@kenrhodes said:

Dayton PS95-8 and the TB W6-1139SIF

I'll start a new thread instead of mucking up Bill's thread... but those are in fact the drivers Bill is using. Mine are completely different drivers. Sorry Bill.

In addition to impedance and drivers, I'd like to see harmonic distortion plots down to 10Hz or so.

Your distortion plot looks very good. My guess is that you are probably using a larger wideband driver than I am. Would this distortion plot be for both your widebander and woofer(s) operating together. Or for just the widebander alone? My plots were for just the widebander.

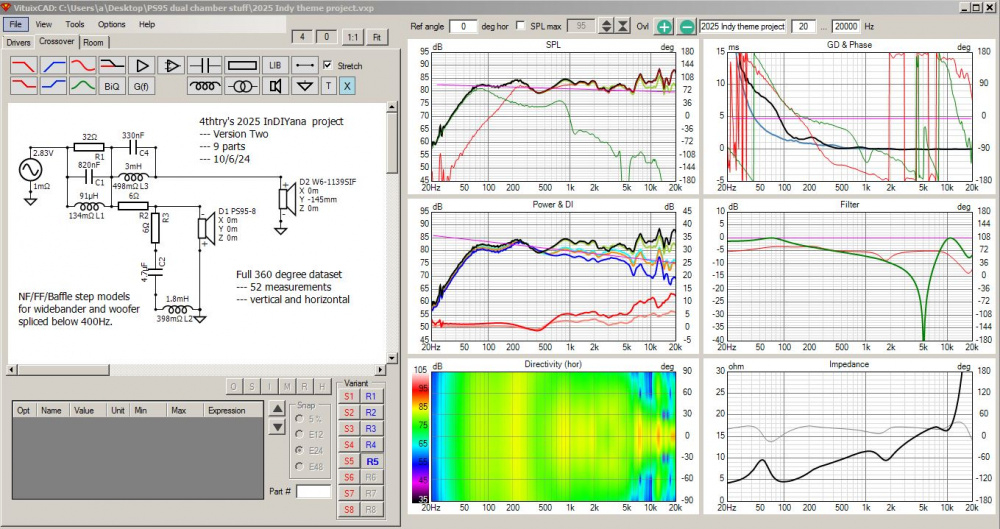

I dug through my junk box looking for xover parts and discovered that I had very few of the parts needed. So I revised several xover parts, using VituixCAD's optimizer, based on what I had on hand in my junk box. In the end, I was actually able to come up with a better preference score rating after making several substitutions. The only part I could not find was a 0.09mH inductor, which could not be adjusted higher or lower. But this value is easy to hand wind myself on a small bobbin with 18ga magnet wire. Then I'll finish it up with two small 1/8" masonite circuit boards and I should be good to go.

@4thtry said:

Your distortion plot looks very good. My guess is that you are probably using a larger wideband driver than I am. Would this distortion plot be for both your widebander and woofer(s) operating together. Or for just the widebander alone? My plots were for just the widebander.

The wideband driver is the Stereo Magazine 3.5" (built by SS). Basically the same driver as the Peerless TC9FD18-08. That distortion measurement is of the final project, both drivers playing with the filter in place, at 1 meter, ~ 85 dB.

Crossovers are all wired up and ready to be installed in the cabs. I ran a DATS V2 impedance curve on each one and get a perfect match to my VituixCAD modeled impedance curve. All of my solder joints are therefore probably good, with no connection points inadvertently skipped or misrouted.

The two small inductors are my DIY hand wound creations. One measures 0.093mH with a DCR of 0.196 ohms. The other measures 0.092mH with a DCR of 0.167 ohms. One of them is probably wound a bit tighter, resulting in a slightly lower DCR. I highly doubt that this will be audible, as it seems to make no difference at all in the modeled response.

During deep, loud bass percussive type music, the denim would actually blow out the top of the vents and change the impedance curve (and sound). So, I added pinstriping to the aperiodic vents using two long strips of red foam. They are held in place with double sided carpet tape. Works good. The denim now stays inside the vent.

I mounted the banana jacks on the back using a small piece of aluminum angle:

I wonder why the denim would blow out but not get sucked in. They should be equal but opposite forces. There must be a step or lip inside that tee fitting.

@PWRRYD said:

I wonder why the denim would blow out but not get sucked in. They should be equal but opposite forces. There must be a step or lip inside that tee fitting.

Nope. No lip. Perfectly smooth inside and out. The denim is free to move both in and out on bass transients. The inside of the Tee fitting, however, is lightly stuffed with denim, so the in/out motion is slightly asymmetrical. I have the denim pulled apart into very small batches because I needed to tease it out in order to very lightly stuff the line. As a result, the small amount of denim in the two 1/2" by 3/4" Tee openings is free to fly around independently of the denim in the line. So when I crank it up to about 90dB in the listening chair, the denim goes flying out the port and hits the floor.

I'm really liking the sound quality of this "low impedance" aperiodic design. Sounds much better than the sealed version. Much more relaxed and musical sounding, if that makes sense. My guess is that this has something to do with the magnitude of the impedance curves. Low impedance equals better sound, at least to my ears. I was not expecting this, so I don't think that this is some type of confirmation bias on my part. I'll bring my set of 4 aperiodic port plugs along to Iowa. Then, when we play them, I can quickly flip back and forth between sealed and aperiodic so that everyone in attendance can hear the difference (or not).

I made some covers to hide the pipes inside. Speakers should be rule compliant now. I think. The covers will be friction "press fit" into position using foam rubber inserts. Plan is to rattle can spray the covers flat black when the weather gets better. Still too cold and humid in my garage for painting right now (30 to 40F).

If you look closely, you will notice that the covers hang off the back edge by about 1 inch. This is an intentional and is intended to prevent internal pressure build up that could "de-tune" the two small "variovents" located on top of the internal coupling pipes. So, it is now a triple vented system of sorts.

Got up to a balmy 52F (11C) today in SE Wisconsin. So, two coats of flat black, sanded smooth with 220 grit, tacked, then two final coats of semi-gloss black enamel. This is the fast drying (15 minute) rattle can enamel (Rustoleum Professional in the 15oz silver cans), which seems to go on much better than the other smaller 12oz cans or the 12oz 2X Rustoleum cans. Cabs are now done and ready for Indy.

In prep for next month's Speaker Design Competition (SDC), I modified my xover to roll off the deep bass going to my PS95-8 wideband drivers. I glued four 55uF PP caps (paralleled up for a total of 220uF) onto a piece of plexiglass. Then I bolted the plexiglass to the top of the cabinets with 4 brass screws and wired the caps in series with the driver plus terminals. This should help to improve midrange and treble clarity somewhat on tracks with lots of energy in the 20 to 50Hz range.

I don't know if this mod technically makes them a 2 way, as opposed to a 1.5 way. Maybe they can be called a 1.75 way, since the lower xover frequency spans a wide band from about 100Hz up to about 500Hz or so.

Comments

Your distortion plot looks very good. My guess is that you are probably using a larger wideband driver than I am. Would this distortion plot be for both your widebander and woofer(s) operating together. Or for just the widebander alone? My plots were for just the widebander.

I dug through my junk box looking for xover parts and discovered that I had very few of the parts needed. So I revised several xover parts, using VituixCAD's optimizer, based on what I had on hand in my junk box. In the end, I was actually able to come up with a better preference score rating after making several substitutions. The only part I could not find was a 0.09mH inductor, which could not be adjusted higher or lower. But this value is easy to hand wind myself on a small bobbin with 18ga magnet wire. Then I'll finish it up with two small 1/8" masonite circuit boards and I should be good to go.

Junk box parts:

Revised 6 pack:

The wideband driver is the Stereo Magazine 3.5" (built by SS). Basically the same driver as the Peerless TC9FD18-08. That distortion measurement is of the final project, both drivers playing with the filter in place, at 1 meter, ~ 85 dB.

Crossovers are all wired up and ready to be installed in the cabs. I ran a DATS V2 impedance curve on each one and get a perfect match to my VituixCAD modeled impedance curve. All of my solder joints are therefore probably good, with no connection points inadvertently skipped or misrouted.

The two small inductors are my DIY hand wound creations. One measures 0.093mH with a DCR of 0.196 ohms. The other measures 0.092mH with a DCR of 0.167 ohms. One of them is probably wound a bit tighter, resulting in a slightly lower DCR. I highly doubt that this will be audible, as it seems to make no difference at all in the modeled response.

All done and ready for Iowa.

During deep, loud bass percussive type music, the denim would actually blow out the top of the vents and change the impedance curve (and sound). So, I added pinstriping to the aperiodic vents using two long strips of red foam. They are held in place with double sided carpet tape. Works good. The denim now stays inside the vent.

I mounted the banana jacks on the back using a small piece of aluminum angle:

I wonder why the denim would blow out but not get sucked in. They should be equal but opposite forces. There must be a step or lip inside that tee fitting.

Nope. No lip. Perfectly smooth inside and out. The denim is free to move both in and out on bass transients. The inside of the Tee fitting, however, is lightly stuffed with denim, so the in/out motion is slightly asymmetrical. I have the denim pulled apart into very small batches because I needed to tease it out in order to very lightly stuff the line. As a result, the small amount of denim in the two 1/2" by 3/4" Tee openings is free to fly around independently of the denim in the line. So when I crank it up to about 90dB in the listening chair, the denim goes flying out the port and hits the floor.

I'm really liking the sound quality of this "low impedance" aperiodic design. Sounds much better than the sealed version. Much more relaxed and musical sounding, if that makes sense. My guess is that this has something to do with the magnitude of the impedance curves. Low impedance equals better sound, at least to my ears. I was not expecting this, so I don't think that this is some type of confirmation bias on my part. I'll bring my set of 4 aperiodic port plugs along to Iowa. Then, when we play them, I can quickly flip back and forth between sealed and aperiodic so that everyone in attendance can hear the difference (or not).

I'm interested in hearing the differences.

I made some covers to hide the pipes inside. Speakers should be rule compliant now. I think. The covers will be friction "press fit" into position using foam rubber inserts. Plan is to rattle can spray the covers flat black when the weather gets better. Still too cold and humid in my garage for painting right now (30 to 40F).

If you look closely, you will notice that the covers hang off the back edge by about 1 inch. This is an intentional and is intended to prevent internal pressure build up that could "de-tune" the two small "variovents" located on top of the internal coupling pipes. So, it is now a triple vented system of sorts.

Got up to a balmy 52F (11C) today in SE Wisconsin. So, two coats of flat black, sanded smooth with 220 grit, tacked, then two final coats of semi-gloss black enamel. This is the fast drying (15 minute) rattle can enamel (Rustoleum Professional in the 15oz silver cans), which seems to go on much better than the other smaller 12oz cans or the 12oz 2X Rustoleum cans. Cabs are now done and ready for Indy.

In prep for next month's Speaker Design Competition (SDC), I modified my xover to roll off the deep bass going to my PS95-8 wideband drivers. I glued four 55uF PP caps (paralleled up for a total of 220uF) onto a piece of plexiglass. Then I bolted the plexiglass to the top of the cabinets with 4 brass screws and wired the caps in series with the driver plus terminals. This should help to improve midrange and treble clarity somewhat on tracks with lots of energy in the 20 to 50Hz range.

I don't know if this mod technically makes them a 2 way, as opposed to a 1.5 way. Maybe they can be called a 1.75 way, since the lower xover frequency spans a wide band from about 100Hz up to about 500Hz or so.

If you applied a high pass filter to the fullrange driver (the caps in series) then it is a 2 way regardless of how big the overlap is.