of pins.

https://www.homedepot.com/p/Everbilt-1-8-in-x-12-in-Cold-Rolled-Plain-Round-Rod-800397/204331423

I just use drill bits, pack of them from Hobo Freight.

Hazard Fraught?

I got one of these. Nice because it gives you a ton of those little ones that are always breaking every 3 seconds. I dropped it while it was opened one time and seems like I lost half of them somehow. I'm about to go buy another. They are cheap and I don't mind abusing em.

https://menards.com/main/tools/power-tool-accessories/drill-bits-accessories/tool-shop-reg-titanium-twist-drill-bit-set-160-piece/82770/p-1444448125712-c-10079.htm?tid=6597592590625799649&ipos=28

I may have been wrong there. It might be BassBox Pro that does ABC alignments. I am not ultra familiar with either program.

InDIYana Event Website

Just a quick update with no pictures... the baffles are now glued on. Now I just need to flush trim them and router the 3/4"roundovers. Then I can mount and wire the drivers and start taking my barage of measurements. If everything goes right there is a slim chance these might make it to Iowa with prototype external crossovers. We'll see!

I can't wait to get the drivers wired and mounted so I can see how close the woofer's measured impedance is to the modelled.

Here is the model: