Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Pugmouth150 SB and RS

Way, way back when, one of my first design builds was a 14L TM with an RS150 and a Tangband 28-537 tweeter.

That build was posted on PETT here:

https://techtalk.parts-express.com/forum/speaker-project-gallery/48970-targas-rs150-and-tangband-28-537-tm

I ended up selling that to a good friend, who loved it, and we compared it many times to a much larger 3 way with an RS225 woofer.

So he gifted that pair to his son, and requested another one similar. So I noticed that I did not have a "killer" TM in that size, and that I had

a pair of SB15CAC30-8 mid-woofers on the shelf. I wanted to go a bit more upscale with the tweeter, so I bought 2 pairs of the SB Acoustics SB21RDCN-C000-4.

At minimum, I wanted to directly compare bass performance of the 2 woofers, and also suspect that the SB will be much clearer into the midrange than the RS150.

I saw someone's SB design on PETT, and wanted those cosmetics with a big ass flared port up front:

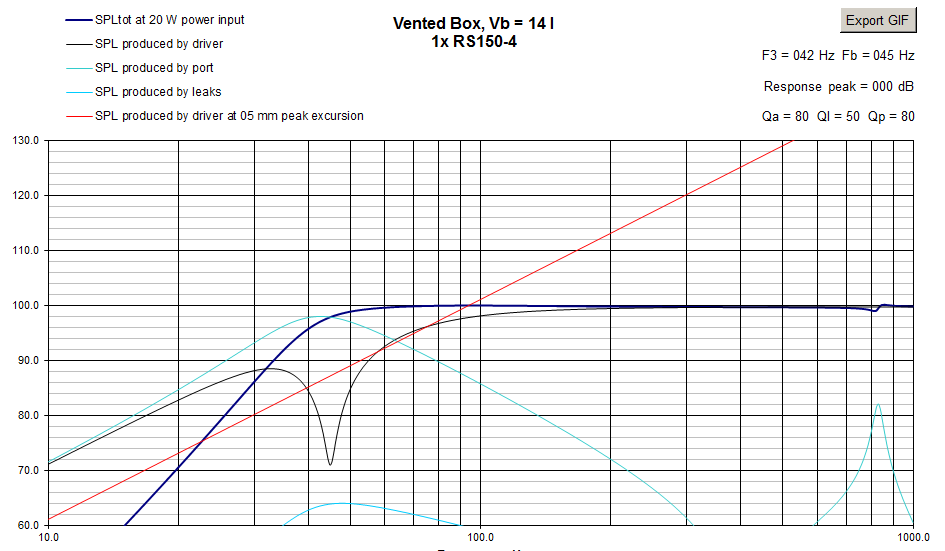

Somewhat surprising, the Unibox models for both woofers came out very,very similar:

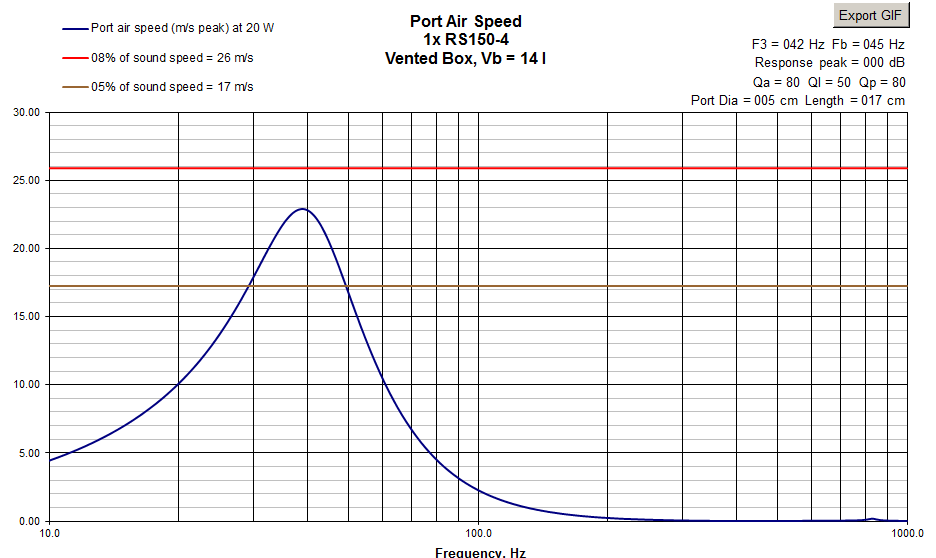

Port velocity is acceptable, considering it's modeled at more than the maximum the speaker will ever play:

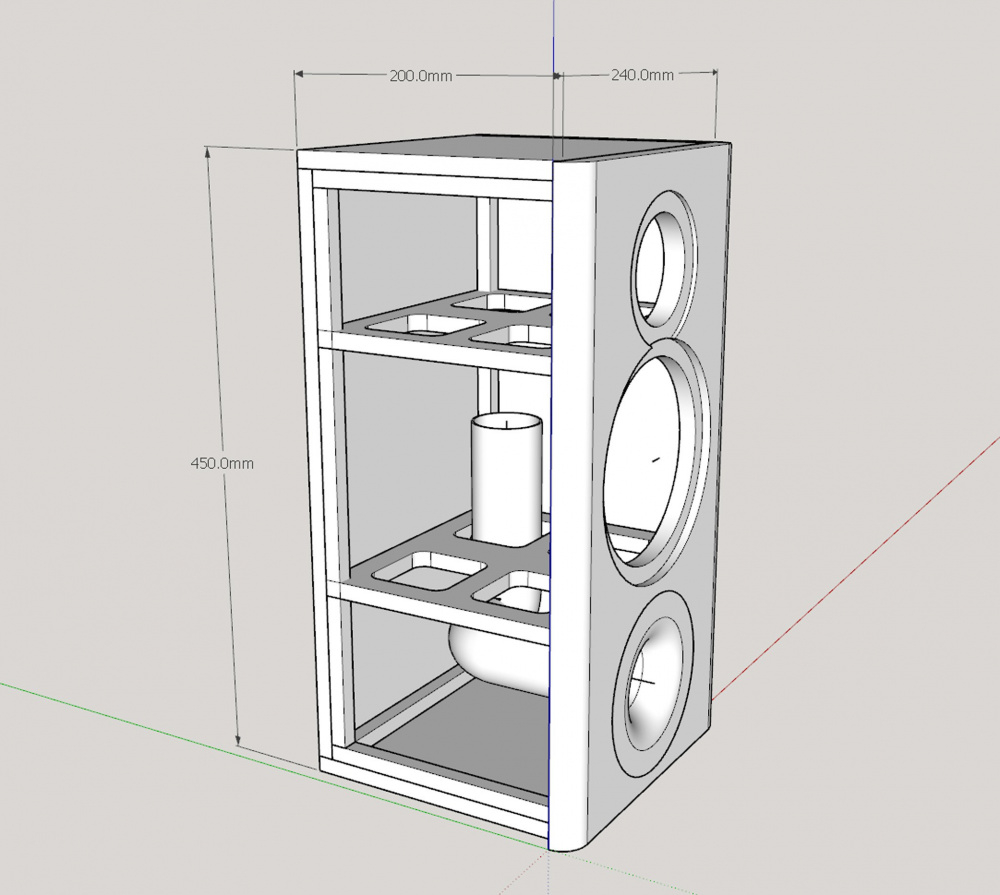

Boxes are 12 MM Baltic Birch with 2 window pane braces.

I decided to make his pair quarter cut cherry veneer with a 3/4" solid cherry baffle:

Finish is Tried and True Danish Oil, but I'll put some gloss poly on top after a while

My pair will be more upscale - Sapele 4/4 baffle, and Movingui veneered box.

Oil on the Sapele, and lacquer on the Mivingui to keep it as white as possible.:

More later!

don

Comments

Nice Wood!

Very nice! I think you'll like that woofer. I used the aluminum version in one design I took to Ankeny last month. I think the box is about the same size as yours. I wasn't overly impressed by the bass in that big conference room, but here at home, a foot or so out from the wall, it does pretty well.

Along the lines of "necessity is the mother" - I am not a wood artist like some, but I try my best.

The first sapele baffle routered out fine, but on the last router cut for the tweeter on the second baffle, suddenly I

realized that the router was "wandering" OMFG! By the time I shut it down, I was presented with this:

Well, I let that set for about 2 weeks while I tried not to obsess about it. Finally figured out that I could straighten the sides of the goof with some chisel work, and cut a thin plug to fill the gap. This is a test fit with DNA to check the grain match.

So it looked at this point like it might work.

A little more router circle work, and it came out almost perfect. Whew! Dodged the bullet.

Excellent save! That's as seamless as it gets. No one will be the wiser, unless they were nearby to hear the stream of curse words.

Nice blending work! I didn't even notice this repair on the first picture!!

Looks great, another way to hide the oops, would be to inlay a stripe down the center if a grain match isn't feasible.

Thanks guys!

The Deft rattle can lacquer I am using has darkened the movingui veneer a bit more than I might have liked, but it's really popping the wavy grain!

I love that woofer and I bet that tweeter will match up with it perfectly.

Gorgeous build! ...and I'll second the nice save on the tweeter route👍🏻

Sprayed 3 coats of Deft rattle can lacquer on the veneer, then scuff sanded with 320 and sprayed one more top coat. Finally got to put the baffle and box together for a money shot this morning. Looks better than I could have imagined. Very happy with the combination! In another couple of days, I will top coat the baffles with gloss wipe on poly, then glue them on.

Like I mentioned in the other thread, you guys make some killer looking stuff. Bet it sounds just as good.

I forgot to mention - several months ago I lamented that always when I routed the baffles to fit the veneered box, the bottom bearing created creases in the veneer that in some cases were really hard to sand out. Someone suggested a double bottom bearing bit. I got this Bosch 1/2 inch for $24 from Amazon. It cuts like butter, and zero, i repeat zero creases in the veneer. Now I'm a big fan!

Good to know. I'm putting one on my Christmas list. I had some minor lines on my last project from my current bit.

Dang, wish they had it with a 1/4" shank for my palm router.

Yonico has 1/4" spiral down cutting with a double bearing.

Thanks Nick. Found it on Amazon: https://amazon.com/Flush-Carbide-Spiral-Down-Cut-Router/dp/B00KZM0WMO/ref=psdc_686958011_t2_B018SZGL60

You're welcome Ed.