Well, I laid out a base coat of Duplicolor Metallic Chrome, more why later.... I waited a couple days, and went to fill in with spot filler, and the paint just gummed and fell off. $#!+!!! Then I spent the next 4 hours removing the silver. It looked good, but didn't cure for whatever the reason.

Today I laid about 2 light coats of gloss paint+primer white, and it looks good at the moment minus a couple runs to sort out in a few days after it dries.

I'm hopeful I can keep on the current path and get these done in a week or 2...

What product had you applied to the cabinets prior to the Duplicolor coating, Wolf?

(We ARE speaking about the cabinets and not the baffles at this point, correct?).

This is a cool little speaker, Wolf! Looks great, and I bet it will sound great. I've really gotten hooked on coaxial speakers. I still dig the horns, but I go to the coax for my serious listening. I hope that I get to hear these someday. Glenn.

@Steve_Lee said:

What product had you applied to the cabinets prior to the Duplicolor coating, Wolf?

(We ARE speaking about the cabinets and not the baffles at this point, correct?).

Epoxy, 2 coats, well sanded. It worked fine on the previous projects I have done so, Purveyor for one.

Yes, cabs only.

Along those lines, yep, best as I can do anyway. I'm no ugly woofer...

Having a go with gloss white as base second attempt. Should still be reflective enough. I'll keep ya posted...

It is really not as shiny as it looks in the photo, at least to me, and I did lighten the lighting in the photo just a smidge. I think it has to do with the lighting and the white paint and the radius of the exit. The paint is in fact, dry, in the photo and is 2 coats.

It may very well be a blessing in disguise!

I did a test of the paint process since the jungle order arrived today sans the final clearcoat cans. I have a plan how this will all flesh out in process and color, and am hopefully able to pull it off.

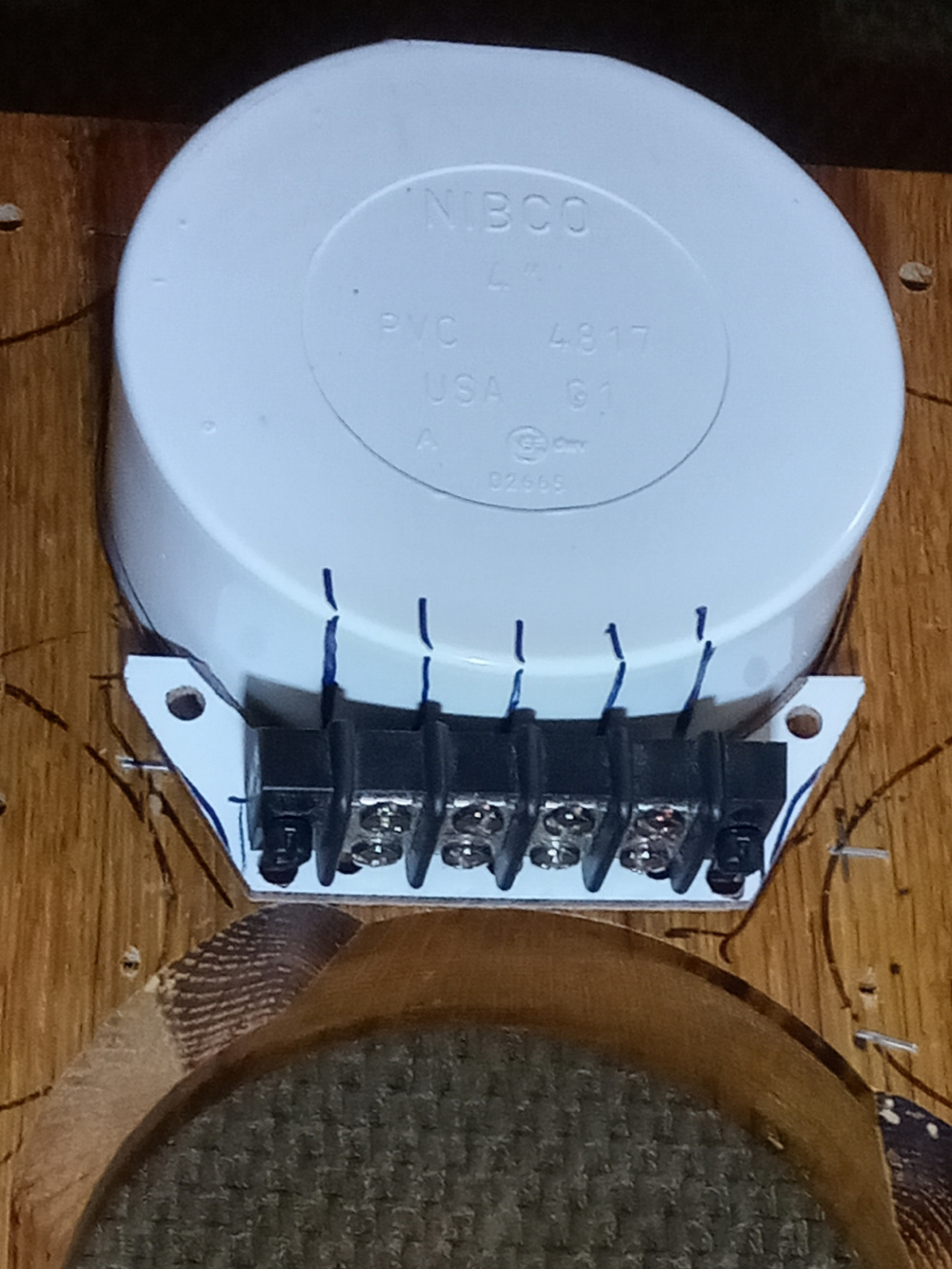

Made a little mounting plate for a set of terminals to wire up the coaxial today. It fits around the cup and in between the drivers for easy positioning. I will likely be boring a single hole for 4 conductor cable, or 4 small holes for each connection, as I have not made up my mind yet.

Then I proceeded to sand the previous white to remove imperfections and prep for more paint. I found that harbor freight sells sanding discs in 600 and 800 grit. Wow, that made a difference this time as I only typically go to 400 under most of the painting process. It felt really smooth after that. When I sanded with 500/1k prior, it was always by hand. This really helps the flat areas having the discs available. I sanded the round overs all by hand with 400 grit this time before applying 2 more coats of white gloss.

My paint order came in from the Jungle, and I did a test piece. I originally was going to follow up the white with VHT Anodized Red, VHT Nite Eyez Red clear, and then Nite Eyez Black clear. I was looking for the black-glass marble that had a red see through sheen. I also got a case (6 cans) of both clearcoat and the Ano, and 2 cans of Duplicolor Effex glitter clear. The test piece showed that the Effex wasn't going to be seen, that the red clear alone was too pink or burgundy, and that the black would likely negate the whole process to not being visible. I was going to go red anodized and red clear over the white and then clear and done.

Since I had the Effex, I did the initial clear coats with those over the white, and of course this hearkened back to the Scandivifias' finish. It yields a freshly fallen snow look, or maybe close to a pearlescent or metalflake white. Being I am starting to whittle the time away before the SDC, I decided to just go with it, and have 2 coats of Duplicolor 1k clear already applied. It's still not 'basic gloss white', and looks really nice. It will also go well with the old white oak baffles. In a couple days after this paint cures, I'll address the couple small runs I have, and the small amount of orange peel on the backs. Then it's a light sand and more clear to finish it off, and waiting a couple weeks for it to fully cure before reinstalling stuff.

My vintage hifi radar caused my eyes to be immediately drawn to what looks like a vintage integrated amp in the background. Realistic SA-1000?

Yeah, that was an old amp my uncle gave me some 25 yrs ago. Eventually, one channel quit working, and he said it was flaky when I got it. I used it most at my sister's grad party back in '99, and later as a passive-sub amp. It worked good that grad day, with the first pair of speakers i built. Since I upgraded, it has set for a good spell out there, and I did think about it when decibel posted his redo of his of the same model. I doubt I'll ever do more with it...

Did a prelim simulation with measured impedances, real applied box and tunings as they sit, and modified mfr curves. I wanted a ballpark to see before I get measurements done later this week.

Xover looks like 530/3.5k; 3 parts on each of the woofer and tweeter, and 9 on the midrange. That's really not bad for a 3way. I was able to get away with a 1st electrical highpass on the midrange and 2nd on both T/W, but needed 3rd order lowpass on the mid along with a breakup notch. As expected, sensitivity is about 80dB, and I get an F3 of about 40Hz. I modeled the off axis out to 60deg in PCD, and it does not vary much, though it looks like a very minor bunching at about 6kHz. I have half a thought to cascade the highpass to the tweeter and protect it further. It did not seem to hinder the simulation.

I've been working on the baffles for chambers, wiring, and driver fitment this week. I should be ready to mount them tomorrow, and then mount the assembled baffles into the boxes in prep for measurement and verification.

Comments

Dang, that's the first newspaper I've seen in years...

My folks still subscribe, and my daughter and i like occasionally reading the funnies, so I save some for garage use.

InDIYana Event Website

My Father used to get the paper and he always saved the funnies for my kids. They loved them.

Well, I laid out a base coat of Duplicolor Metallic Chrome, more why later.... I waited a couple days, and went to fill in with spot filler, and the paint just gummed and fell off. $#!+!!! Then I spent the next 4 hours removing the silver. It looked good, but didn't cure for whatever the reason.

Today I laid about 2 light coats of gloss paint+primer white, and it looks good at the moment minus a couple runs to sort out in a few days after it dries.

I'm hopeful I can keep on the current path and get these done in a week or 2...

InDIYana Event Website

What product had you applied to the cabinets prior to the Duplicolor coating, Wolf?

(We ARE speaking about the cabinets and not the baffles at this point, correct?).

This is a cool little speaker, Wolf! Looks great, and I bet it will sound great. I've really gotten hooked on coaxial speakers. I still dig the horns, but I go to the coax for my serious listening. I hope that I get to hear these someday. Glenn.

Epoxy, 2 coats, well sanded. It worked fine on the previous projects I have done so, Purveyor for one.

Yes, cabs only.

InDIYana Event Website

Before I had to sand it back off....

InDIYana Event Website

I'm guessing the chrome was to act as a reflective base for a translucent coat. Candy finish? Glenn.

Along those lines, yep, best as I can do anyway. I'm no ugly woofer...

Having a go with gloss white as base second attempt. Should still be reflective enough. I'll keep ya posted...

InDIYana Event Website

Currently...

InDIYana Event Website

Holy crap that finish is shiny...

You referring to the silver or the white?

InDIYana Event Website

The whitey one. Look a that sheen around the port! Is it still wet in the photo?

Paint failure maybe a blessing in disguise?

Actually, shiny is not what you want in a base coat.

It is really not as shiny as it looks in the photo, at least to me, and I did lighten the lighting in the photo just a smidge. I think it has to do with the lighting and the white paint and the radius of the exit. The paint is in fact, dry, in the photo and is 2 coats.

It may very well be a blessing in disguise!

I did a test of the paint process since the jungle order arrived today sans the final clearcoat cans. I have a plan how this will all flesh out in process and color, and am hopefully able to pull it off.

InDIYana Event Website

Made a little mounting plate for a set of terminals to wire up the coaxial today. It fits around the cup and in between the drivers for easy positioning. I will likely be boring a single hole for 4 conductor cable, or 4 small holes for each connection, as I have not made up my mind yet.

Then I proceeded to sand the previous white to remove imperfections and prep for more paint. I found that harbor freight sells sanding discs in 600 and 800 grit. Wow, that made a difference this time as I only typically go to 400 under most of the painting process. It felt really smooth after that. When I sanded with 500/1k prior, it was always by hand. This really helps the flat areas having the discs available. I sanded the round overs all by hand with 400 grit this time before applying 2 more coats of white gloss.

My paint order came in from the Jungle, and I did a test piece. I originally was going to follow up the white with VHT Anodized Red, VHT Nite Eyez Red clear, and then Nite Eyez Black clear. I was looking for the black-glass marble that had a red see through sheen. I also got a case (6 cans) of both clearcoat and the Ano, and 2 cans of Duplicolor Effex glitter clear. The test piece showed that the Effex wasn't going to be seen, that the red clear alone was too pink or burgundy, and that the black would likely negate the whole process to not being visible. I was going to go red anodized and red clear over the white and then clear and done.

Since I had the Effex, I did the initial clear coats with those over the white, and of course this hearkened back to the Scandivifias' finish. It yields a freshly fallen snow look, or maybe close to a pearlescent or metalflake white. Being I am starting to whittle the time away before the SDC, I decided to just go with it, and have 2 coats of Duplicolor 1k clear already applied. It's still not 'basic gloss white', and looks really nice. It will also go well with the old white oak baffles. In a couple days after this paint cures, I'll address the couple small runs I have, and the small amount of orange peel on the backs. Then it's a light sand and more clear to finish it off, and waiting a couple weeks for it to fully cure before reinstalling stuff.

As the cabs sit:

InDIYana Event Website

Nice dude!

Thanks to all of you!

InDIYana Event Website

Applied a coat of Duratex to the bottoms as I want that surface to be very durable. Since these cabs can be used for several more projects, it certainly can't hurt. I sanded the clear lightly yesterday, as there were some spots that did not cut it for me, and the sides had some unwanted texture lower. I felt it was too humid to paint, so this week they will get what will be hopefully the last coats of clear. Then I will wait at least a week before progressing further.

The black furniture bolts have arrived, and the adhesive backed Woolous felt.

https://www.amazon.com/Woolous-Adhesive-Heavy-Surface-Furniture/dp/B07CVMPPTQ/ref=mp_s_a_1_3?crid=110THIH7K2UCD&keywords=woolous+adhesive+felt&qid=1688224722&sprefix=woolous+adhesive+felt,aps,110&sr=8-3&th=1&psc=1

This is about a 0.25" thick 40" roll, and I'm using it (among others) in the midrange chambers, as well as the slots in the stepped baffles.

InDIYana Event Website

Those are looking really nice, Wolf!

My vintage hifi radar caused my eyes to be immediately drawn to what looks like a vintage integrated amp in the background. Realistic SA-1000?

Got them recoated with clear today...

InDIYana Event Website

Yeah, that was an old amp my uncle gave me some 25 yrs ago. Eventually, one channel quit working, and he said it was flaky when I got it. I used it most at my sister's grad party back in '99, and later as a passive-sub amp. It worked good that grad day, with the first pair of speakers i built. Since I upgraded, it has set for a good spell out there, and I did think about it when decibel posted his redo of his of the same model. I doubt I'll ever do more with it...

InDIYana Event Website

Clean it up and recap it to start. Don't let it just sit.

It’s a fun amp, recap is easy work, I think I spent $50 or so in parts to do mine. I’ve got a scan of the schematic too if you want.

Looks like there might be an interested party wanting to take it off my hands...

InDIYana Event Website

Did a prelim simulation with measured impedances, real applied box and tunings as they sit, and modified mfr curves. I wanted a ballpark to see before I get measurements done later this week.

Xover looks like 530/3.5k; 3 parts on each of the woofer and tweeter, and 9 on the midrange. That's really not bad for a 3way. I was able to get away with a 1st electrical highpass on the midrange and 2nd on both T/W, but needed 3rd order lowpass on the mid along with a breakup notch. As expected, sensitivity is about 80dB, and I get an F3 of about 40Hz. I modeled the off axis out to 60deg in PCD, and it does not vary much, though it looks like a very minor bunching at about 6kHz. I have half a thought to cascade the highpass to the tweeter and protect it further. It did not seem to hinder the simulation.

I've been working on the baffles for chambers, wiring, and driver fitment this week. I should be ready to mount them tomorrow, and then mount the assembled baffles into the boxes in prep for measurement and verification.

InDIYana Event Website

InDIYana Event Website

Baffles look great! Look forward to seeing them in action.