Hey Ron, hope you don't mind me posting here as your thread is simply titled "3D printing" so figured I wouldn't start another one.

I got an Ender 5 Pro in December 2021 and finally finished setting it up 2 weekends before Iowa. My first print...the test-model cat that my kids took out to the garage and painted gold the next morning before I was up.

Second print, a 4" waveguide from Augerpro's project for the SB21SDC. I thought I had taken some pictures during the build, but I can't find any other than the completed baffle. Black PLA filament, sanded, filler primer, sanded, Krylon Fusion Black Textured paint, sanded, Krylon Fusion Flat Clear.

As I measure and examine the results I'll start a new thread, but for the moment I'm playing with a phase shield kind of faceplate for the Tymphany TC7FD 5cm cone full range, to see if the radiation pattern of the top octave can be improved.

A test print fresh from the printer:

Another design, one I think might perform better by guessing alone:

I'm doing more adventures in mixed media. I 3D printed some big roundovers for this set of Piccolos. I printed them with 1.6mm walls and then filled them with plaster (the photo is of the back side):

They're half-coated in a light application of fiberglass resin to mask the layer lines and the interface between the print & the MDF. Just waiting for next week's promised warm snap to spray 2nd primer & on to top coat.

@JasonP said:

As I measure and examine the results I'll start a new thread, but for the moment I'm playing with a phase shield kind of faceplate for the Tymphany TC7FD 5cm cone full range, to see if the radiation pattern of the top octave can be improved.

A test print fresh from the printer:

Another design, one I think might perform better by guessing alone:

Pretty sure Dirk and JP are in their mid to upper 40s like me. Cell (brick) phones hit in 88, and PCs like Tandys just a few years prior that. Cell phones as we know them now hit around 2000 or so. I don't think that most of the group here equates to the later millennial generation you speak of, but more likely GenX.

I was long in the workforce before the IBM 5150 came out which is where the technology began it's take-off IMO/E.

Everything about them had to be learned outside of formal education in spare time & after tax expense. I did not mean to create a negative conversation with my posted comment. We just see things differently as I am 64 and you are not.

You old codgers still able to learn new skills/tech at your advanced age amaze me along with the rest of those interesting/creative humans younger than all of us.

Fair enough. I wasn't trying to start an argument, just happened to notice an inconsistency with your comments was all. No offense was intended.

Ben (who is happily not able to be called a millenial.)

I was in 2nd grade before we got a black and white TV. I built my first computer from a kit before Apple existed. I did get an 2 year degree in Electronics Technology but never worked in the field. (graduated in 1970 at age 19 and was draft eligible during a recession) I taught myself to program, several different CAD programs, 3D printing and speaker design etc...

I have always had problems with first layers with print beds. The printer came with a flexible magnetic sheet that worked ok for a while but after use started leaving ghosts of old prints. I tried a glass bed and it did the same thing and the textured surface got damaged by the print head. I put a sheet of Buildtak on the glass bed and it was really good at getting the first layer to stick but big prints were almost impossible to remove.

I just ran across Garolite G10 which is the stuff they make printed circuit boards with. I've did a few prints with PLA and it's like magic. First layers stick to the bed when heated and when the bed cools it self releases. I literally just picked the part up off the bed of this piece I printed. The face facing the bed has a surface like glass and no sign of curling.

@Ron_E said:

I have always had problems with first layers with print beds. The printer came with a flexible magnetic sheet that worked ok for a while but after use started leaving ghosts of old prints. ...

Highly recommended.

Ron

Thank you for this!

I just washed my magnetic sheet 15 minutes ago, it has ghost remnants and I have literally only printed about 10 things. I was standing at my 3D printer as the bed warmed up as I read your post!

I've had some success with sanding (fine grit) and intense cleaning with isopropyl alcohol on the flexible plates, but they don't last forever that is for sure. I'll usually replace them every 3-4 kg of pla

= Howard Stark: "This is the key to the future. I'm limited by the technology of my time, but one day you'll figure this out."

My brother and I both use a mirror for the print bed. Get it CLEAN and it holds prints very well, releases when it's cool. It is also a nice way to look back up at the print head when needed.

Where I work we use plate glass and spray it with hair spray. I have never found the hair spray to be needed if the bed is level.

Both my brother and I have Creality printers with EZabl bed leveling. It makes printing almost idiot proof.

So having the bright idea to swap out the 0.4mm nozzle for a nice micro swiss steel 0.6mm nozzle, I proceed to do the procedure - heating up the end properly, using a socket to free the nozzle and as I removed it I could feel it suddenly fight me. Well then it came out broken, and it ruinined the threads on the heater block on the way out. Can't put a new nozzle in at all (note the angle of the nozzle):

Yeah, so I just took the time to install an all metal micro swiss hotend for it (Creality Ender 2 V2 Neo) and back to printing, just another expense on a substandard part from the manufacturer. But at the price of these Ender 3 right now, I can't say I'm surprised.

= Howard Stark: "This is the key to the future. I'm limited by the technology of my time, but one day you'll figure this out."

Comments

+10 !!!!

They're finally finished.

Ron

Those look great!

Yup, pretty nifty👍🏼

I like them, they remind me of children's building blocks being so colorful.

The "Legos"? Oh wait, those stinkin Danes would sue you! Or Parts Express would rip off your speaker project name AGAIN!

The dark blue is really nice. Good job on the prints.

That's my favorite color and since they were finished last, they have the best vinyl wrap job. I'm going to bring them to Ankeny.

Ron

It really is handy to be able to print your own ports. This is just a test print. I need to figure out how to place holes in Fusion 360 again.

Ron

I found a Black Friday deal (half off) on a CR Touch auto leveling kit and I will never buy a printer without auto leveling.

I just ran across this best 3D printer review on Tom's Hardware if anyone is shopping for a printer.

https://tomshardware.com/best-picks/best-3d-printers

Ron

What are some of the printer software favs?

Hey Ron, hope you don't mind me posting here as your thread is simply titled "3D printing" so figured I wouldn't start another one.

I got an Ender 5 Pro in December 2021 and finally finished setting it up 2 weekends before Iowa. My first print...the test-model cat that my kids took out to the garage and painted gold the next morning before I was up.

Second print, a 4" waveguide from Augerpro's project for the SB21SDC. I thought I had taken some pictures during the build, but I can't find any other than the completed baffle. Black PLA filament, sanded, filler primer, sanded, Krylon Fusion Black Textured paint, sanded, Krylon Fusion Flat Clear.

And lastly, some custom crossover boards...

Nice finish on the waveguide. Are the resistors above the plastic? I'd be worried about the heat and melting.

Ron

As I measure and examine the results I'll start a new thread, but for the moment I'm playing with a phase shield kind of faceplate for the Tymphany TC7FD 5cm cone full range, to see if the radiation pattern of the top octave can be improved.

A test print fresh from the printer:

Another design, one I think might perform better by guessing alone:

And the video of cura slicing that one with tree supports: https://youtu.be/B_yZ0JdZF9k

This is so cool and I believe there is a lot of potential here.

I'm doing more adventures in mixed media. I 3D printed some big roundovers for this set of Piccolos. I printed them with 1.6mm walls and then filled them with plaster (the photo is of the back side):

They're half-coated in a light application of fiberglass resin to mask the layer lines and the interface between the print & the MDF. Just waiting for next week's promised warm snap to spray 2nd primer & on to top coat.

My mind has been going in that direction with the 10" coaxes as well. I'm really interested in your investigation.

Sehlin Sound Solutions

Jealous. Cool stuff, guys!

Kids today having grown-up with cell phones and computers since birth totally amaze me.

Keep going!!

Pretty sure Dirk and JP are in their mid to upper 40s like me. Cell (brick) phones hit in 88, and PCs like Tandys just a few years prior that. Cell phones as we know them now hit around 2000 or so. I don't think that most of the group here equates to the later millennial generation you speak of, but more likely GenX.

InDIYana Event Website

I was long in the workforce before the IBM 5150 came out which is where the technology began it's take-off IMO/E.

Everything about them had to be learned outside of formal education in spare time & after tax expense. I did not mean to create a negative conversation with my posted comment. We just see things differently as I am 64 and you are not.

You old codgers still able to learn new skills/tech at your advanced age amaze me along with the rest of those interesting/creative humans younger than all of us.

Fair enough. I wasn't trying to start an argument, just happened to notice an inconsistency with your comments was all. No offense was intended.

Ben (who is happily not able to be called a millenial.)

InDIYana Event Website

I was in 2nd grade before we got a black and white TV. I built my first computer from a kit before Apple existed. I did get an 2 year degree in Electronics Technology but never worked in the field. (graduated in 1970 at age 19 and was draft eligible during a recession) I taught myself to program, several different CAD programs, 3D printing and speaker design etc...

Came to cell phones late.

Ron

I have always had problems with first layers with print beds. The printer came with a flexible magnetic sheet that worked ok for a while but after use started leaving ghosts of old prints. I tried a glass bed and it did the same thing and the textured surface got damaged by the print head. I put a sheet of Buildtak on the glass bed and it was really good at getting the first layer to stick but big prints were almost impossible to remove.

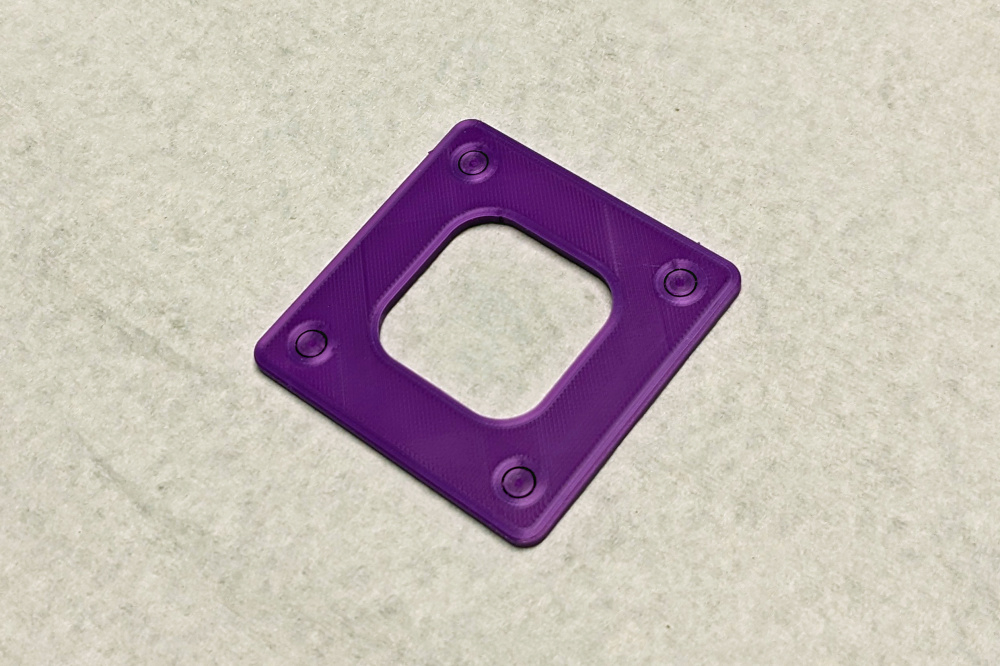

I just ran across Garolite G10 which is the stuff they make printed circuit boards with. I've did a few prints with PLA and it's like magic. First layers stick to the bed when heated and when the bed cools it self releases. I literally just picked the part up off the bed of this piece I printed. The face facing the bed has a surface like glass and no sign of curling.

The part is 2 3/4" square.

https://wilbursfinest.com/blog/f/everything-you-need-to-know-about-g10

Highly recommended.

Ron

Thank you for this!

I just washed my magnetic sheet 15 minutes ago, it has ghost remnants and I have literally only printed about 10 things. I was standing at my 3D printer as the bed warmed up as I read your post!

I've had some success with sanding (fine grit) and intense cleaning with isopropyl alcohol on the flexible plates, but they don't last forever that is for sure. I'll usually replace them every 3-4 kg of pla

My brother and I both use a mirror for the print bed. Get it CLEAN and it holds prints very well, releases when it's cool. It is also a nice way to look back up at the print head when needed.

Where I work we use plate glass and spray it with hair spray. I have never found the hair spray to be needed if the bed is level.

Both my brother and I have Creality printers with EZabl bed leveling. It makes printing almost idiot proof.

I have purchased sheets of G10 from McMaster-Carr.

So having the bright idea to swap out the 0.4mm nozzle for a nice micro swiss steel 0.6mm nozzle, I proceed to do the procedure - heating up the end properly, using a socket to free the nozzle and as I removed it I could feel it suddenly fight me. Well then it came out broken, and it ruinined the threads on the heater block on the way out. Can't put a new nozzle in at all (note the angle of the nozzle):

Yeah, so I just took the time to install an all metal micro swiss hotend for it (Creality Ender 2 V2 Neo) and back to printing, just another expense on a substandard part from the manufacturer. But at the price of these Ender 3 right now, I can't say I'm surprised.

Is it possible to run a tap in and clean up the damaged threads?