The Milescraft one looks good. I'm aware of the other designs, but I like the idea of repeatability - if I know I need a 3 7/8 hole for a driver, I want to set the jig for that and start cutting. That Milescraft is looking better - you can leave the base on your router, and just swap the large circle and small circle scales as needed. The small circle is calibrated in inches and metric, so I can spot always converting mm to inches....

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

Wow - if you can't figure out how to build that one without their $5.00 plans, I'm not sure you should be using a router.

I noticed the Milescraft base has metric and imperial scales. That would be helpful. I'm lookin at you Jasper Jig! Why have we in the US not adopted the metric system for woodworking? It's so much easier.

I used to use a circle jig made of 1/4" masonite before buying a Jasper jig. I am equally disillusioned with the Jasper jig and may look into the Milescraft option. Price is right, and I like the SAE/Metric options. I need to research if it will fit on my primary router.

@Tom_S said:

I noticed the Milescraft base has metric and imperial scales.

That's the biggest selling point for me, as well as being able to dial in exactly the right size you want. 100% of the drivers I use conform to metric sizes for the frames.

@jr@mac said:

I used to use a circle jig made of 1/4" masonite before buying a Jasper jig.

Same! Had a lot of holes in it - sneaking up on the right diameter.

Yep!

When I realized the jasper jig was essentially the same thing, I bought the JJ. My home made "drill test" had slightly more accurate results with the effect that I was generating a lot of waste in my trial and error approach.

I never bought a jig. I made a cheesy one out if masonite to do the larger woofer diameters.... but I just use my digital calipers and drill a pivot hole right in my plunge router's base for most drivers under 7". My router base looks like Swiss cheese, but I can usually find an existing hole thats perfect. Anyone who has seen my speakers in person would never say my driver rebates "need a little improvement". I do make test cuts in scrap wood before plunging into a nice piece of hardwood.

A friend of mine 3D printed a router jig for me. I've lost track of where the file went but there are many examples on Thingverse. https://thingiverse.com/

I use a digital calipers and a 1/4" dowel pin to set the diameter.

Side note: I just bought a couple of MDF handi-panels from Menards to prototype my latest design.... Day-um! Was gonna use particle board to save some $ but it was actually more expensive than MDF 🤨

@Ron_E said:

A friend of mine 3D printed a router jig for me. I've lost track of where the file went but there are many examples on Thingverse. https://thingiverse.com/

I use a digital calipers and a 1/4" dowel pin to set the diameter.

I see that this can cut a circle down to 1.625" diameter. I've been using a Black & Decker circle cutting guide for past 30 years or so, but it can only go down to 2.625" dia. minimum using a 1/4" bit. And I have had several situations were I needed to go smaller. I bet you could re-design this slightly to go down to as low as 1" in diameter using a 1/4" bit.

@4thtry said:

I see that this can cut a circle down to 1.625" diameter. I've been using a Black & Decker circle cutting guide for past 30 years or so, but it can only go down to 2.625" dia. minimum using a 1/4" bit. And I have had several situations were I needed to go smaller. I bet you could re-design this slightly to go down to as low as 1" in diameter using a 1/4" bit.

I could definitely get it a little tighter, but I'd minimizing some structures that I want in place and also precluding use of a 1/2" bit, which is very handy for cutting recesses. Also, holes smaller than 1.625" are very easy to cut with a hole saw or forstner bit, so I thought it was a good compromise. With that said, the model would be very easy to modify for a smaller minimum hole size if desired.

I recently got involved in a Facebook discussion about what appeared to be a Jasper jig. It turned out it was a clone that didn't come with any of the alignment tools that Jasper supplies. While I was researching jigs I discovered that Jasper has a metric version which is something I had long wished that they had. I ordered one immediately.

It looks to me that that the hole-to-hole increment is 2mm in diameter with a 6mm bit. To get the advertised 1 mm increment you need to switch to a 6.5 mm bit which adds 1mm diameter. Just like the English version is limited to 1/16" increments with out changing bits.

@Ed_Perkins said:

It looks to me that that the hole-to-hole increment is 2mm in diameter with a 6mm bit. To get the advertised 1 mm increment you need to switch to a 6.5 mm bit which adds 1mm diameter. Just like the English version is limited to 1/16" increments with out changing bits.

You're correct about 2mm increments. It uses a 1/4" dowel pin for alignment which means it's designed for a 1/4" bit. The pins for the diameter setting holes are 1/8" too.

I'm having trouble finding a 6.5mm router bit. I may send the good folks at Jasper a message and see if they have any insight.

Worst case scenario, some of my rebates end up 1mm oversized, which is actually pretty positive for swelling induced by painting/duratexing so the outlook is not bleak not too mention manufacturing tolerances of the driver baskets. If I make the move to veneering, however, I will want that more precise fit.

I read the instructions and while the alignment pins are US they call for a 6mm bit. Putting a bit with a 6mm shank in a 1/4" collet is not safe according to Google. There are 6mm 1/4" shank bits available but I don't see anything with a spiral.

I use 1/4" bits to make templates. I use the templates with top bearing bits to make the rebates. If the template fits the driver I can be sure the driver fits the rebate before I mess up the cabinet. I keep the templates in case I need to make another rebate that's the same size in the future.

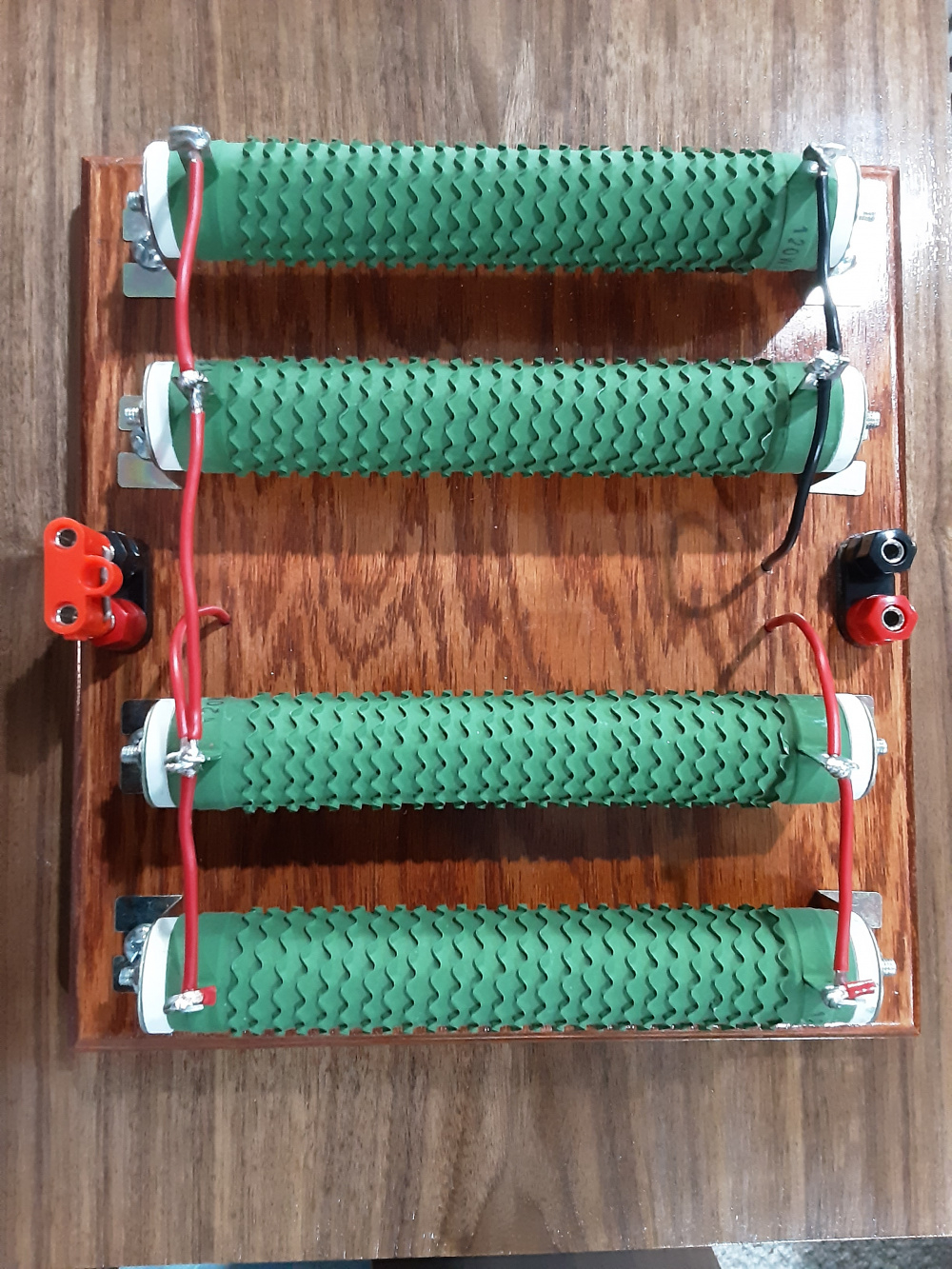

I threw this dummy load together this weekend, I've had the resistors laying around for a while. It's good for 240 watts into 8 ohms and 480 watts into 4 or 16 ohms.

Comments

The Milescraft one looks good. I'm aware of the other designs, but I like the idea of repeatability - if I know I need a 3 7/8 hole for a driver, I want to set the jig for that and start cutting. That Milescraft is looking better - you can leave the base on your router, and just swap the large circle and small circle scales as needed. The small circle is calibrated in inches and metric, so I can spot always converting mm to inches....

I ended up making my own out of 1/2 inch plexiglass

Wow - if you can't figure out how to build that one without their $5.00 plans, I'm not sure you should be using a router.

I noticed the Milescraft base has metric and imperial scales. That would be helpful. I'm lookin at you Jasper Jig! Why have we in the US not adopted the metric system for woodworking? It's so much easier.

I used to use a circle jig made of 1/4" masonite before buying a Jasper jig. I am equally disillusioned with the Jasper jig and may look into the Milescraft option. Price is right, and I like the SAE/Metric options. I need to research if it will fit on my primary router.

That's the biggest selling point for me, as well as being able to dial in exactly the right size you want. 100% of the drivers I use conform to metric sizes for the frames.

Same! Had a lot of holes in it - sneaking up on the right diameter.

Yep!

When I realized the jasper jig was essentially the same thing, I bought the JJ. My home made "drill test" had slightly more accurate results with the effect that I was generating a lot of waste in my trial and error approach.

I never bought a jig. I made a cheesy one out if masonite to do the larger woofer diameters.... but I just use my digital calipers and drill a pivot hole right in my plunge router's base for most drivers under 7". My router base looks like Swiss cheese, but I can usually find an existing hole thats perfect. Anyone who has seen my speakers in person would never say my driver rebates "need a little improvement". I do make test cuts in scrap wood before plunging into a nice piece of hardwood.

A friend of mine 3D printed a router jig for me. I've lost track of where the file went but there are many examples on Thingverse. https://thingiverse.com/

I use a digital calipers and a 1/4" dowel pin to set the diameter.

Ron

Side note: I just bought a couple of MDF handi-panels from Menards to prototype my latest design.... Day-um! Was gonna use particle board to save some $ but it was actually more expensive than MDF 🤨

Homodepot and Lowes were even higher ☹

This looks like the one I designed and posted on the CSS blog: https://www.css-audio.com/single-post/2017/08/29/diy-3d-printed-circle-jig-router-guide

That's the one.

I see that this can cut a circle down to 1.625" diameter. I've been using a Black & Decker circle cutting guide for past 30 years or so, but it can only go down to 2.625" dia. minimum using a 1/4" bit. And I have had several situations were I needed to go smaller. I bet you could re-design this slightly to go down to as low as 1" in diameter using a 1/4" bit.

That's why I designed mine to go to the side of the bit. You can get a little closer.

InDIYana Event Website

I could definitely get it a little tighter, but I'd minimizing some structures that I want in place and also precluding use of a 1/2" bit, which is very handy for cutting recesses. Also, holes smaller than 1.625" are very easy to cut with a hole saw or forstner bit, so I thought it was a good compromise. With that said, the model would be very easy to modify for a smaller minimum hole size if desired.

I recently got involved in a Facebook discussion about what appeared to be a Jasper jig. It turned out it was a clone that didn't come with any of the alignment tools that Jasper supplies. While I was researching jigs I discovered that Jasper has a metric version which is something I had long wished that they had. I ordered one immediately.

https://amazon.com/JASPER-Cutting-Perfect-Circles-Routers/dp/B09B175D1V

Ron

That's nice to see. You'd think the metric version would be available on Amazon Canada but...

It looks to me that that the hole-to-hole increment is 2mm in diameter with a 6mm bit. To get the advertised 1 mm increment you need to switch to a 6.5 mm bit which adds 1mm diameter. Just like the English version is limited to 1/16" increments with out changing bits.

I just ordered the metric Jasper. If I find time and weather permitting I'll cut a hole in some scrap and check it out.

You're correct about 2mm increments. It uses a 1/4" dowel pin for alignment which means it's designed for a 1/4" bit. The pins for the diameter setting holes are 1/8" too.

Ron

I'm having trouble finding a 6.5mm router bit. I may send the good folks at Jasper a message and see if they have any insight.

Worst case scenario, some of my rebates end up 1mm oversized, which is actually pretty positive for swelling induced by painting/duratexing so the outlook is not bleak not too mention manufacturing tolerances of the driver baskets. If I make the move to veneering, however, I will want that more precise fit.

You may be able to use English bits: 15/64" is 5.95 mm and 1/4" is 6.35 mm.

I read the instructions and while the alignment pins are US they call for a 6mm bit. Putting a bit with a 6mm shank in a 1/4" collet is not safe according to Google. There are 6mm 1/4" shank bits available but I don't see anything with a spiral.

Ron

I found 6mm and 5.5mm spiral bits with 1/4" shanks. If 6.5mm adds a mm to the circle size I assume 5.5 mm will subtract a mm.

https://woodline.com/products/solid-carbide-spiral-bits

https://mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/eagle_solid_carbide_spiral_bits.html

Ron

I think Jasper Tools may be missing another revenue stream by not selling the Metric bits too.

I have had bad luck with spiral bits.

I have as well in the 1/4" shank variety. More often than not, I use straight bits for my rebates.

InDIYana Event Website

I like to use a 1/4" shank 1/2" straight bit for doing driver recesses. I've also had bad luck trying to use a 1/4" shank 1/4" spiral upcut bit.

I use 1/4" bits to make templates. I use the templates with top bearing bits to make the rebates. If the template fits the driver I can be sure the driver fits the rebate before I mess up the cabinet. I keep the templates in case I need to make another rebate that's the same size in the future.

Ron

I threw this dummy load together this weekend, I've had the resistors laying around for a while. It's good for 240 watts into 8 ohms and 480 watts into 4 or 16 ohms.