Well, I have verified that I have some SpeakOns, so that may be how I go. I also plan on making some SpeakOn male plug to 4 female banana jack adapters while I am at it. I have that bag of jacks, so this will be simple to assemble.

Did some quasi-IB measurements of the TW045 ceramidomes while I was doing the Hancocks' precursory sweeps. I don't think these are quite as sensitive as 95dB, but more like 92dB, as they matched the AMTs' outputs. While testing the first sample's HD initially, the HD levels kept climbing. I'm not certain why that was as voltage was constant. I retested it after stopping the sweep, and they proceeded to regress back down closer to what they were initially. The second sample reflected that of the first, so it must be okay. I did use the 27uF cap on these as well, as blowing a $250 tweeter should not be an objective. The mic was at about a meter distance.

The bump of the resonance still rears up below 1kHz, as shown in the rolloff. I do not think they are as low HD as shown in VC, but I will redo these for better applied information when I get them mounted in the completed cabinets. The rolloff shows that 1.5-1.8kHz is likely a good place to xover these units, but HD suggests 1.2kHz is not an awful place to be either. Majority level is at -55dB from the fundamental. There are a couple 2nd order spikes in sample 2 between 3k and 4k, but they are not present on the other unit. I don't know if they are real at this point or not, as they could be a side-effect of how I did the measurements.

EDIT: The peaks in the FR around 4kHz may be an artifact of how these were measured. When mounted in the actual cabs this will get verified. Cap size also likely contributes to the rolloff, and these may be able to play to 1.2kHz.

Made some insulated 4-pole pigtails for use whenever with solder style metal Neutrik SpeakOns, and some Carol #10/4. Used some binding posts that didn't have jam nuts, soldered to the posts, swapped bands to orange and green for the extra of the 4x color coded leads, sheathed in red and black shrink with window to wire jacket color, and shrunk clear over the post nuts. I had to make sure accidental shorting didn't occur.

It should now be easier to prototype with outboard SpeakOns or connect to SpeakOn inputs with internal xovers. Pretty happy with how they turned out....

You've never done that in the case of blow-through? The Poplar let go, simple as that. To clean it up, you make it look even and same as the other. It really isn't that big of a deal.

I have a thought to bag/tape the drivers and fill with epoxy. I've done that before.

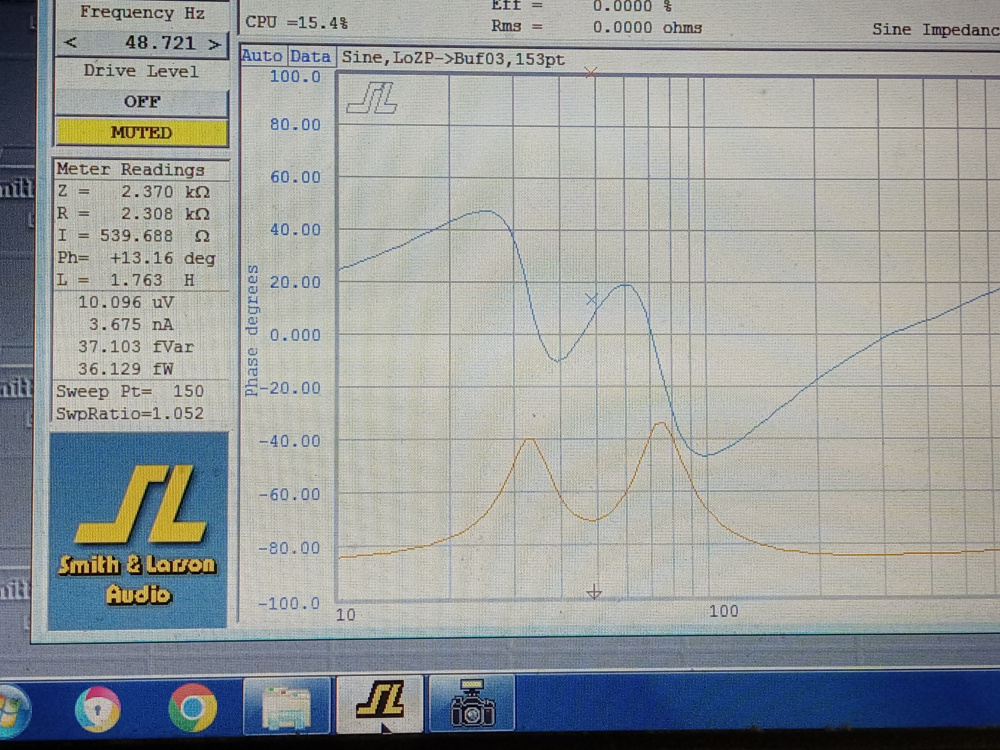

1st chamber only, DSA135PR pair loaded with 30g each. I placed space filler in the volume to mimic the driver magnet and ran the woofer inverted with the tweeter hole walled off to get a quick measurement. Being that there will be more inserted into the volume when completed, I feel 2Hz is negligible. Target was 50Hz, result is just below there at 48Hz.

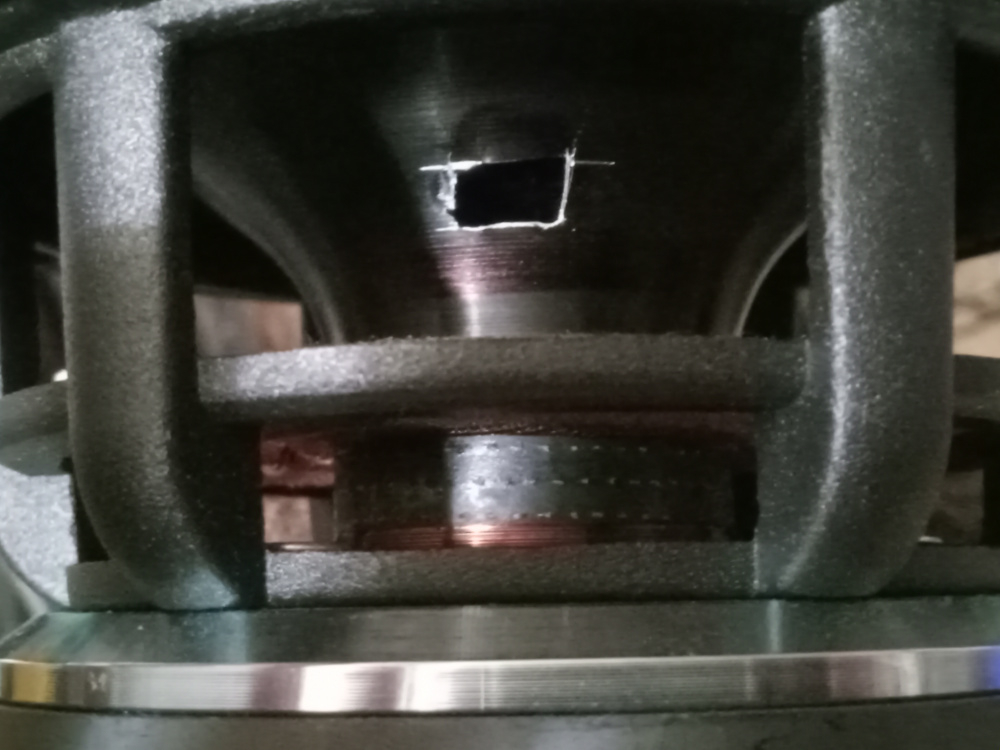

Ran it filter free with some bass for a few minutes. Good news is the PRs can take it. Bad news is, the woofer indeed sounds fuzzy due to no under cap venting. It's a noise maker under operation. I don't even need to test it for HD to know this.

Looks like I will be trying to vent the former...

@Wolf said:

You've never done that in the case of blow-through? The Poplar let go, simple as that. To clean it up, you make it look even and same as the other. It really isn't that big of a deal.

>

No never. If it did that baffle would be in my burn pile and new one made. No biggy. It's your project not mine. Proceed as you wish.

I think I've done this 4 times now. Scandivifias, Tesseracts, Canvas, and these.

Back to build progress, the 4x square holes are now cut in the rear of the cone. I used an exacto blade to scratch a grooved square, and then lifted it out from one side. Tape for cleanup, and done!

@Wolf said:

Made some insulated 4-pole pigtails for use whenever with solder style metal Neutrik SpeakOns, and some Carol #10/4. Used some binding posts that didn't have jam nuts, soldered to the posts, swapped bands to orange and green for the extra of the 4x color coded leads, sheathed in red and black shrink with window to wire jacket color, and shrunk clear over the post nuts. I had to make sure accidental shorting didn't occur.

It should now be easier to prototype with outboard SpeakOns or connect to SpeakOn inputs with internal xovers. Pretty happy with how they turned out....

Nice! Those should be good for a few thousand watts!

According to the person that informed me of how to ventilate these, his are still a bit of a noisy machine. I ran mine in a suboptimal arrangement last night after the family went to bed. I ran it free-air running sine-sweeps/tones from the Bluetooth on my phone by a signal generator app.

In this setup, below about 20Hz they are silent. No noise at all, and they were moving more than xmax.

Once I take it north of there, there is some air-movement noise. I know it is air, as the parts all move free without rubbing. The high pitch rushing is apparently gone. Again, this is all free air situ.

The informant said it is possible that the holes may need to be larger or more plentiful, but more plentiful leads to different integrity issues. My cuts are a bit smaller than his, so it is possible. However, it sounds like it is a noisier driver than some others. I'll have to see how it operates inside the cab.

More later...

Got a warm day today, almost 60 degrees. More progress...

I cut the 3/8" Lexan-Polycarbonate to fit the rear panels. I then cut the 8" PR through hole, bored for mounts, pilot holes, and through holes. When using plastic sheet like this, usually you have to screw into a material behind it if using a wood type screw. Through holes for these types should allow the whole screw to slide through the plastic. This is because the plastic will crack. The ways around this are to tap threads into the plastic and use a machine screw, or use a self-tapping type screw.

I'm not certain which way I'm going for all of the 8PR mounts, as a few have no material behind the plastic. Might end up a bolt and nut arrangement for 3 out of 5 mounts.

Then I bored for the side panel threaded insert mounts. I'm using 1/4-20 flush-head bolts and inserts. A total of 22 of them per cabinet have now been installed. They use an M6 Allen head, of which I don't have a 1/4" driver for, so all were done by hand. Let me state clearly that heartwood Poplar is a very hard material, and it was strenuous to get the inserts installed in those pieces by hand. I'm certain I will physically regret doing this tomorrow. (Not shown)

I will be boring the holes in the side panels for the through and flush next, but pilots are all done and present.

I have used a LOT of lexan over the years it is excellent stuff. Drilling and tapping would be a very clean look and should hold very well. Lexan will also hold a wood screw well as long as you pre drill the hole. Be cautious to not leave the holes too tight, I have broken screws in lexan. Lexan shouldn't crack like acrylic but you can get webbing if you stress it.

This is a fun build, I look forward to seeing it in person.

Did some web spelunking, and if this woofer is deemed too noisy and unremediable, I have a backup plan with the SB 12CAC-4. Specs are favorable, with more sensitivity, and will fit with maybe not too much trouble. It is about the only other 4" that can do the job.

@Wolf said:

Did some web spelunking, and if this woofer is deemed too noisy and unremediable, I have a backup plan with the SB 12CAC-4. Specs are favorable, with more sensitivity, and will fit with maybe not too much trouble. It is about the only other 4" that can do the job.

Made the cutouts a little larger, closer to what the informant had, and the noise is greatly reduced. Closest I can say is they resemble the area of 2 dimes, one per hole.

Honestly, I don't think I've ever seen one that wasn't vented in some way shape or form. There are several options; porous dustcap, fixed phase plug, ventilated former, vented base of cone, vented pole piece, core periphery venting, vented collar in the triple joint, segmented or subdivided magnet structures like Ellipticor/Hexadym/Audiom/AirCirc, etc.

Typically only cheap drivers don't have vented poles or formers, but usually at least one of the two is present. I'm absolutely dumbfounded why this driver would not at least have a vented former or pole. With its xmax capabilities, it absolutely should.

Well, I did fill out a form on their website to submit my concerns. It says they return queries in 72 hrs, but I heard nothing.

As to the project...

I have progressed quite a bit on the Lexan-Polycarbonate and this is how it looks currently. No wiring has been done as yet, and this was just for looks. I have figured out I'm using binding posts underneath the majority of the structure, and they will exit the rear, just underneath the rear bottom edge. No speakons this time.

I did have a couple errors. One is a drill bit broke on me while boring pilot holes for the rear right angle Lexan junction. I just bored another really close to it, and used the flat screw recess to mask the hole. On another of the same kind of hole, I had the drill bit grab and made the counterbore too deep. I'll need to fill a little epoxy in there and redo the through hole and finish the flat recess like the others to fix that one up.

I've also decided to use magic eraser melamine foam in the secondary chamber along with some Woolous felt lining. I was able to find some house brand erasers at Walmart that were larger than average and would suit the dimensions required.

Another problem to sort out in the near future, is the 8PR actually presses flat against the inside rear of the first chamber. This means I have to get creative with regards to the added mass, the new chamber under the 8PR spider, and the depth allowed for xmax under operation. I have a stash of round 23 gram steel slugs that suit these PRs very well. I bore the centers, paint them, and install. This will take 3 slugs each, and will readily smack the inside box as it sits. I'll first try forstnering or boring a hole and gluing a flat across the inside to compensate. I may have to either bore holes through the PR frame underneath the spider, or route/cut some slots or notches where the rear of the frame meets to keep the air flow from making noise.

I haven't sealed or filled or finished the wood yet. I had to make the parts all fit first. There will be a lot of gasketing to seal the Lexan to the poplar.

It is really hard to bore in the edge of the material in this case, but I needed to. I had no way to facilitate this with the press. The thing I learned with this Lexan material is to back it out more often whilst drilling, and don't stop until the bit is out of the pilot hole. I think the plastic melted and then resolidified, locking the bit in place. If this isn't what happened, the bit was just cheap or old. The chuck spun on it, and then it just snapped when I locked it back down. I am going to try and fill around the bit with epoxy, dripping it in the hole, but I'm not expecting miracles.

When I use flush head bolts or screws with plastic materials, I like to recess them so they don't stick out above the surface. I have a bit for such a task, and it works really well.

And I was just thinking in retrospect, I could have just cut holes in the plastic side panels for 2x more DSA135-PRs, and the design likely would have been fine. I'm hoping the 8PR cancels the motion of the active driver at least a little, while the side PRs balance their own forces quite readily.

Oh well, another trip around the barn backwards to find the door for me, only to find the door was locked. At least it looks good and will work.

Comments

What I like about the supposed X backing is that the PR will be protected. The SpeakOn method has merit though.

InDIYana Event Website

I’m sold. Must be that satisfying snap / lock.

Well, I have verified that I have some SpeakOns, so that may be how I go. I also plan on making some SpeakOn male plug to 4 female banana jack adapters while I am at it. I have that bag of jacks, so this will be simple to assemble.

Did some quasi-IB measurements of the TW045 ceramidomes while I was doing the Hancocks' precursory sweeps. I don't think these are quite as sensitive as 95dB, but more like 92dB, as they matched the AMTs' outputs. While testing the first sample's HD initially, the HD levels kept climbing. I'm not certain why that was as voltage was constant. I retested it after stopping the sweep, and they proceeded to regress back down closer to what they were initially. The second sample reflected that of the first, so it must be okay. I did use the 27uF cap on these as well, as blowing a $250 tweeter should not be an objective. The mic was at about a meter distance.

The bump of the resonance still rears up below 1kHz, as shown in the rolloff. I do not think they are as low HD as shown in VC, but I will redo these for better applied information when I get them mounted in the completed cabinets. The rolloff shows that 1.5-1.8kHz is likely a good place to xover these units, but HD suggests 1.2kHz is not an awful place to be either. Majority level is at -55dB from the fundamental. There are a couple 2nd order spikes in sample 2 between 3k and 4k, but they are not present on the other unit. I don't know if they are real at this point or not, as they could be a side-effect of how I did the measurements.

EDIT: The peaks in the FR around 4kHz may be an artifact of how these were measured. When mounted in the actual cabs this will get verified. Cap size also likely contributes to the rolloff, and these may be able to play to 1.2kHz.

InDIYana Event Website

Made some insulated 4-pole pigtails for use whenever with solder style metal Neutrik SpeakOns, and some Carol #10/4. Used some binding posts that didn't have jam nuts, soldered to the posts, swapped bands to orange and green for the extra of the 4x color coded leads, sheathed in red and black shrink with window to wire jacket color, and shrunk clear over the post nuts. I had to make sure accidental shorting didn't occur.

It should now be easier to prototype with outboard SpeakOns or connect to SpeakOn inputs with internal xovers. Pretty happy with how they turned out....

InDIYana Event Website

Those look really cool! I just use Wago lever nuts coming off my 4 pole SpeakONs and Carol cable.

What happened to the baffles between the drivers? I presume you are going to machine new baffles.

You've never done that in the case of blow-through? The Poplar let go, simple as that. To clean it up, you make it look even and same as the other. It really isn't that big of a deal.

I have a thought to bag/tape the drivers and fill with epoxy. I've done that before.

InDIYana Event Website

1st chamber only, DSA135PR pair loaded with 30g each. I placed space filler in the volume to mimic the driver magnet and ran the woofer inverted with the tweeter hole walled off to get a quick measurement. Being that there will be more inserted into the volume when completed, I feel 2Hz is negligible. Target was 50Hz, result is just below there at 48Hz.

InDIYana Event Website

Ran it filter free with some bass for a few minutes. Good news is the PRs can take it. Bad news is, the woofer indeed sounds fuzzy due to no under cap venting. It's a noise maker under operation. I don't even need to test it for HD to know this.

Looks like I will be trying to vent the former...

InDIYana Event Website

>

No never. If it did that baffle would be in my burn pile and new one made. No biggy. It's your project not mine. Proceed as you wish.

I think I've done this 4 times now. Scandivifias, Tesseracts, Canvas, and these.

Back to build progress, the 4x square holes are now cut in the rear of the cone. I used an exacto blade to scratch a grooved square, and then lifted it out from one side. Tape for cleanup, and done!

InDIYana Event Website

Well? How do they sound now?

Haven't had the chance to do that yet.

I'll update when I get to that, this evening or tomorrow...

InDIYana Event Website

Nice! Those should be good for a few thousand watts!

According to the person that informed me of how to ventilate these, his are still a bit of a noisy machine. I ran mine in a suboptimal arrangement last night after the family went to bed. I ran it free-air running sine-sweeps/tones from the Bluetooth on my phone by a signal generator app.

In this setup, below about 20Hz they are silent. No noise at all, and they were moving more than xmax.

Once I take it north of there, there is some air-movement noise. I know it is air, as the parts all move free without rubbing. The high pitch rushing is apparently gone. Again, this is all free air situ.

The informant said it is possible that the holes may need to be larger or more plentiful, but more plentiful leads to different integrity issues. My cuts are a bit smaller than his, so it is possible. However, it sounds like it is a noisier driver than some others. I'll have to see how it operates inside the cab.

More later...

InDIYana Event Website

Got a warm day today, almost 60 degrees. More progress...

I cut the 3/8" Lexan-Polycarbonate to fit the rear panels. I then cut the 8" PR through hole, bored for mounts, pilot holes, and through holes. When using plastic sheet like this, usually you have to screw into a material behind it if using a wood type screw. Through holes for these types should allow the whole screw to slide through the plastic. This is because the plastic will crack. The ways around this are to tap threads into the plastic and use a machine screw, or use a self-tapping type screw.

I'm not certain which way I'm going for all of the 8PR mounts, as a few have no material behind the plastic. Might end up a bolt and nut arrangement for 3 out of 5 mounts.

Then I bored for the side panel threaded insert mounts. I'm using 1/4-20 flush-head bolts and inserts. A total of 22 of them per cabinet have now been installed. They use an M6 Allen head, of which I don't have a 1/4" driver for, so all were done by hand. Let me state clearly that heartwood Poplar is a very hard material, and it was strenuous to get the inserts installed in those pieces by hand. I'm certain I will physically regret doing this tomorrow. (Not shown)

I will be boring the holes in the side panels for the through and flush next, but pilots are all done and present.

InDIYana Event Website

This is a fun build, like the use of acrylic.

I have used a LOT of lexan over the years it is excellent stuff. Drilling and tapping would be a very clean look and should hold very well. Lexan will also hold a wood screw well as long as you pre drill the hole. Be cautious to not leave the holes too tight, I have broken screws in lexan. Lexan shouldn't crack like acrylic but you can get webbing if you stress it.

This is a fun build, I look forward to seeing it in person.

Neato!!

Did some web spelunking, and if this woofer is deemed too noisy and unremediable, I have a backup plan with the SB 12CAC-4. Specs are favorable, with more sensitivity, and will fit with maybe not too much trouble. It is about the only other 4" that can do the job.

InDIYana Event Website

They are on sale right now too.

Made the cutouts a little larger, closer to what the informant had, and the noise is greatly reduced. Closest I can say is they resemble the area of 2 dimes, one per hole.

InDIYana Event Website

Hopefully you can resolve this issue.

In your experience have you had many other drivers with similar issues (lack of venting)?

Honestly, I don't think I've ever seen one that wasn't vented in some way shape or form. There are several options; porous dustcap, fixed phase plug, ventilated former, vented base of cone, vented pole piece, core periphery venting, vented collar in the triple joint, segmented or subdivided magnet structures like Ellipticor/Hexadym/Audiom/AirCirc, etc.

Typically only cheap drivers don't have vented poles or formers, but usually at least one of the two is present. I'm absolutely dumbfounded why this driver would not at least have a vented former or pole. With its xmax capabilities, it absolutely should.

InDIYana Event Website

Agreed. Hence I am not pleased with this unit.

Have you considered feeding this back to manufacturer as part of continued R&D and product improvement?

I know we shouldn't have to do it as end consumer, but there must be a way to close the loop.

Well, I did fill out a form on their website to submit my concerns. It says they return queries in 72 hrs, but I heard nothing.

As to the project...

I have progressed quite a bit on the Lexan-Polycarbonate and this is how it looks currently. No wiring has been done as yet, and this was just for looks. I have figured out I'm using binding posts underneath the majority of the structure, and they will exit the rear, just underneath the rear bottom edge. No speakons this time.

I did have a couple errors. One is a drill bit broke on me while boring pilot holes for the rear right angle Lexan junction. I just bored another really close to it, and used the flat screw recess to mask the hole. On another of the same kind of hole, I had the drill bit grab and made the counterbore too deep. I'll need to fill a little epoxy in there and redo the through hole and finish the flat recess like the others to fix that one up.

I've also decided to use magic eraser melamine foam in the secondary chamber along with some Woolous felt lining. I was able to find some house brand erasers at Walmart that were larger than average and would suit the dimensions required.

Another problem to sort out in the near future, is the 8PR actually presses flat against the inside rear of the first chamber. This means I have to get creative with regards to the added mass, the new chamber under the 8PR spider, and the depth allowed for xmax under operation. I have a stash of round 23 gram steel slugs that suit these PRs very well. I bore the centers, paint them, and install. This will take 3 slugs each, and will readily smack the inside box as it sits. I'll first try forstnering or boring a hole and gluing a flat across the inside to compensate. I may have to either bore holes through the PR frame underneath the spider, or route/cut some slots or notches where the rear of the frame meets to keep the air flow from making noise.

I haven't sealed or filled or finished the wood yet. I had to make the parts all fit first. There will be a lot of gasketing to seal the Lexan to the poplar.

InDIYana Event Website

Not using a drill press for countersinking with a drill bit is risky business, as you found out.

Speakers look neato!!

When I'm feeling lazy I use finish washers. I think they look good and are simple to use.

It is really hard to bore in the edge of the material in this case, but I needed to. I had no way to facilitate this with the press. The thing I learned with this Lexan material is to back it out more often whilst drilling, and don't stop until the bit is out of the pilot hole. I think the plastic melted and then resolidified, locking the bit in place. If this isn't what happened, the bit was just cheap or old. The chuck spun on it, and then it just snapped when I locked it back down. I am going to try and fill around the bit with epoxy, dripping it in the hole, but I'm not expecting miracles.

When I use flush head bolts or screws with plastic materials, I like to recess them so they don't stick out above the surface. I have a bit for such a task, and it works really well.

InDIYana Event Website

And I was just thinking in retrospect, I could have just cut holes in the plastic side panels for 2x more DSA135-PRs, and the design likely would have been fine. I'm hoping the 8PR cancels the motion of the active driver at least a little, while the side PRs balance their own forces quite readily.

Oh well, another trip around the barn backwards to find the door for me, only to find the door was locked. At least it looks good and will work.

InDIYana Event Website